Jig frame used for cylindrical pile leg barrel submerged-arc welding

A submerged arc welding, cylindrical technology, applied in the direction of welding equipment, welding accessories, auxiliary welding equipment, etc., can solve the problems that the welding work cannot be guaranteed to be stable and stable, and the quality of cylindrical butt welding is unstable, so as to avoid multiple hoisting work, ensure welding efficiency, and reduce the effect of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

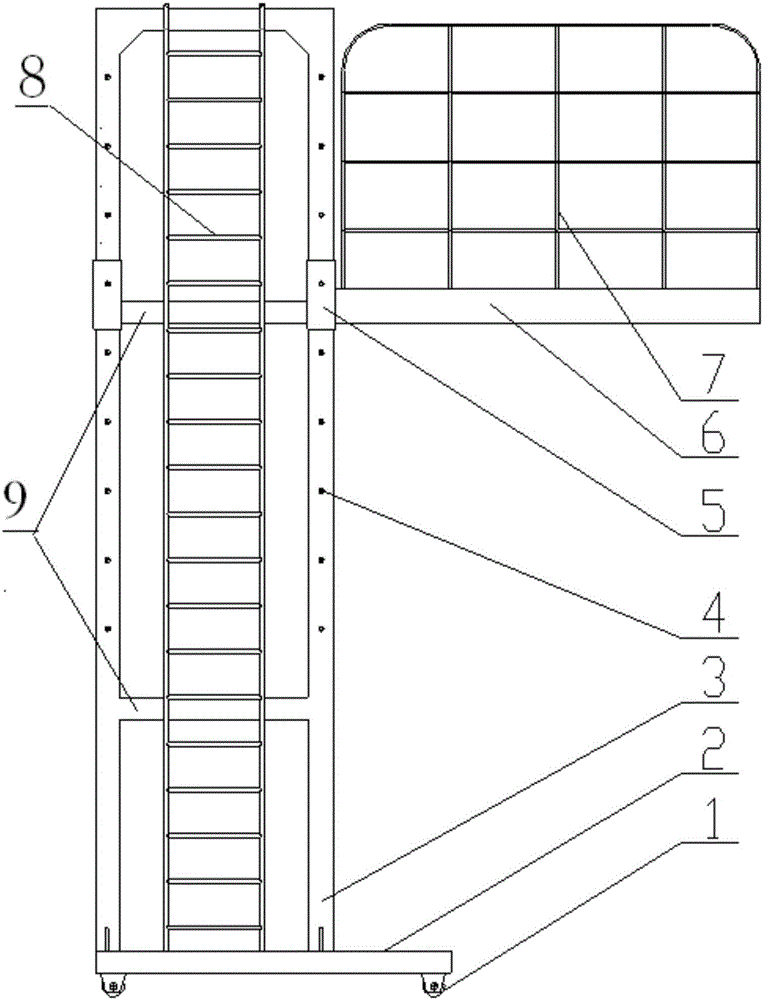

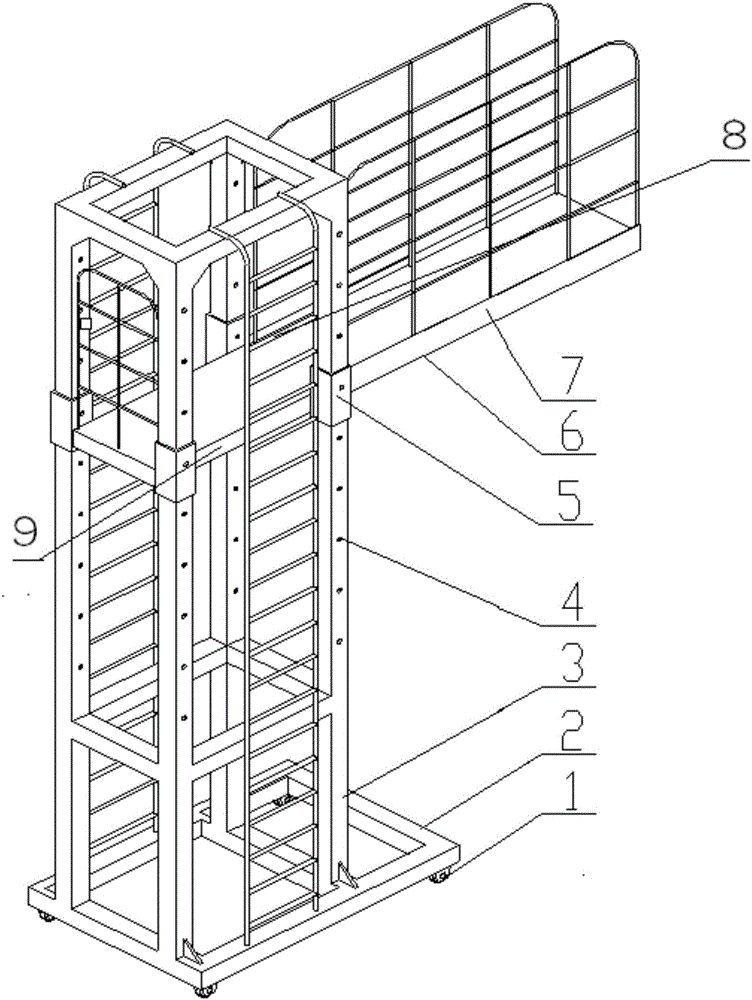

[0017] A cylindrical submerged arc welded tire frame for cylindrical pile legs includes a bottom universal wheel 1, a base 2, a height adjustable bracket 3, a height adjustment hole 4, a locking sleeve 5, an operating platform 6, a platform guardrail 7 and a climbing ladder 8 ; The support is a 3-square prism steel frame structure, the middle part is provided with reinforcing ribs 9, the universal wheel 1 of the base is installed on the base 2, and the height adjustable support 3 is fixedly connected with the base 2, so The height-adjustable bracket 3 is fixedly connected to the operating platform 6 through the height-adjusting hole 4 and the locking sleeve 5. The operating platform 6 is provided with a ladder 8. Before welding, according to the position of the welding seam of the cylinder, , the position of the operation platform 6 is moved through the height adjustment hole 4, and the operation platform 6 is fixed through the cooperation of the locking sleeve 5 and the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com