Soil cutting and splitting device at front end of shield machine

A shield machine and soil technology, which is applied in earth drilling, mining equipment, tunnels, etc., can solve the problems of reducing excavation efficiency, tool wear, and instability of earth pressure balance, so as to improve cutting efficiency and prolong service life , to ensure the effect of earth pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

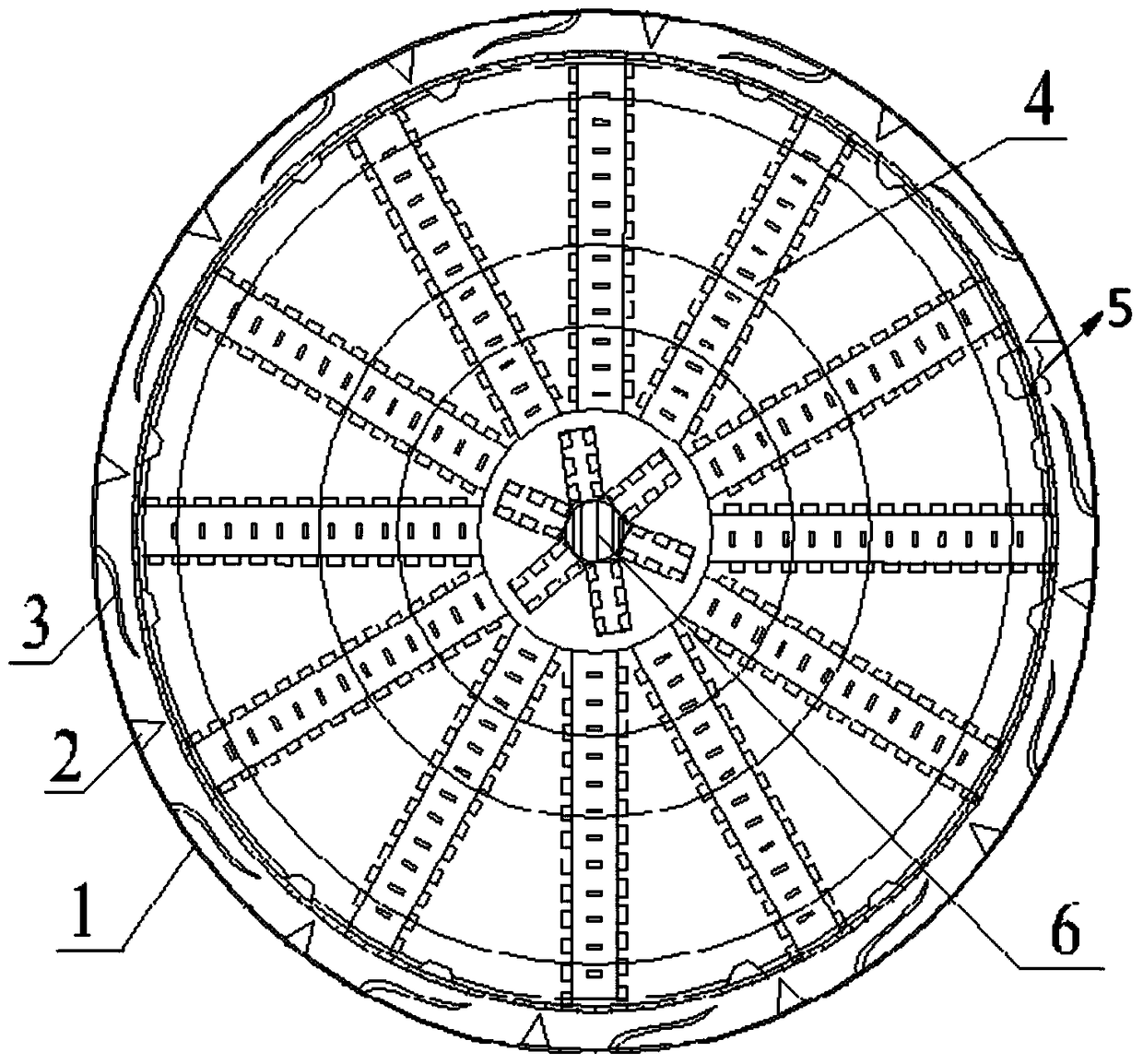

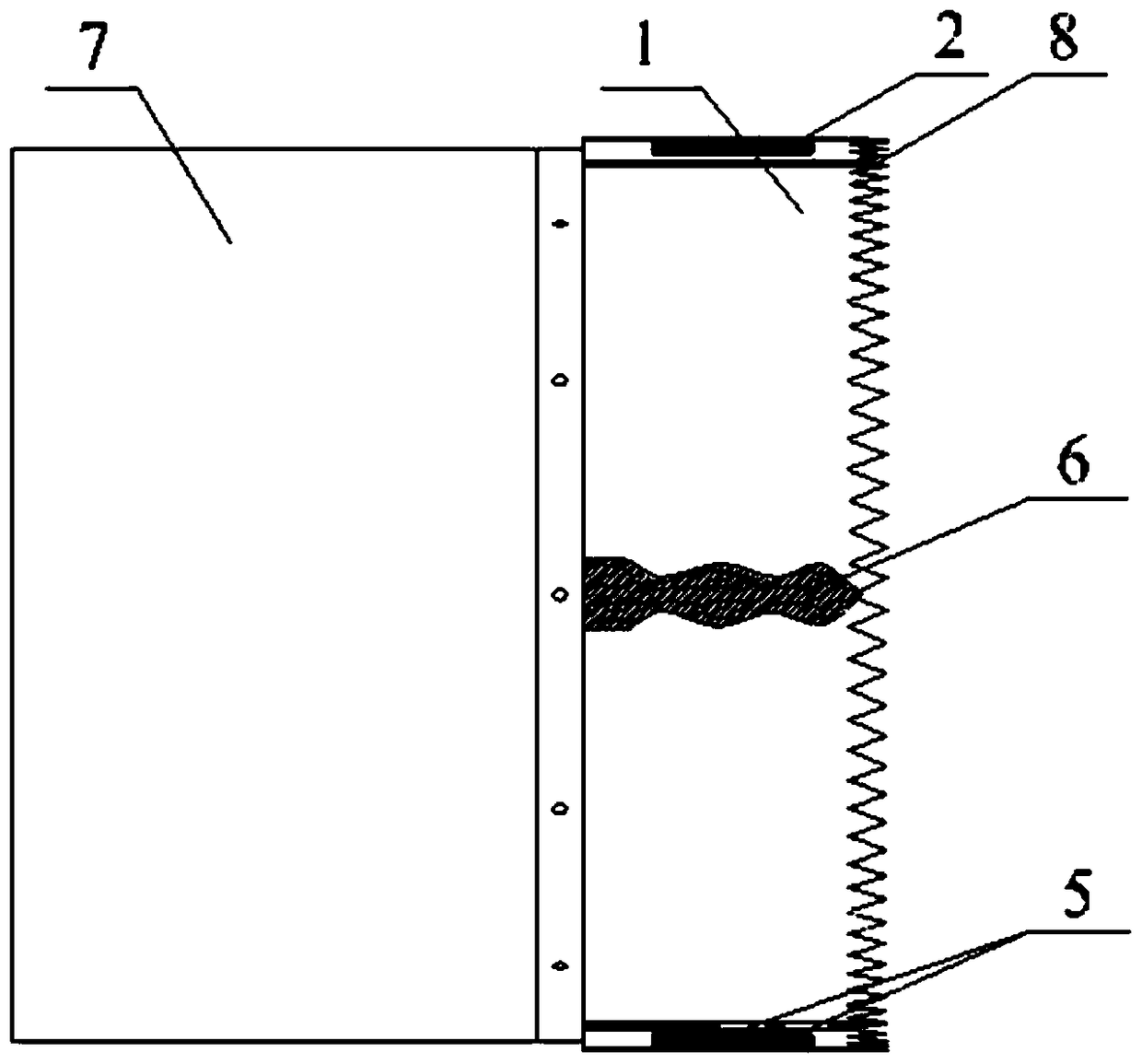

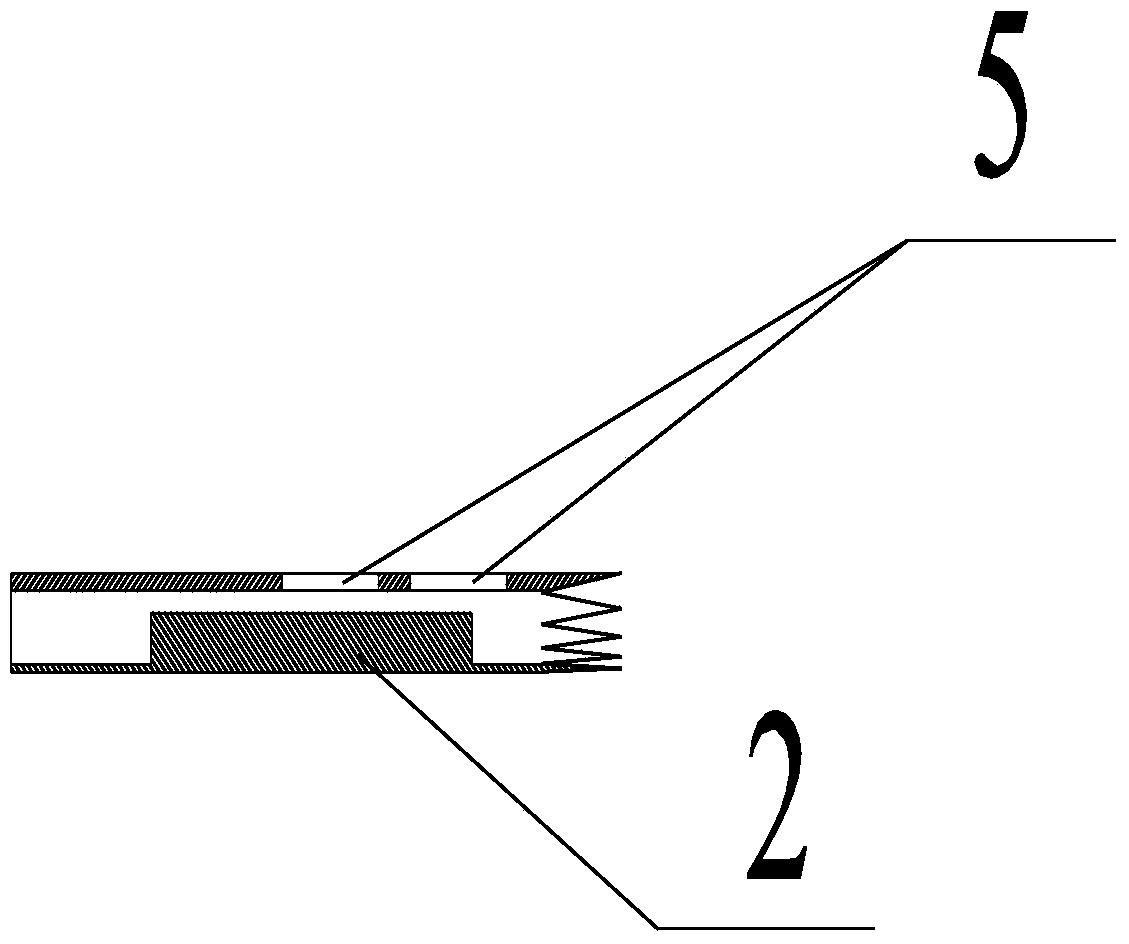

[0027] figure 1 It is a front view of the soil cutting and dividing device at the front end of the shield machine. The dividing device includes a cutter head 4 and a cutting cover 1 arranged around the circumference of the cutter head 4. The cutter head 4 includes a plurality of spokes arranged along the diameter of the cutter head 4. Each A plurality of cutters are arranged on the spokes, and a drill bit 6 is arranged at the center of the cutter head 4, and the drill bit 6 rotates together with the cutter head 4; the cutting cover 1 is annular, and the cutting cover 1 includes two layers of concentrically arranged circles, and the two circles The front part, that is, the part that is in contact with the soil first, is jagged, and the rear of the two circles is provided with 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com