Yoga mat automatic cutter

A yoga mat and cutting machine technology, applied in the direction of object supply, metal processing, winding strips, etc., can solve the problems of yoga mat deformation, easy deviation of the transmission yoga mat, etc., and achieve accurate slicing, high work efficiency, and speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

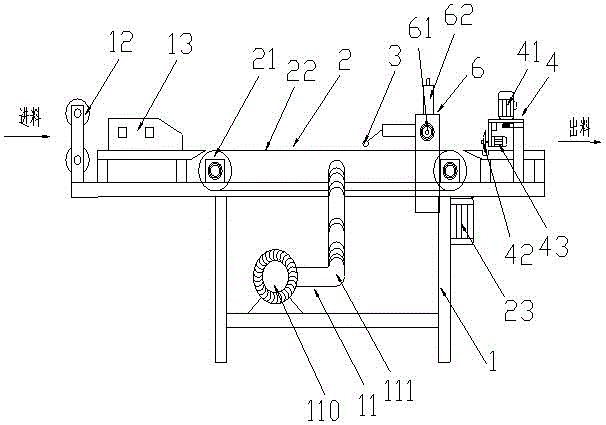

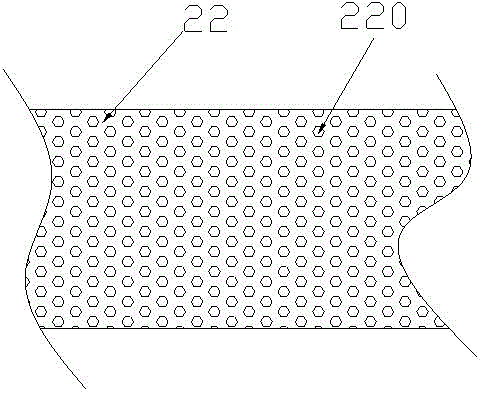

[0017] Such as figure 1 As shown, the present invention discloses a yoga mat automatic cutting machine, comprising a frame 1, a transmission mechanism 2, a metering device 3 and a cutter device 4; the transfer mechanism 2, the metering device 3 and the cutter device 4 are respectively On the frame 1; wherein, the cutter device 4 is located at the output end of the transmission mechanism 2; the frame 1 is also provided with a suction device 11, and the suction device 11 is installed in the inside of the frame 1, And located below the transmission mechanism 2, the interior of the transmission mechanism 2 is evacuated by the suction device 11, and then the yoga mat is absorbed and transported; the transmission mechanism 2 includes a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com