Lift car sill

A technology for sill and car, which is applied in the field of car sill, can solve the problems of incompatibility with energy-saving resources, complicated structure of climbing mechanism, cumbersome waste, etc., and achieve the effect of simple and sturdy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

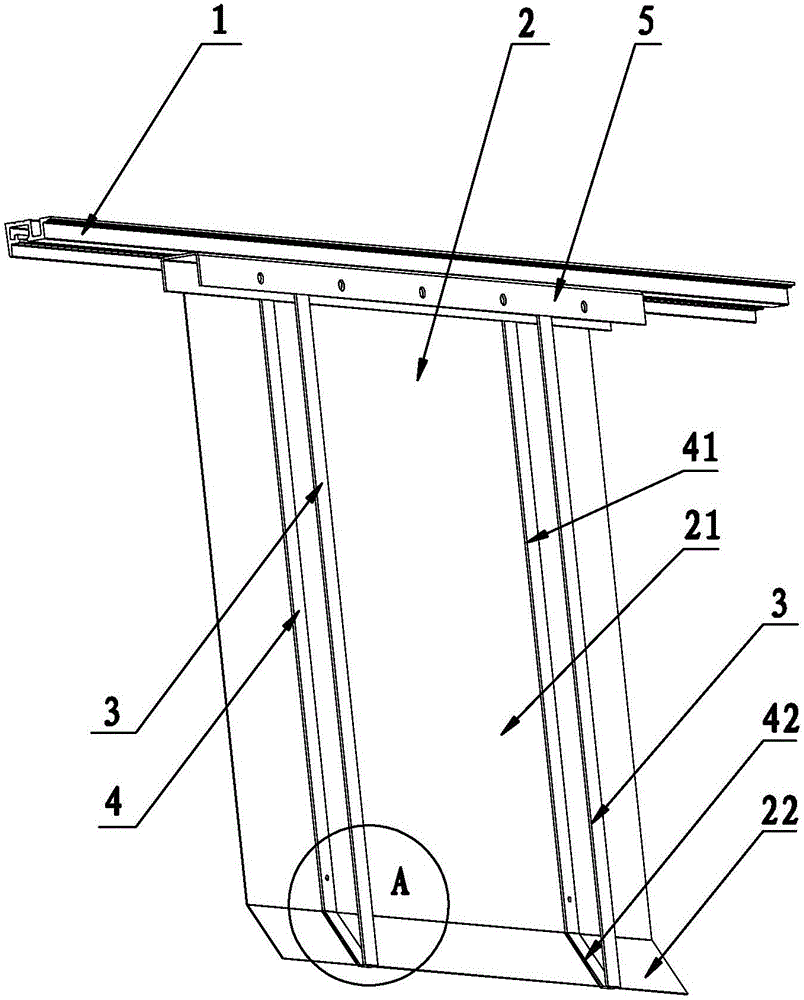

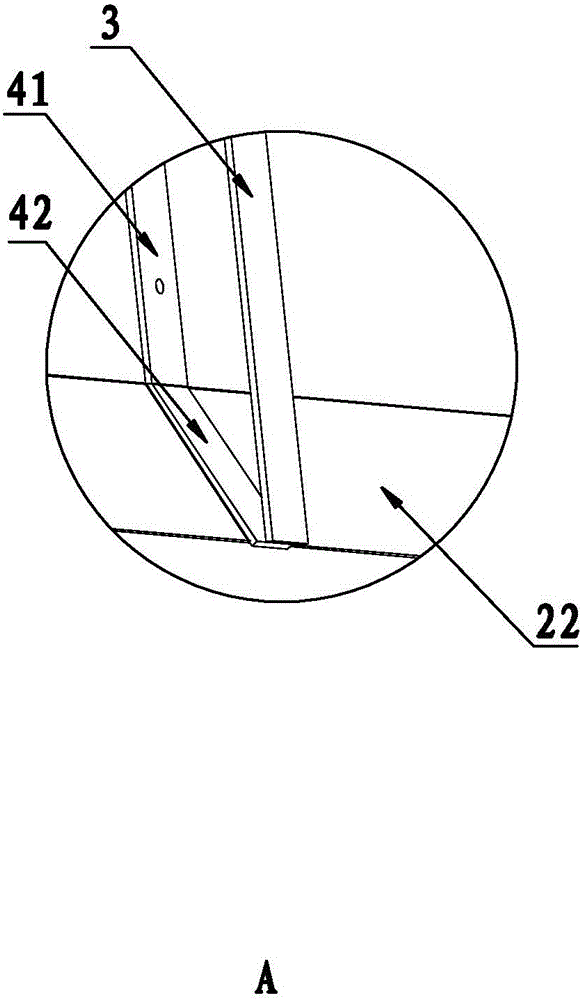

[0021] Such as Figure 1-2 As shown, a car sill includes a sill 1, a toe guard 2, a straight flat steel 3, a flat steel 4 and a channel frame 5, and the bottom surface of the sill 1 is equipped with the channel frame 5, The trough frame 5 is a U-shaped structure, the opening of the trough frame 5 faces downward, and the toe guard 2 is fixedly installed on the front end of the lower part of the trough frame 5, and the toe guard 2 includes a vertical plate 21 and an inclined Plate 22, the vertical plate 21 is fixedly installed on the front end of the lower part of the channel frame 5, and the inclined plate 22 is integrally arranged on the bottom surface of the vertical plate 21;

[0022] The flattened steel 4 is fixedly installed on the inner side of the bottom of the channel frame 5. The flattened steel 4 includes a vertical steel 41 and an oblique steel 42. The front end of the vertical steel 41 is connected to the rear of the vertical plate 21. The end face is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com