Novel aspergillus candidus production process

A technology of Hanoi white koji and production process, which is applied in the field of new Hanoi white koji production technology, can solve the problems of tertiary solid seeds susceptible to contamination, reduce the chance of secondary contamination, and reduce labor intensity, so as to reduce secondary contamination. opportunities for bacteria, low cost, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

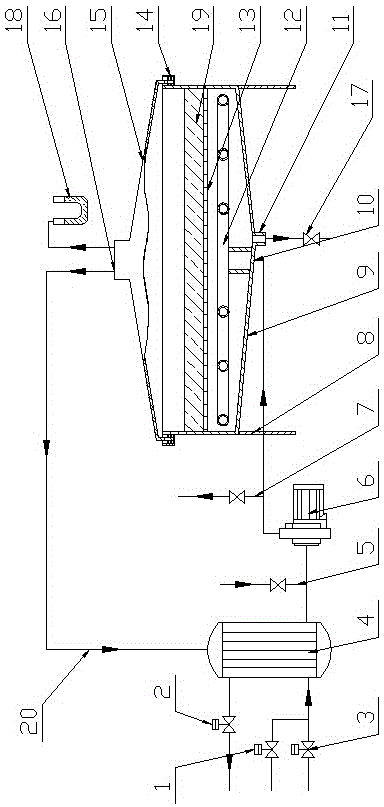

Image

Examples

Embodiment 1

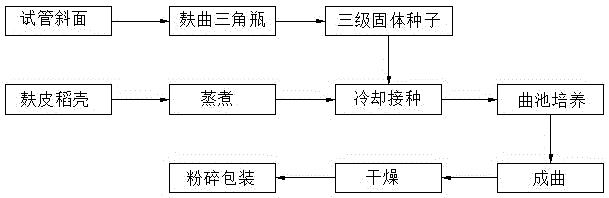

[0036] as attached figure 2 Shown, a kind of novel Hanoi white koji production technique of the present invention comprises following processing steps:

[0037] 1) Activation on test tube slant: inoculate the Hanoi alba koji on the sterilized test tube slant medium for activation, control the activation condition at 35°C for 4 days, and use it as the first-generation koji variety, wherein the test tube slant medium adopts 7 % malt juice agar medium, controlled sterilization conditions: 121°C, 40 minutes;

[0038] 2) Expansion culture of bran triangular flask: mix bran and water according to the mass ratio of 1:1 to make bran triangular flask culture medium, according to the proportion of 30g bran triangular flask culture medium per 500mL bran triangular flask, Divide into 500mL triangular flasks of glutinous rice, sterilize at 121°C for 25 minutes, shake up while hot and cool down, inoculate the first-generation koji species obtained in step 1) at an inoculation volume of 0....

Embodiment 2

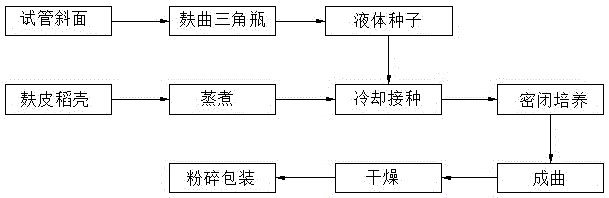

[0054] A kind of novel Hanoi white koji production technique of the present invention comprises following processing steps:

[0055] 1) Activation on test tube slant: inoculate Hanoi alba koji on a sterilized test tube slant medium for activation, control the activation condition at 34°C for 5 days, and use it as a first-generation koji variety. Among them, the test tube slant medium adopts a sugar content of 8 % malt juice agar medium, controlled sterilization conditions: 123°C, 42 minutes;

[0056] 2) Expansion of the bran triangular flask: mix the bran and water according to the mass ratio of 1:0.8 to make the bran triangular flask culture medium, according to the ratio of 35g bran triangular flask culture medium per 500mL bran triangular bottle, Divide into 500mL triangular flasks of glutinous rice, sterilize at 123°C for 35 minutes, shake up while hot and cool down, inoculate the first-generation koji species obtained in step 1) at an inoculation volume of 0.05% by volume...

Embodiment 3

[0064] A kind of novel Hanoi white koji production technique of the present invention comprises following processing steps:

[0065] 1) Activation on test tube slant: Inoculate Hanoi alba koji on a sterilized test tube slant medium for activation, control the activation condition at 38°C for 4.5 days, and use it as the first-generation koji species. Among them, the test tube slant medium adopts Brix 10 % malt juice agar medium, controlled sterilization conditions: 125°C, 45 minutes;

[0066] 2) Expansion culture of bran triangular flask: mix bran and water according to the mass ratio of 1:1.2 to make bran triangular flask culture medium, according to the proportion of 40g bran triangular flask culture medium per 500mL bran triangular bottle, Divide it into 500mL triangular flasks of glutinous rice, sterilize at 125°C for 40 minutes, shake it while it is hot and cool it down, inoculate the first-generation koji species obtained in step 1) with an inoculation volume of 0.1% by v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com