Permanent magnet synchronous motor convenient to install

A permanent magnet synchronous motor and output shaft technology, applied in electromechanical devices, transmission devices, gear transmission devices, etc., can solve the problems of increasing the assembly process of the production line, poor flexibility in spatial layout, structural design obstacles, etc., to eliminate assembly and design layout. Aspects of limitations, high flexibility, satisfying installation and use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

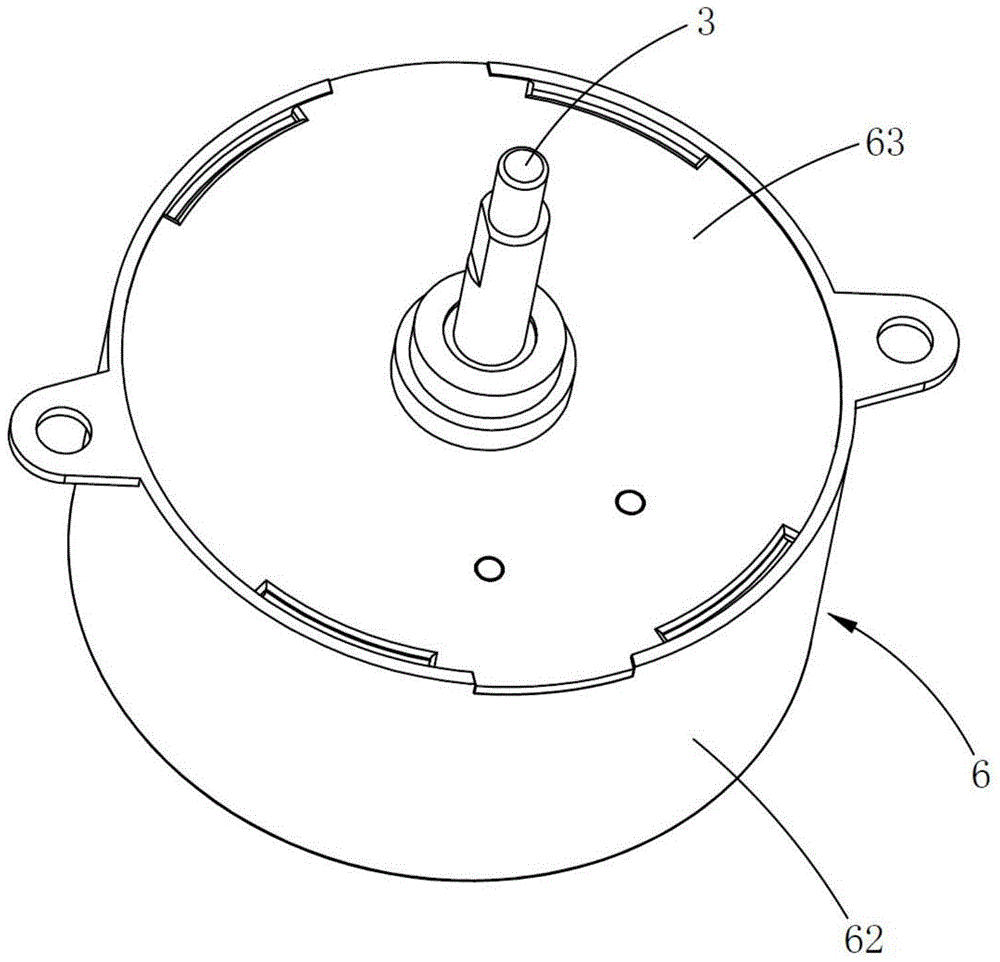

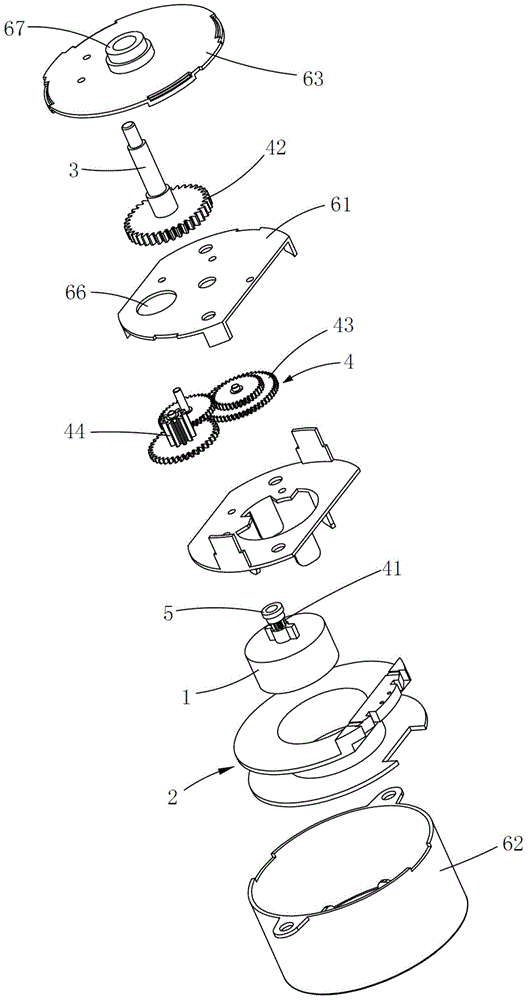

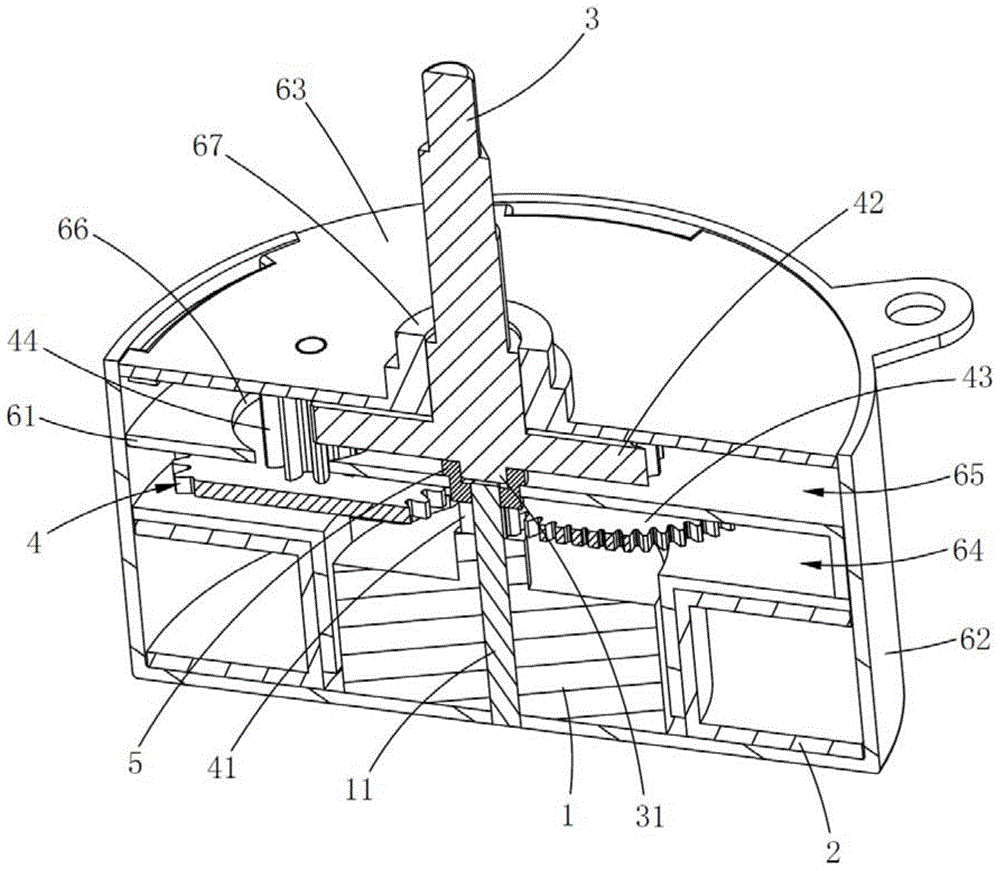

[0038] Embodiment, a kind of permanent magnet synchronous motor that is easy to install, see Figure 1 to Figure 3 As shown, it includes a housing 6, a first transmission gear set 4, a rotor 1, a stator 2 and an output shaft 3, the stator 2 is fixed in the housing 6, and a number of permanent magnets are installed in the outer ring area of the rotor 1, and the rotor 1 rotates Installed in the middle of the stator 2 , the rotor 1 is connected to the first transmission gear set 4 through the first gear 41 , and the lower end of the output shaft 3 is connected to the first transmission gear set 4 through the second gear 42 . Wherein, the housing 6 includes a bottom case 62 and a cover plate 63, the rotor 1 and the stator 2 are installed in the inner cavity of the bottom case 62, the cover plate 63 is assembled on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com