Method for making let-off tension adjusting deformation cam roller

A technology of warp let-off tension and production method, which is applied in cams, belts/chains/gears, textiles, etc., can solve the problems of single color of woven fabrics, improve the grade of the variety, and realize the effect of changing the weft density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method for making warp let-off tension-adjusting deformed cam rollers, including cam base circle profile curve parameter design, cam apex profile curve design, and transition profile curve design from base circle profile curve to cam apex profile curve; the diameter of cam base circle is preferably 20mm ;The diameter of the cam tip profile is 2~4 times of the cam base circle diameter; the design of the transition profile curve from the base circle profile curve to the cam tip profile curve is mainly related to the rate change of the let-off variable, from the base circle profile curve to the cam tip The transition profile curve of the contour curve is a variable downward or upward curve X, which is reflected in the change of the let-off amount: normal let-off amount±[(distance between two tension rollers / 2) 2 +X 2 ] 1 / 2 ×2.

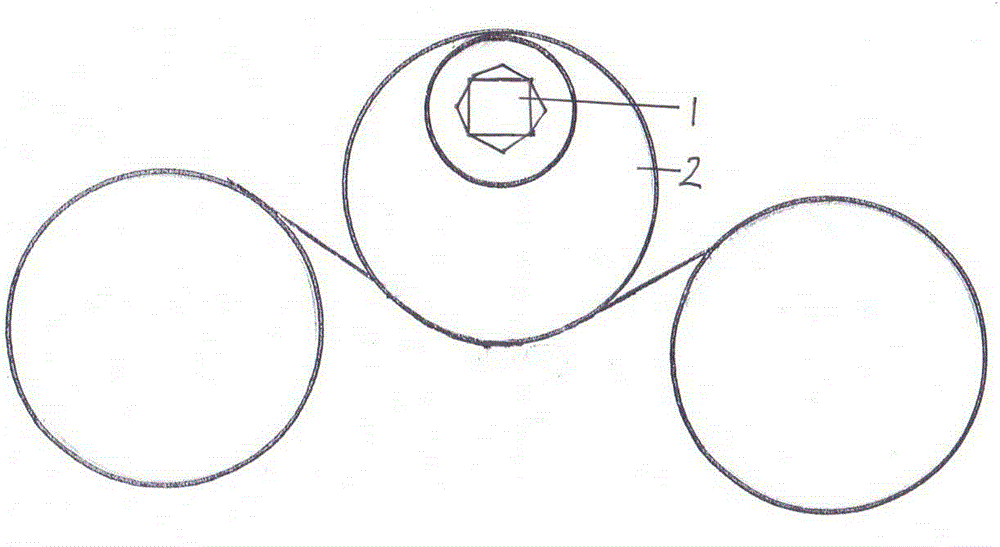

[0014] The axial combination design of the section of the cam is to divide the deformed cam roller into a base roller 1 and a cam body 2, and ...

Embodiment 2

[0021] A method for making warp let-off tension-adjusting deformed cam rollers, including cam base circle profile curve parameter design, cam apex profile curve design, and transition profile curve design from base circle profile curve to cam apex profile curve; the diameter of cam base circle is preferably 30mm ;The diameter of the cam tip profile is 2~4 times of the cam base circle diameter; the design of the transition profile curve from the base circle profile curve to the cam tip profile curve is mainly related to the rate change of the let-off variable, from the base circle profile curve to the cam tip The transition profile curve of the contour curve is a variable downward or upward curve X, which is reflected in the change of the let-off amount: normal let-off amount±[(distance between two tension rollers / 2) 2 +X 2 ] 1 / 2 ×2.

[0022] The axial combination design of the section of the cam is to divide the deformed cam roller into a base roller 1 and a cam body 2, and ...

Embodiment 3

[0029] A method for making warp let-off tension-adjusting deformed cam rollers, including cam base circle profile curve parameter design, cam apex profile curve design, and transition profile curve design from base circle profile curve to cam apex profile curve; the diameter of cam base circle is preferably 35mm ;The diameter of the cam tip profile is 2~4 times of the cam base circle diameter; the design of the transition profile curve from the base circle profile curve to the cam tip profile curve is mainly related to the rate change of the let-off variable, from the base circle profile curve to the cam tip The transition profile curve of the contour curve is a variable downward or upward curve X, which is reflected in the change of the let-off amount: normal let-off amount±[(distance between two tension rollers / 2) 2 +X 2 ] 1 / 2 ×2.

[0030] The axial combination design of the section of the cam is to divide the deformed cam roller into a base roller 1 and a cam body 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com