Auxiliary debugging system for station level equipment of intelligent substation

A technology for smart substations and debugging systems, applied in the field of smart substations, can solve problems such as cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

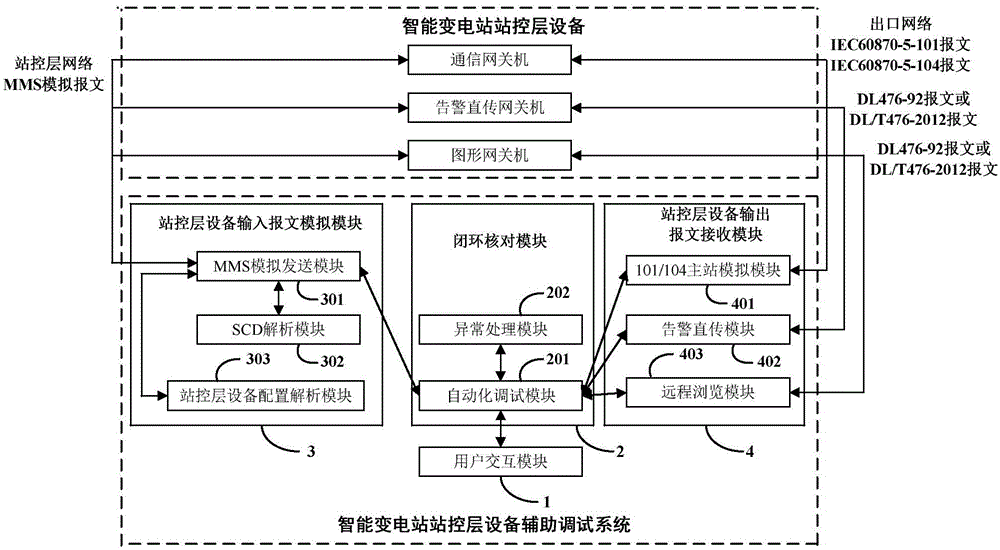

[0015] figure 1 It is a principle block diagram of a specific implementation mode of the intelligent substation station control layer equipment auxiliary debugging system of the present invention.

[0016] In this example, if figure 1 As shown, the intelligent substation station control layer equipment auxiliary debugging system of the present invention includes a user interaction module 1, a closed-loop verification module 2, a station control layer device input message simulation module 3 and a station control layer device output message receiving module 4. Each compone...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap