A small normally open high-speed clutch

A high-speed clutch, normally open technology, applied in the field of clutches, can solve the problems of unsuitable installation, inability to realize, large clutches, etc., achieving the effect of simple principle and structure, and solving the problems of engagement and disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings.

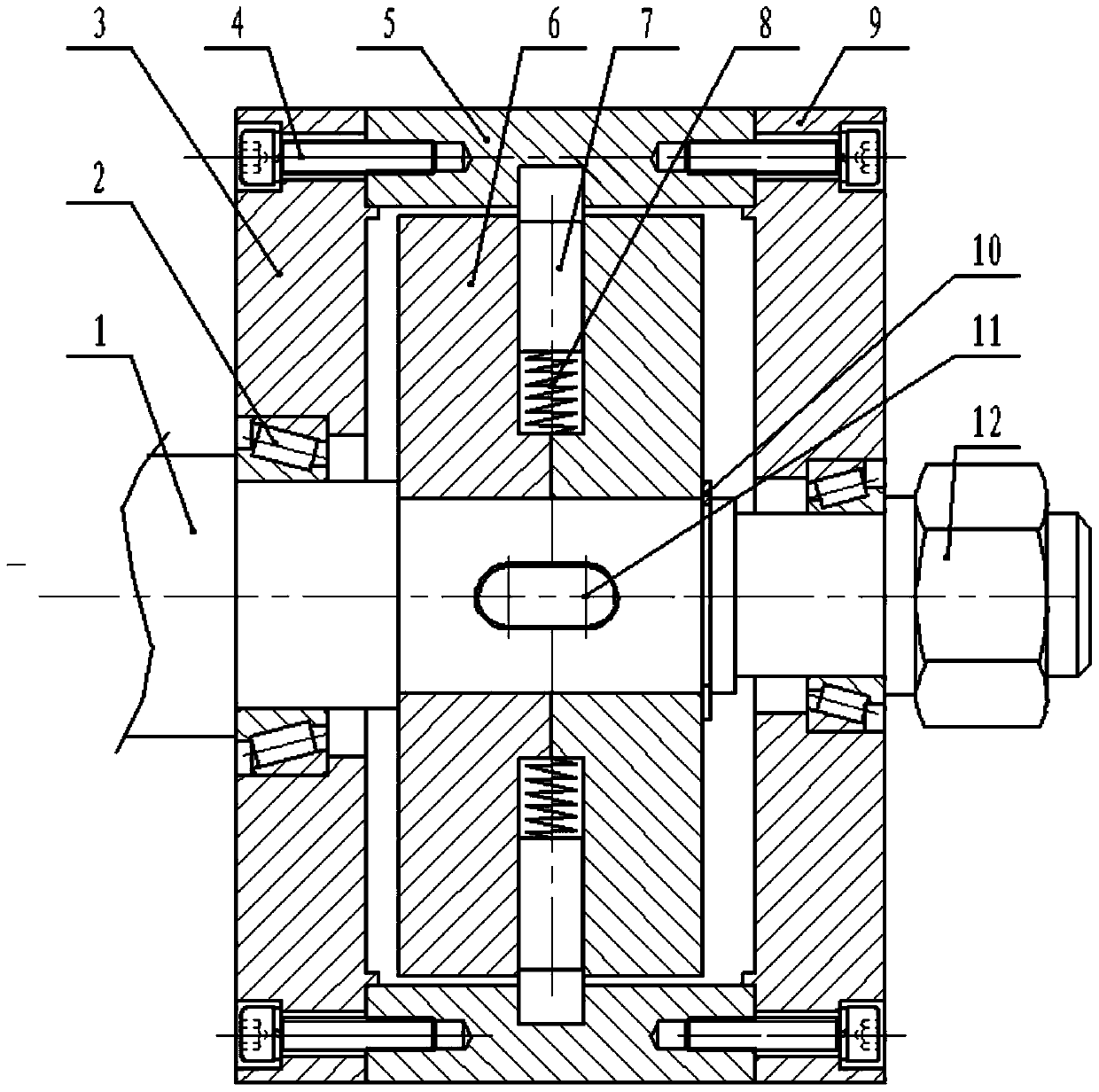

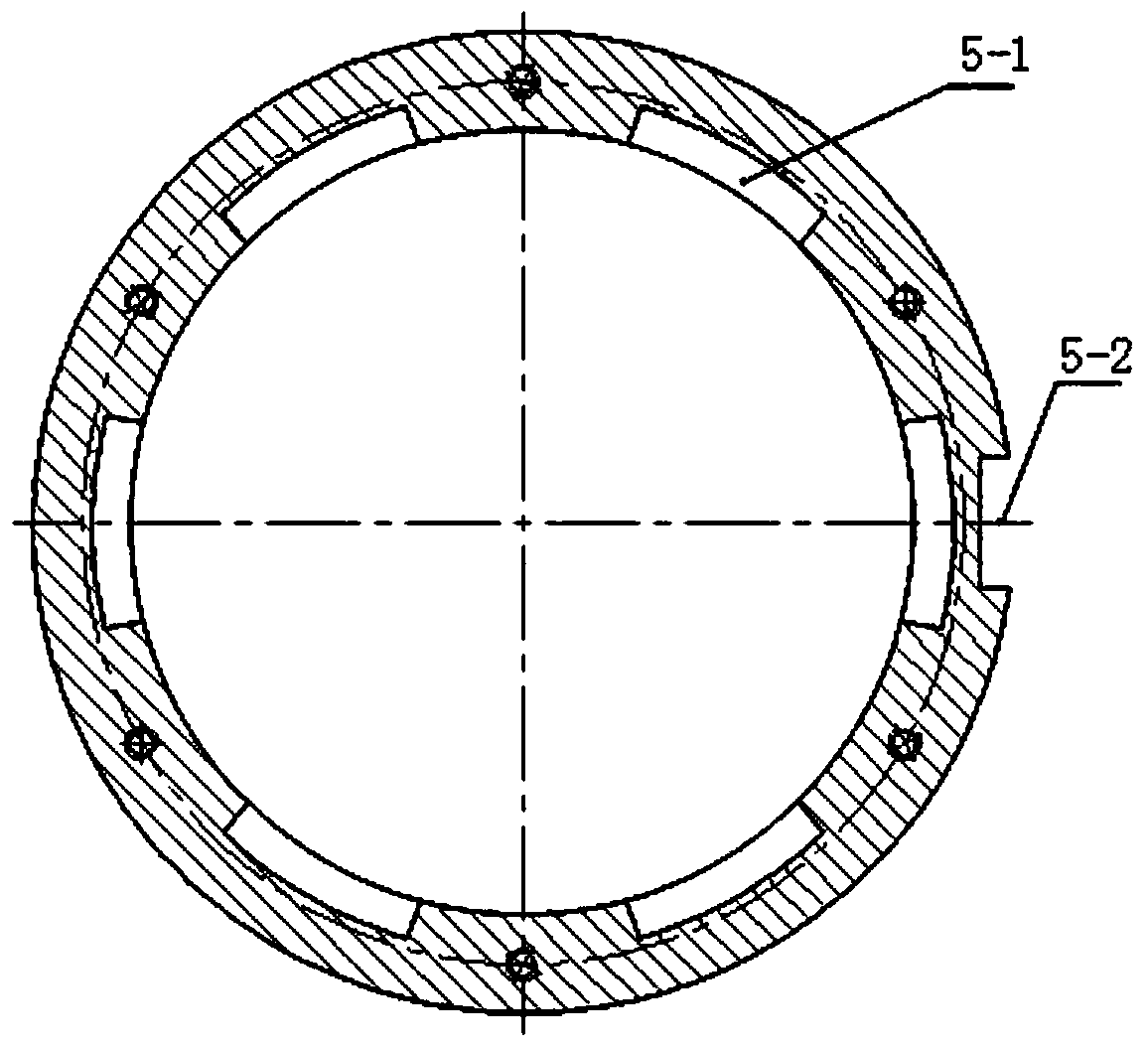

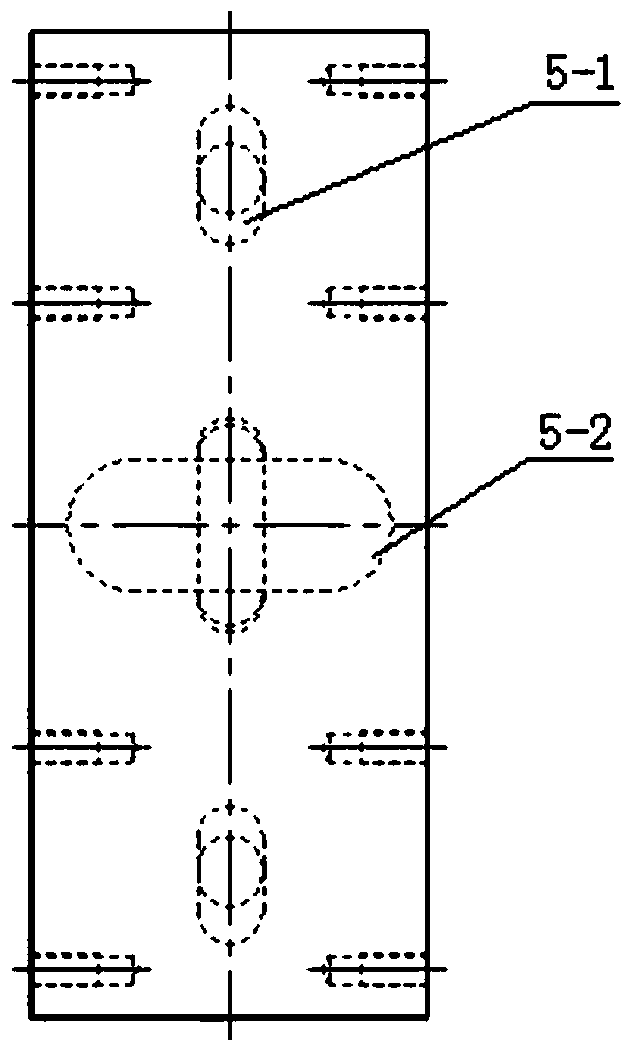

[0021] Such as Figure 1 to 3 As shown, the small normally open high-speed clutch of the present invention includes a clutch active part and a clutch driven part. The active part of the clutch includes a power input shaft 1, a key 11, a turntable 6, a cylindrical pin 7 and a tension spring 8. The power input shaft 1 and the center hole of the turntable 6 are connected by a key 11, and one end of the turntable 6 is provided with a shaft stopper. Ring 10, the shaft is fixed with the power input shaft 1 by the retaining ring 10, the power input shaft 1 and the turntable 6 are axially positioned through the shaft retaining ring 10, the outer circular surface of the turntable 6 is provided with a cylindrical pin hole, and the cylindrical pin hole is provided The cylindrical pin 7 is connected to the bottom of the cylindrical pin hole by a tension spring 8. The clutch driven part includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com