Double-flow-rate water cap unit element

A single-unit, flow-rate technology, applied in the field of dual-flow water cap unit-units, can solve problems such as the inability to satisfy the ratio between the backwash flow rate and the filtration flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

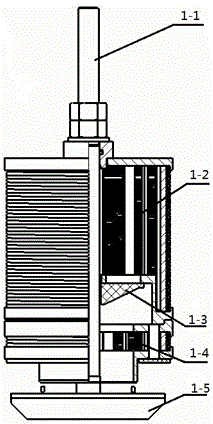

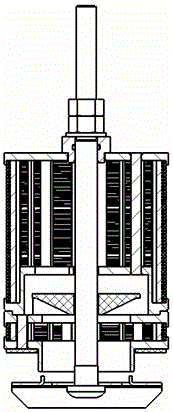

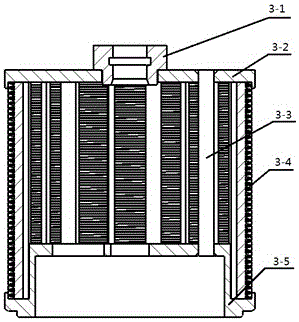

[0019] The device is composed of a high-speed flow part, a low-speed flow part, a square head screw, a valve core, a support block and a lock nut. The high and low speed flow parts are composed of upper and lower end covers, wire-wrapped screen tubes and tie rods for fastening the upper and lower end covers and screen tubes; the high speed flow parts are coaxial with the low speed flow parts, and the square head screw passes through The hole passes through, and the support block is placed on the other end of the water cap mounting plate, and is interlocked with the square end of the square head screw; the other end of the square head screw is a common thread, which is connected with the lock nut, and the high-speed through The flow part and the low-speed flow part are buckled on the water cap mounting plate; the valve core is placed between the high-speed flow part and the low-speed flow part through the square head screw rod, and can float up and down along the screw rod. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com