Hole-distance-controllable air-suction-type peanut hole-seeding wheel

An air-suction and hole-spacing technology, which is applied to the parts of the planter and the machinery for interval-type quantitative sowing, can solve the problems of troublesome loading and unloading and reinstallation, and the inability to change the number of seeds in each hole, etc., and achieves simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

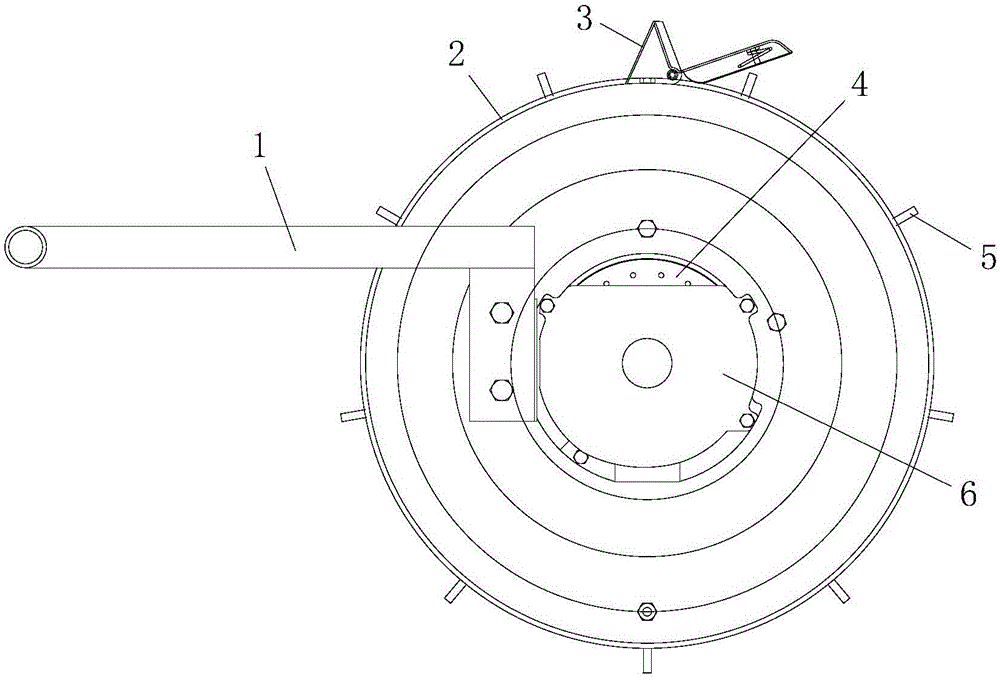

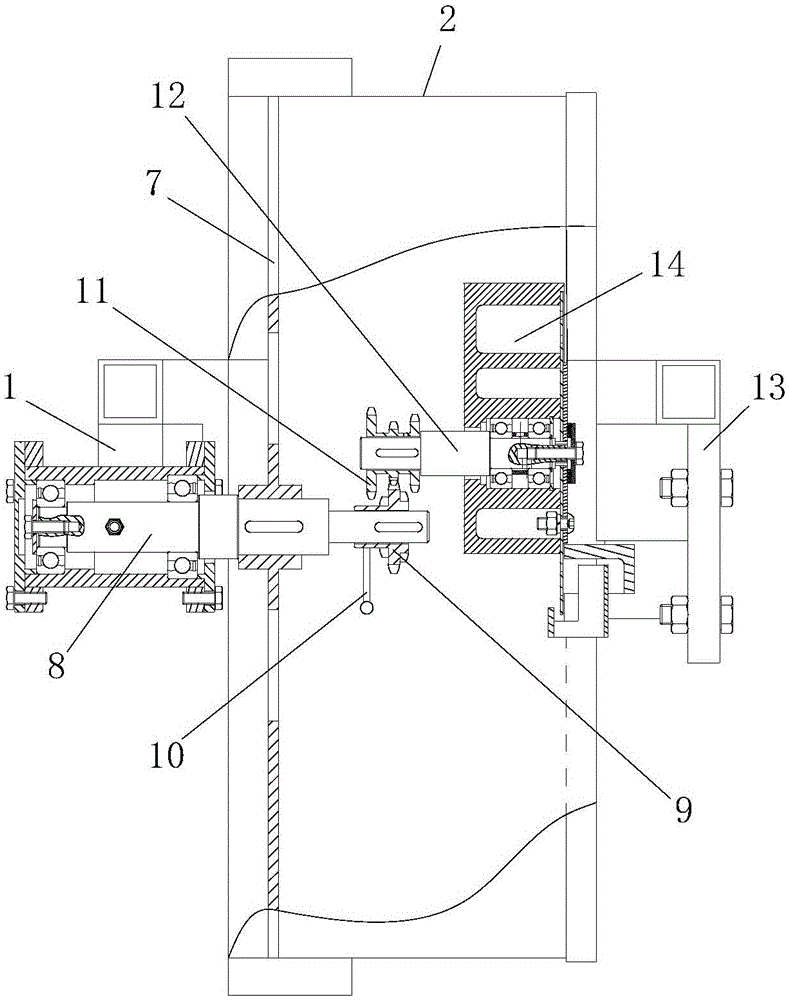

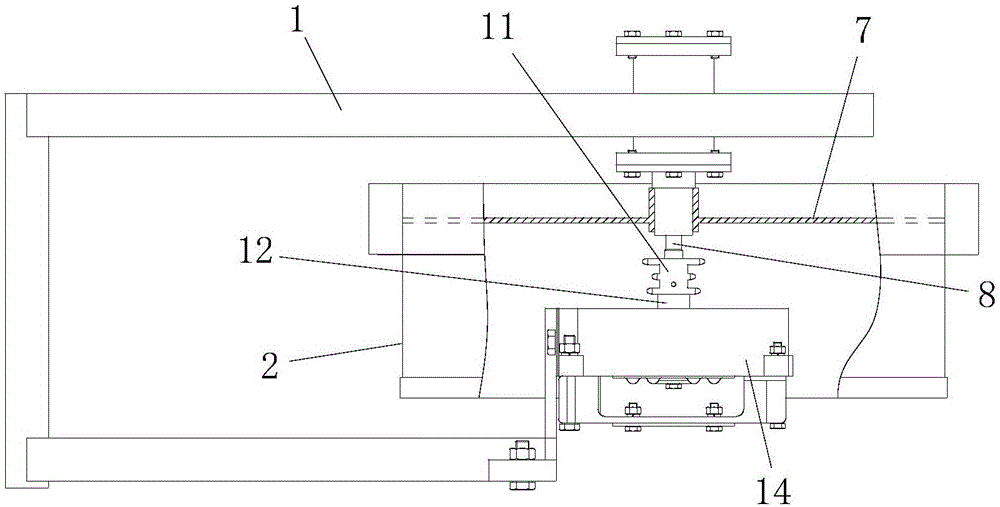

[0013] In this example, refer to figure 1 , figure 2 and image 3 , the adjustable hole spacing air-suction peanut hole-sowing wheel includes a traction frame 1, a roller body 2, a duckbill 3, a seed suction tray 4, a seed chamber 6, a support plate 7, a driving shaft 8, a bracket 13 and an air chamber 14, The roller body 2 is fixedly connected to the drive shaft 8 through the support plate 7, and one end of the drive shaft 8 is connected to the traction frame 1 through a bearing; The chamber 14 is attached, and the air chamber 14 is fixedly connected to the traction frame 1 through the bracket 13; the seed chamber 6 is installed on the side of the roller body 2, and the seed suction disc 4 is docked with the seed chamber 6; the duckbill 3 is installed on the roller body 2, and its Docking with the seed suction disc 4; the other end of the drive shaft 8 is equipped with a movable sliding gear 9, and the sliding gear 9 meshes with a transmission gear 11; the transmission gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com