Liquid automatic detection method

An automatic detection, liquid technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of cumbersome operation, time-consuming, and complicated changing of the film, and achieve the effect of fast changing of the film and saving the liquid to be detected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

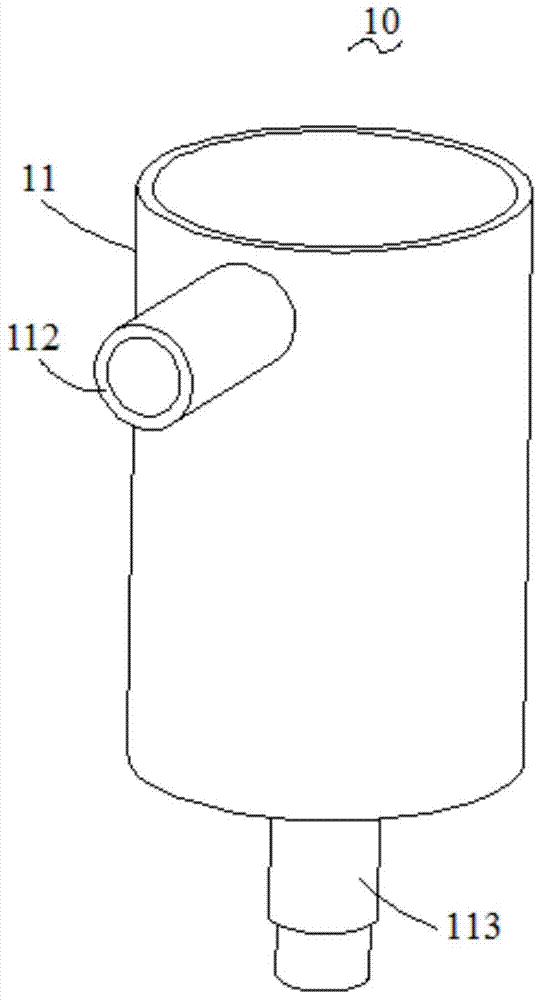

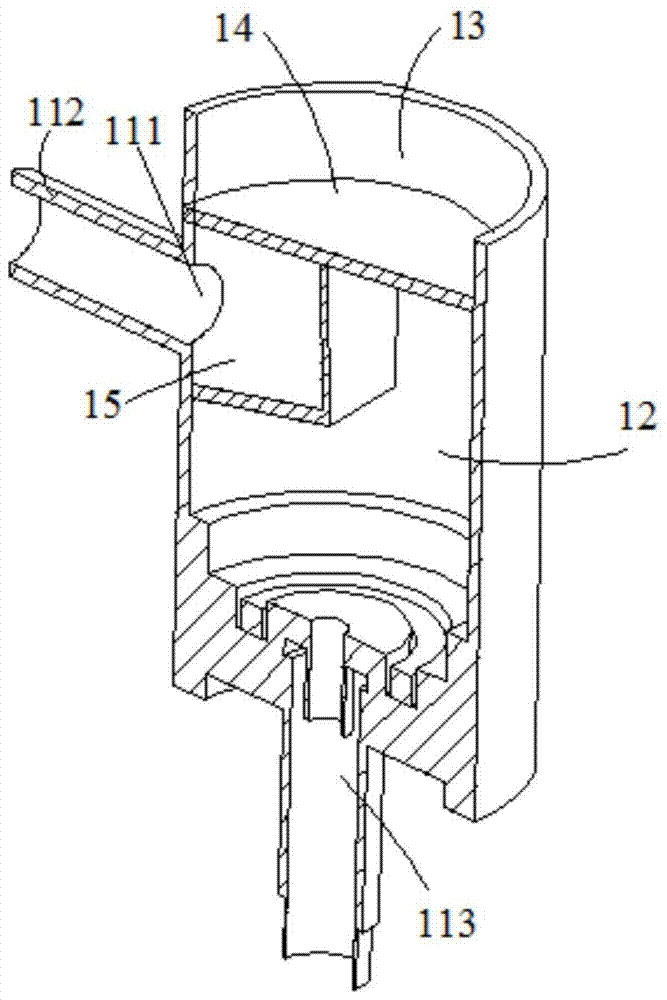

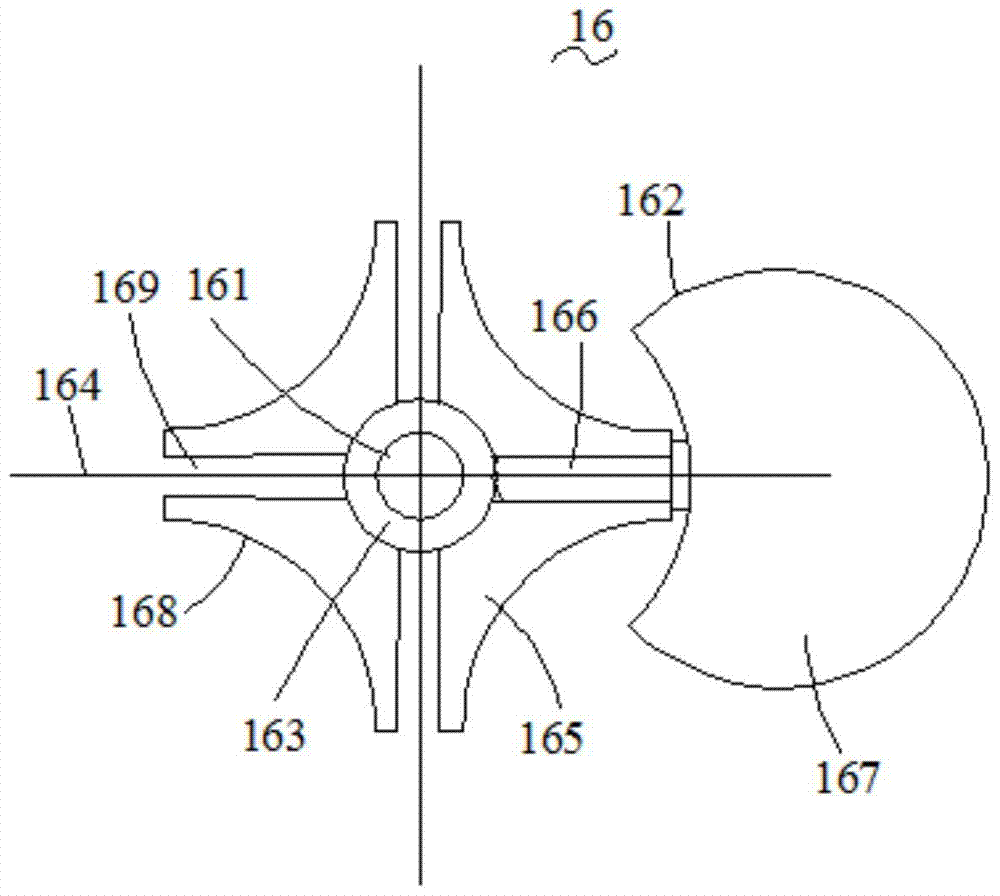

[0026] see Figure 1 to Figure 6 , a liquid detection system described in a preferred embodiment of the present invention includes a liquid detection device, a Raman spectrometer (not shown), a light trap (not shown), and signals from the Raman spectrometer and the light trap connected processor (not shown). The liquid detection device includes a liquid receiver 10 and a test pool 20 , the liquid receiver 10 communicates with the test pool 20 to introduce the liquid (not shown) in the liquid receiver 10 into the test pool 20 . The liquid receiver 10 includes a housing 11, a liquid storage chamber 12 and a transition chamber 13 formed in the housing 11, and a partition 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com