A circuit board assembly control system

A circuit board component and control system technology, applied to the circuit layout, elastic/clamping device, etc. on the support structure, can solve the imbalance of mechanical force on the circuit board, affect the wiring layout of the circuit board, affect the mechanical strength of the circuit board, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

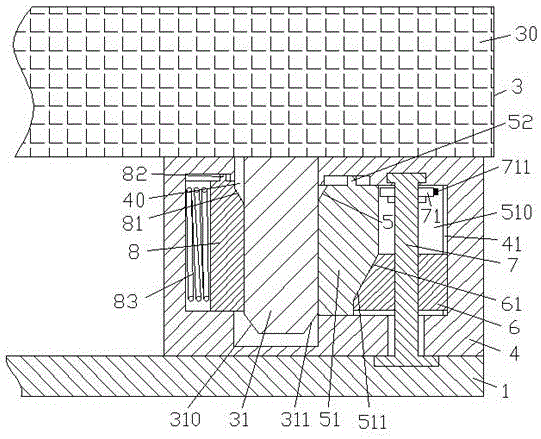

[0010] Combine below Figure 1-3 The present invention will be described in detail.

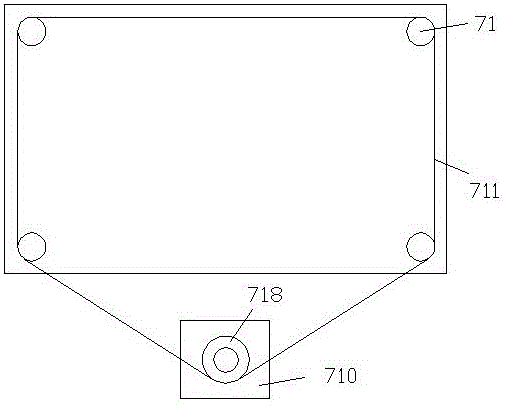

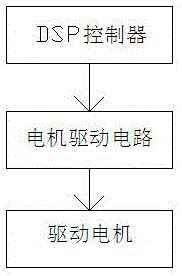

[0011] A circuit board assembly control system according to an embodiment includes a DSP controller, a motor drive circuit, and a circuit board assembly, wherein the circuit board assembly includes a circuit board device 3 and a base fixing device, and the circuit board device 3 includes Rectangular body portion 30 and four fixed feet 31 respectively located at the corners of the rectangle, the base fixing device includes a base 1 and is fixed on the base 1 and corresponds to the four fixed feet 31 respectively There are four mounting frames 4, the mounting frames 4 are provided with slots 40 for inserting the fixing feet 31, and the mounting frames 4 are inside the body part 30 of the slots 40 close to the circuit board device 3 The inner part of the inner part is provided with an inner clamping block 8 which is biased by a pressing spring 83 and can extend into the slot 40, and the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com