Shock-absorbing steel structural joint member

A steel structure and node technology, applied in building components, earthquake resistance, building structure, etc., can solve the problems of unreasonable structural design, easy breaking of bolts, poor safety, etc., to enhance safety, protect bolts, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

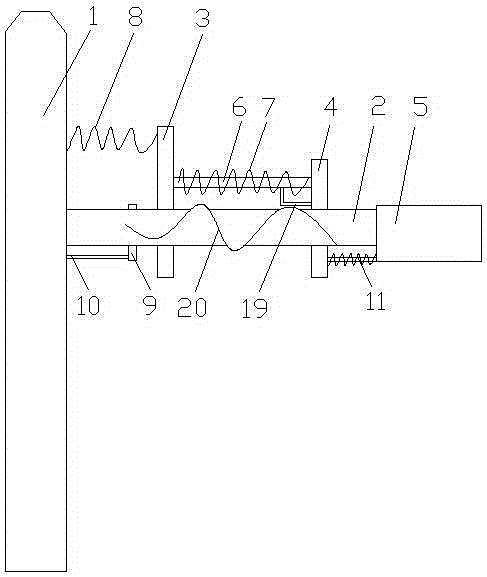

[0033] see figure 1 , a shock-absorbing steel structure node component, including a steel column 1, a channel steel 2, a backing plate 3, a connecting plate 4 and a truss chord 5, one end of the channel steel 2 is connected to the steel column 1, and the other end is connected to the truss chord 5 connection, the channel steel 2 runs through the backing plate 3 and the connecting plate 4 in turn, the backing plate 3 and the connecting plate 4 are connected by bolts 6, the bolts 6 are covered with springs 7, and the backing plate 3 and the steel column 1 pass through The tension spring 8 is connected, the channel steel 2 is covered with a ring 9, and the ring 9 is provided with a stay rope 10, and the circle 9 is connected with the steel column 1 through the stay rope 10, and the connecting plate 4 is connected with the truss string A spring column 11 is arranged between the rods 5, one end of the spring column 11 is connected with the connecting plate 4, and the other end is c...

Embodiment 2

[0036] see figure 2 , a shock-absorbing steel structure node component, including a steel column 1, a channel steel 2, a backing plate 3, a connecting plate 4 and a truss chord 5, one end of the channel steel 2 is connected to the steel column 1, and the other end is connected to the truss chord 5 connection, the channel steel 2 runs through the backing plate 3 and the connecting plate 4 in turn, the backing plate 3 and the connecting plate 4 are connected by bolts 6, the bolts 6 are covered with springs 7, and the backing plate 3 and the steel column 1 pass through The tension spring 8 is connected, the channel steel 2 is covered with a ring 9, and the ring 9 is provided with a stay rope 10, and the circle 9 is connected with the steel column 1 through the stay rope 10, and the connecting plate 4 is connected with the truss string A spring column 11 is arranged between the rods 5, one end of the spring column 11 is connected with the connecting plate 4, and the other end is ...

Embodiment 3

[0040] see image 3 , a shock-absorbing steel structure node component, including a steel column 1, a channel steel 2, a backing plate 3, a connecting plate 4 and a truss chord 5, one end of the channel steel 2 is connected to the steel column 1, and the other end is connected to the truss chord 5 connection, the channel steel 2 runs through the backing plate 3 and the connecting plate 4 in turn, the backing plate 3 and the connecting plate 4 are connected by bolts 6, the bolts 6 are covered with springs 7, and the backing plate 3 and the steel column 1 pass through The tension spring 8 is connected, the channel steel 2 is covered with a ring 9, and the ring 9 is provided with a stay rope 10, and the circle 9 is connected with the steel column 1 through the stay rope 10, and the connecting plate 4 is connected with the truss string A spring column 11 is arranged between the rods 5, one end of the spring column 11 is connected with the connecting plate 4, and the other end is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com