Automatic control system and control method of rubber cylinder surface cleaning device of offset printing machine

An automatic control system and rubber roller technology, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of inability to guarantee the cleaning effect of printing machine rollers, laborious cleaning methods, and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

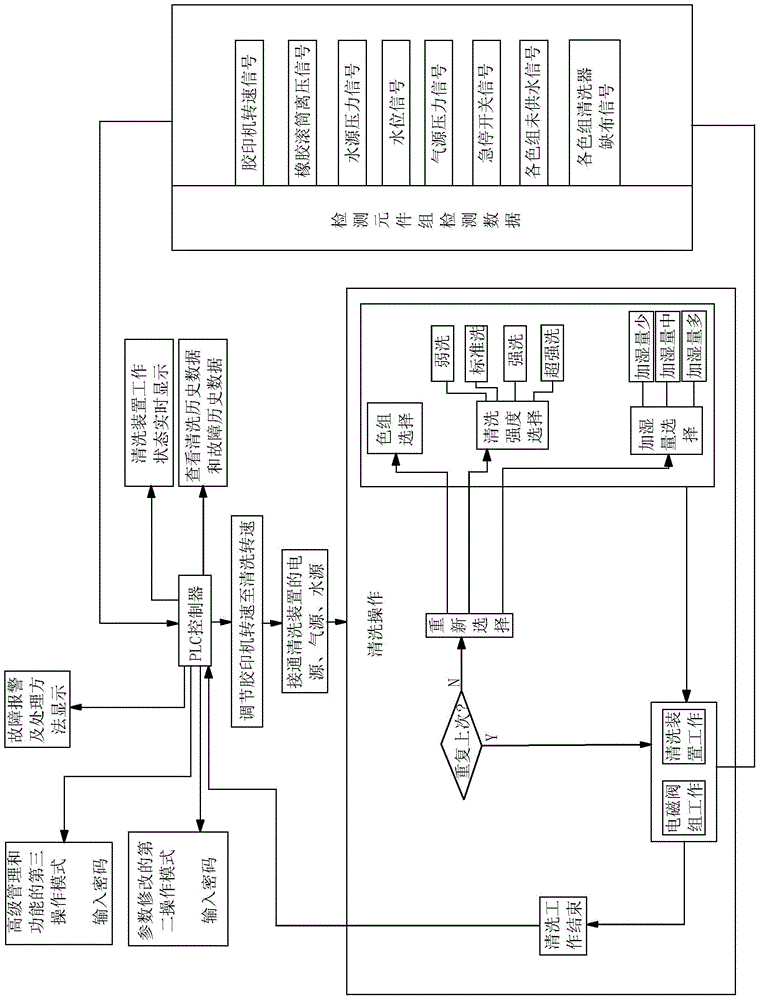

[0056] Knownly, there are usually a plurality of color groups in an offset printing machine, and a washer 8 is installed in each color group, and the washer 8 is arranged next to the rubber cylinder. During the cleaning process of the rubber cylinder by the washer 8, the washer 8 The middle cleaning cloth is in contact with the rubber roller, spray cleaning water on the cleaning cloth, and clean the ink stain on the surface of the rubber roller with the rotation of the rubber roller.

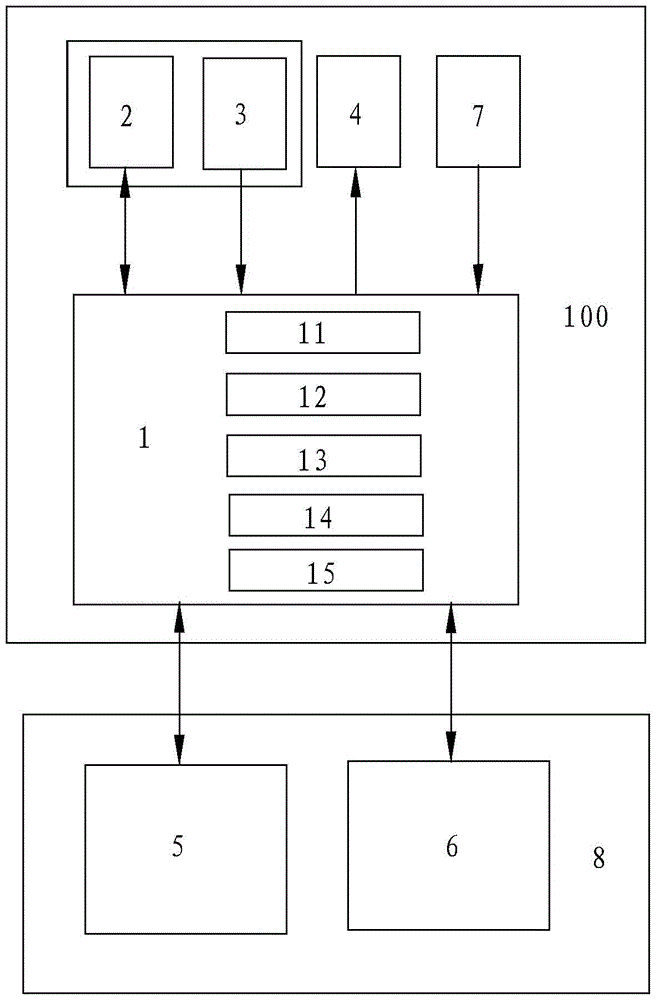

[0057] Such as figure 1 As shown, the automatic control system of the rubber cylinder surface cleaning device of the offset printing machine in this embodiment is connected with the corresponding cleaner 8 in each color group in the offset printing machine, so as to control the cleaners 8 in each color group to complete the surface cleaning of the rubber cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com