Cyclone device

A technology of cyclone separator and swirling airflow, applied in cyclone devices, separation methods, combined devices, etc., can solve problems such as speed reduction, and achieve the effect of improving powder collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

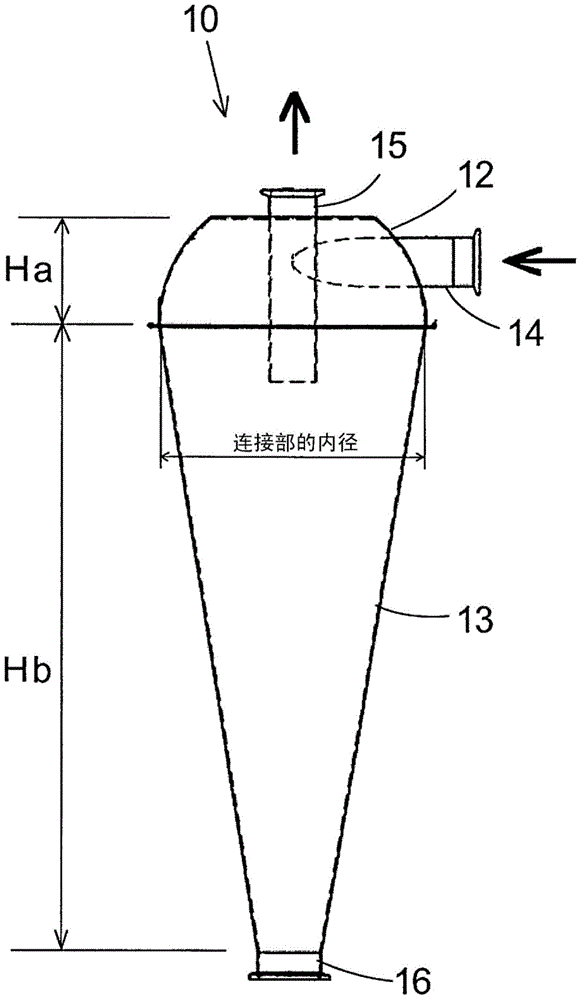

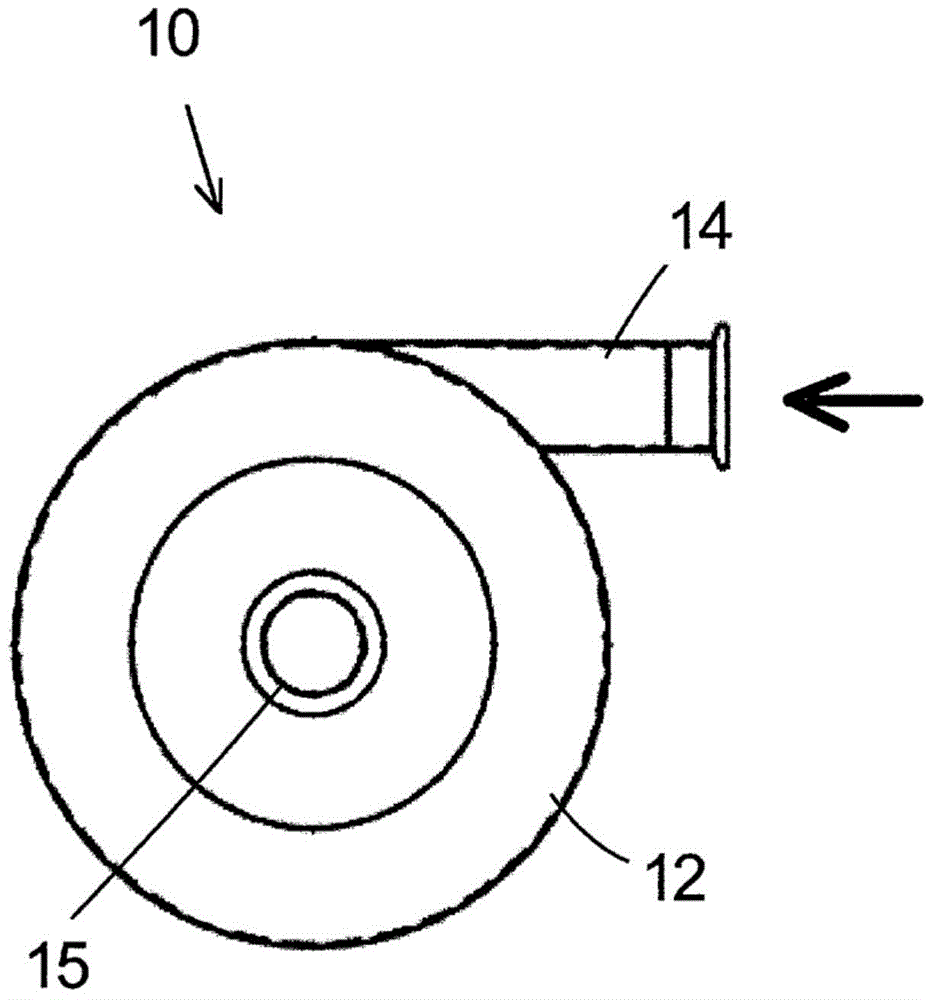

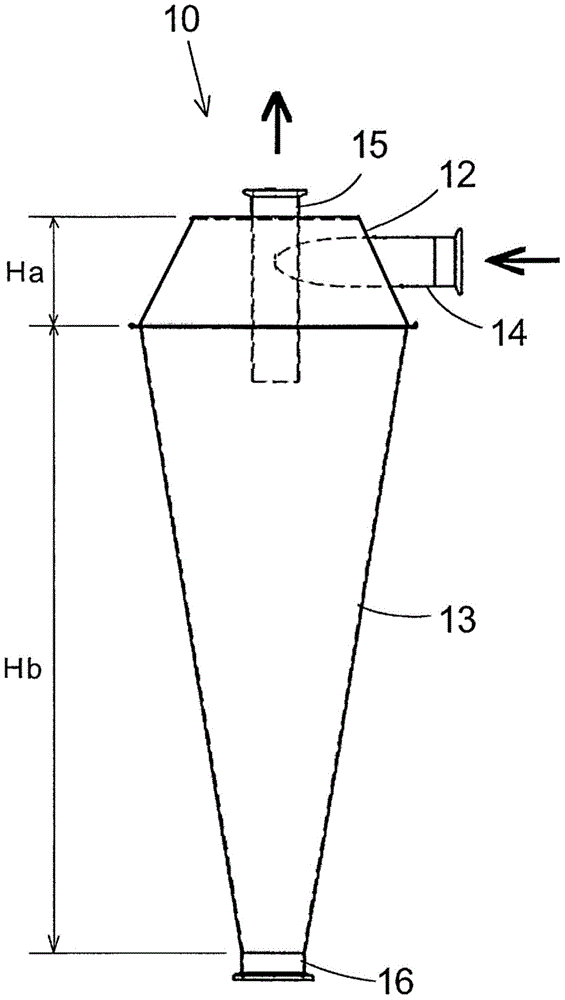

[0048] Hereinafter, the cyclone device according to the first embodiment of the present invention will be described with reference to the drawings.

[0049] Such as figure 1 with figure 2 As shown, the cyclone device 10 of this embodiment includes an airflow introduction section 12 with an upper structure and a tapered section 13 with a lower structure.

[0050] The airflow introducing section 12 has a hemispherical internal structure with a diameter gradually expanding downward. The airflow containing powder is introduced from the airflow introducing portion 14 provided at one end of the airflow introducing section 12 in the tangential direction of the airflow introducing section 12, and thus along the A whirling airflow is generated on the inner wall surface of the airflow introducing section 12.

[0051] The tapered section 13 of the lower structure is connected to the lower end of the hemispherical air flow introducing section 12 and has an inverted cone-shaped internal structu...

no. 2 Embodiment

[0090] Next, the second embodiment of the present invention will be described.

[0091] Image 6 Is a front cross-sectional view showing the cyclone device 110 of this embodiment, Figure 7 Is its top view.

[0092] As shown in these figures, the cyclone device 110 of this embodiment includes: an airflow introduction section 112, which is hemispherical and gradually expands its diameter downward; and a tapered section 113, which is in an inverted cone shape and is connected to the airflow introduction section. The lower end is connected with the lower end and the diameter is gradually reduced downward; and the powder collection section 116 is connected with the lower end of the tapered section 113.

[0093] In this embodiment, the airflow introduction section 112 is also provided with: an airflow introduction part 114, which is used to introduce the airflow containing powder into the device; and an airflow discharge part 115, which is used to complete the separation of the powder. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com