Bird egg sorting device

A sorting device and egg technology, applied in packaging, packaging food, packaging protection, etc., can solve the problems of low continuity, poor energy, limited speed, etc., achieve fast sorting speed, ensure good product rate, occupy small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention be further understood, the present invention will be further described below with reference to accompanying drawing and specific embodiment of description:

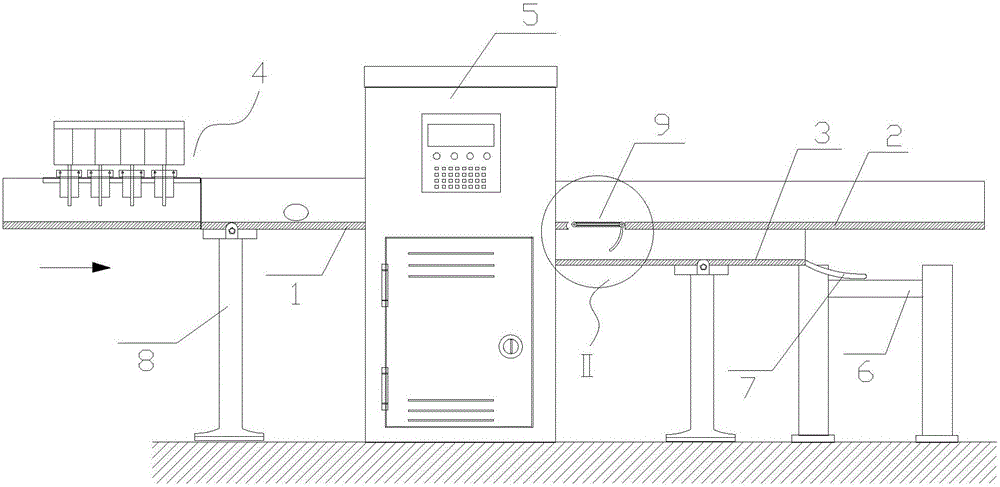

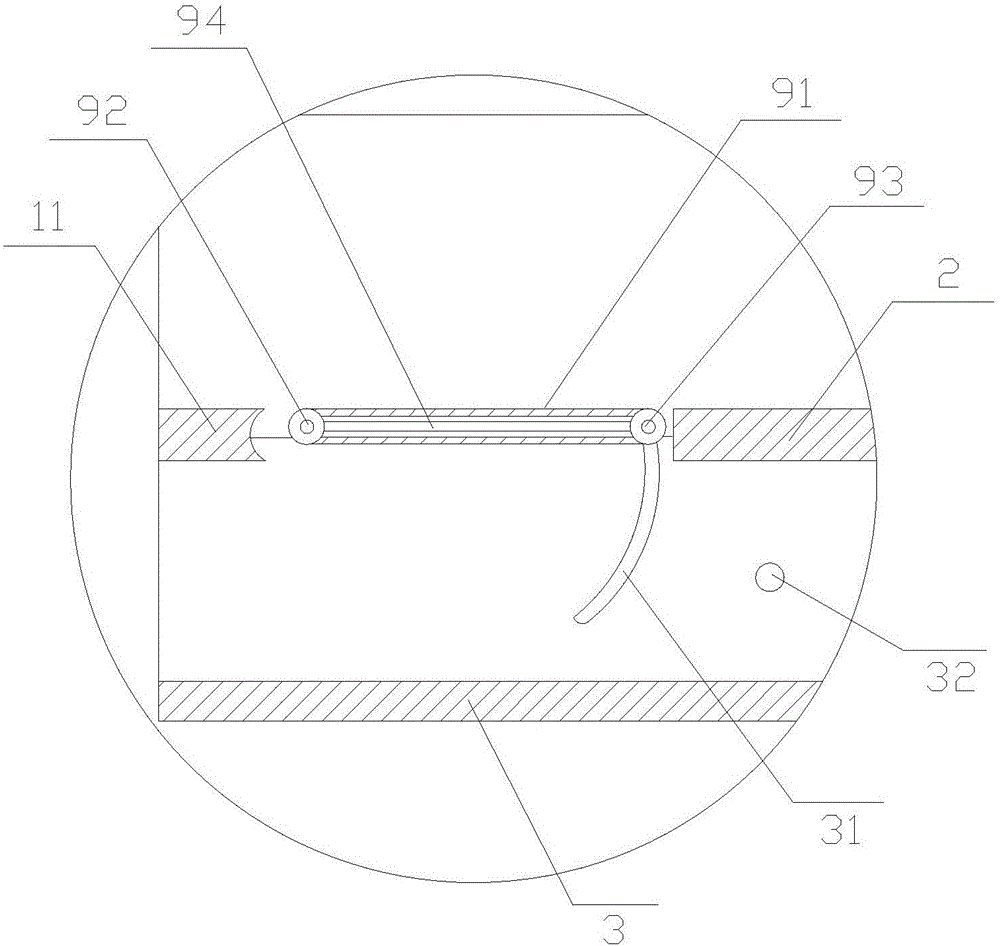

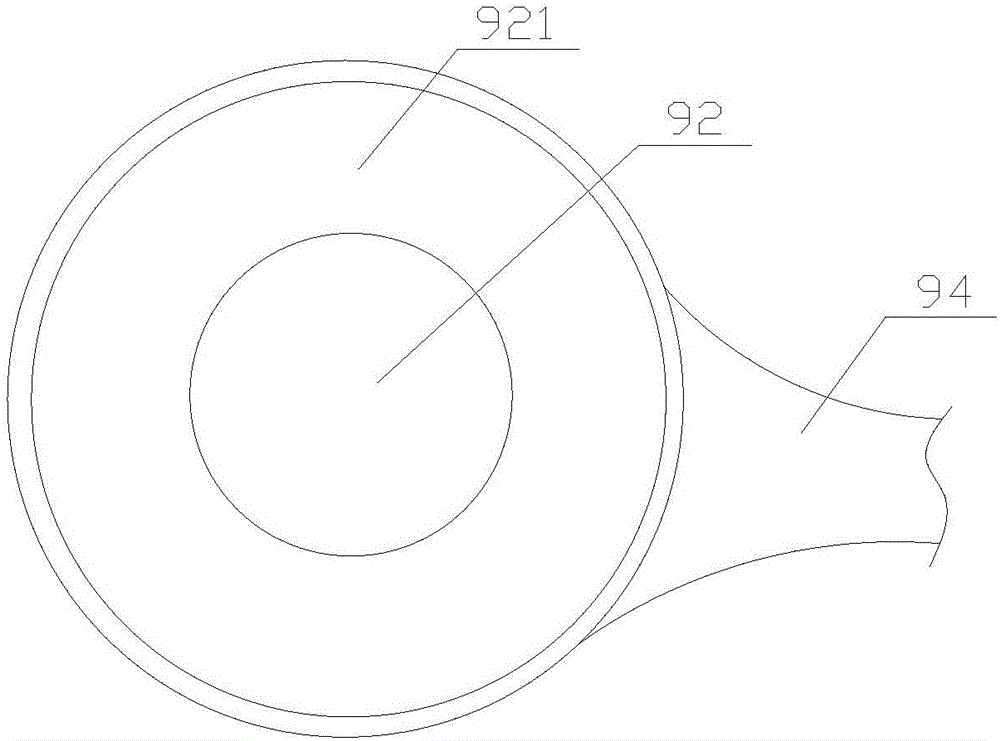

[0020] Such as Figure 1 to Figure 5 As shown, a poultry and egg sorting device includes an upper conveyor belt composed of a front conveyor belt 1 and a rear conveyor belt 2. The upstream end of the front conveyor belt 1 is provided with an automatic sorting system 4. The automatic sorting system 4 is used for The purpose is to output the poultry eggs initially selected by the upstream automatic egg harvester on the front conveyor belt 1 at intervals, even if there is a certain distance between the front and back adjacent poultry eggs, so that the subsequent detection equipment can operate normally without disorder . The poultry eggs initially selected from the upstream automatic egg harvester have two states, one is the good-quality poultry eggs with intact eggshells withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com