viticulture shed

A technology for cultivation sheds and grapes, which is applied in the field of grape cultivation sheds, which can solve the problems of unfavorable grape seedlings to absorb mineral elements, low ground utilization rate, and poor ventilation conditions, so as to facilitate respiration and photosynthesis, high utilization rate of planting area, Facilitate the absorption of mineral elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

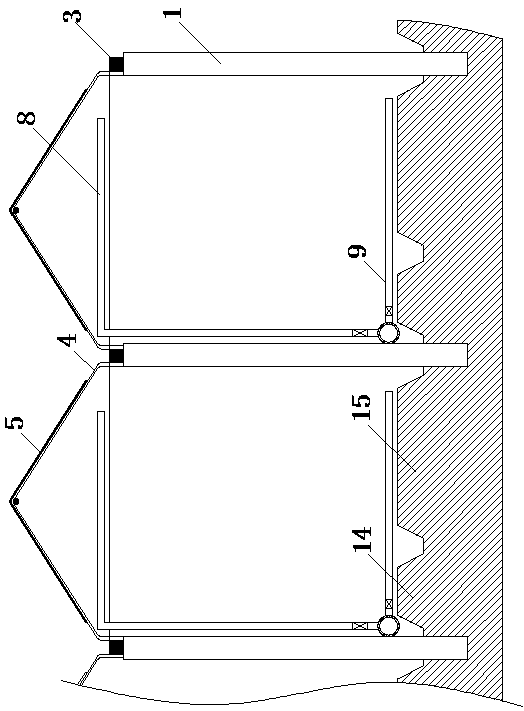

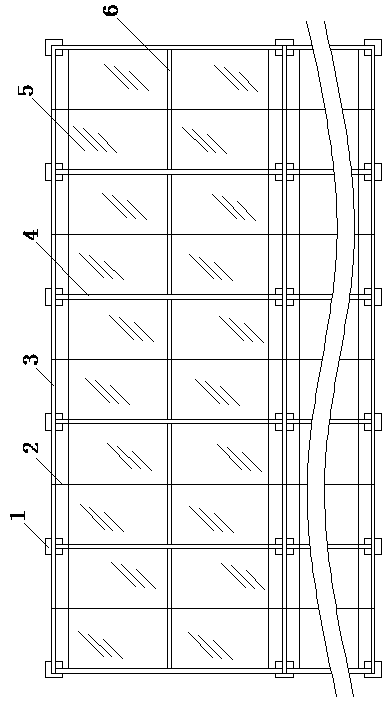

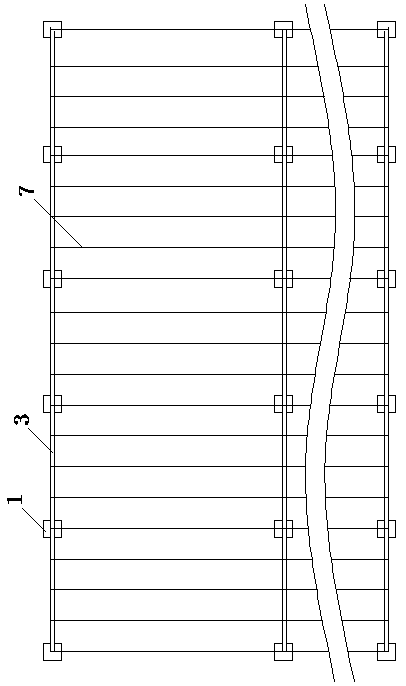

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the viticulture shed of the present invention includes columns 1 arranged in rows and columns and a roof fixed on the columns 1, and also includes a climbing frame for grape seedlings and a planting area. The row spacing of column 1 is 500cm. The preferred range value of the line spacing of the column 1 is 450-800cm. The column pitch of column 1 is 200cm. The preferred range of column spacing of the columns 1 is 150-320cm. The ceiling includes film supporting rods 4 , fixing rods 3 , connecting rods 6 , film covering 5 and film pressing belt 2 . The membrane support rod 4 is connected by two chord rods to form a "∧" shape. The "∧"-shaped film support rods 4 are arranged in rows and the distance between the two ends is adapted to the row spacing of the columns 1 . The distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com