A hemming device of a cot machine for hemming the sunroof of the cot

A technology of hemming device and leather casing machine, which is applied in decorative arts, pasting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are only preferred embodiments of the present invention, and are not intended to limit the protection scope of the present invention.

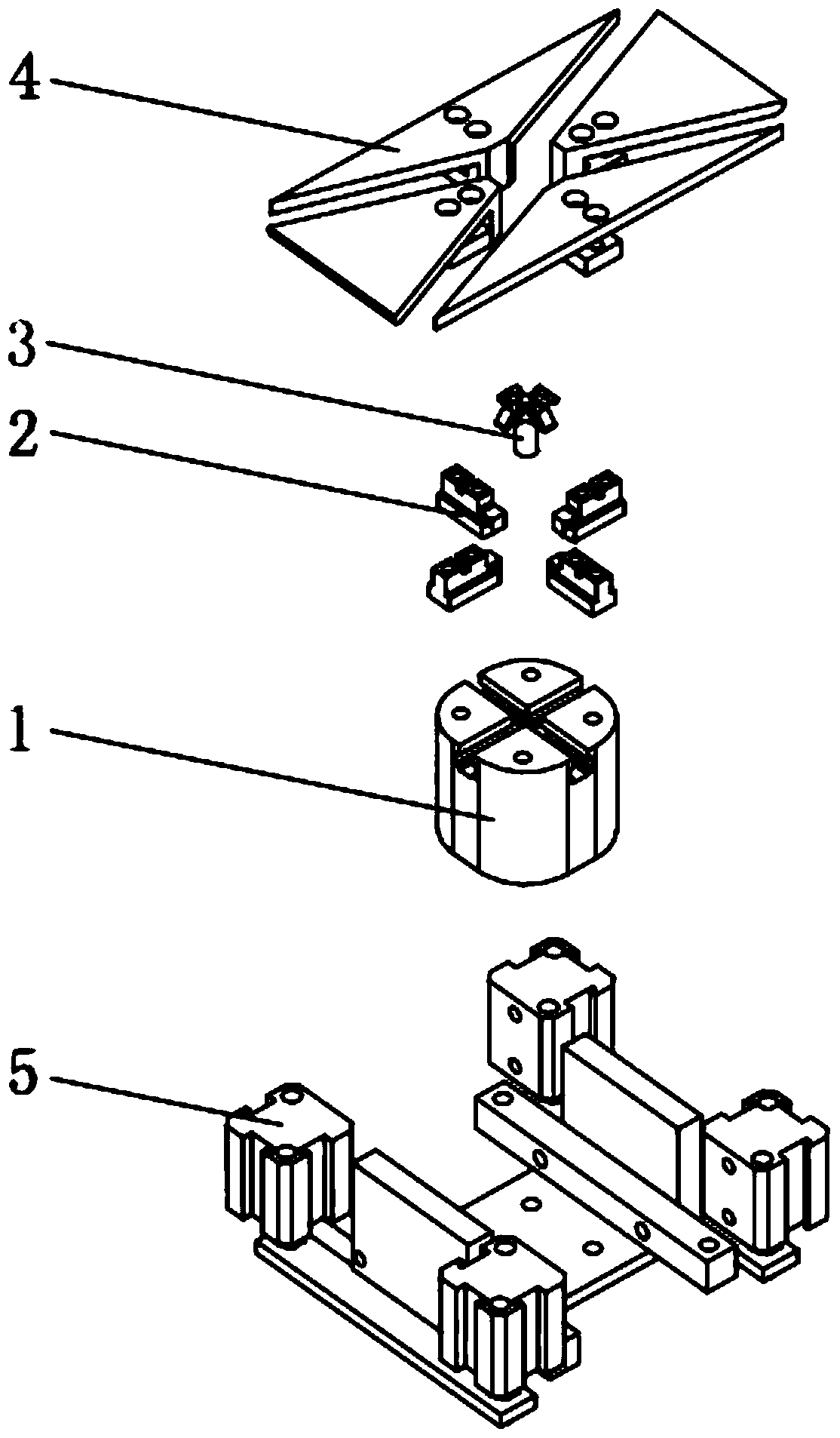

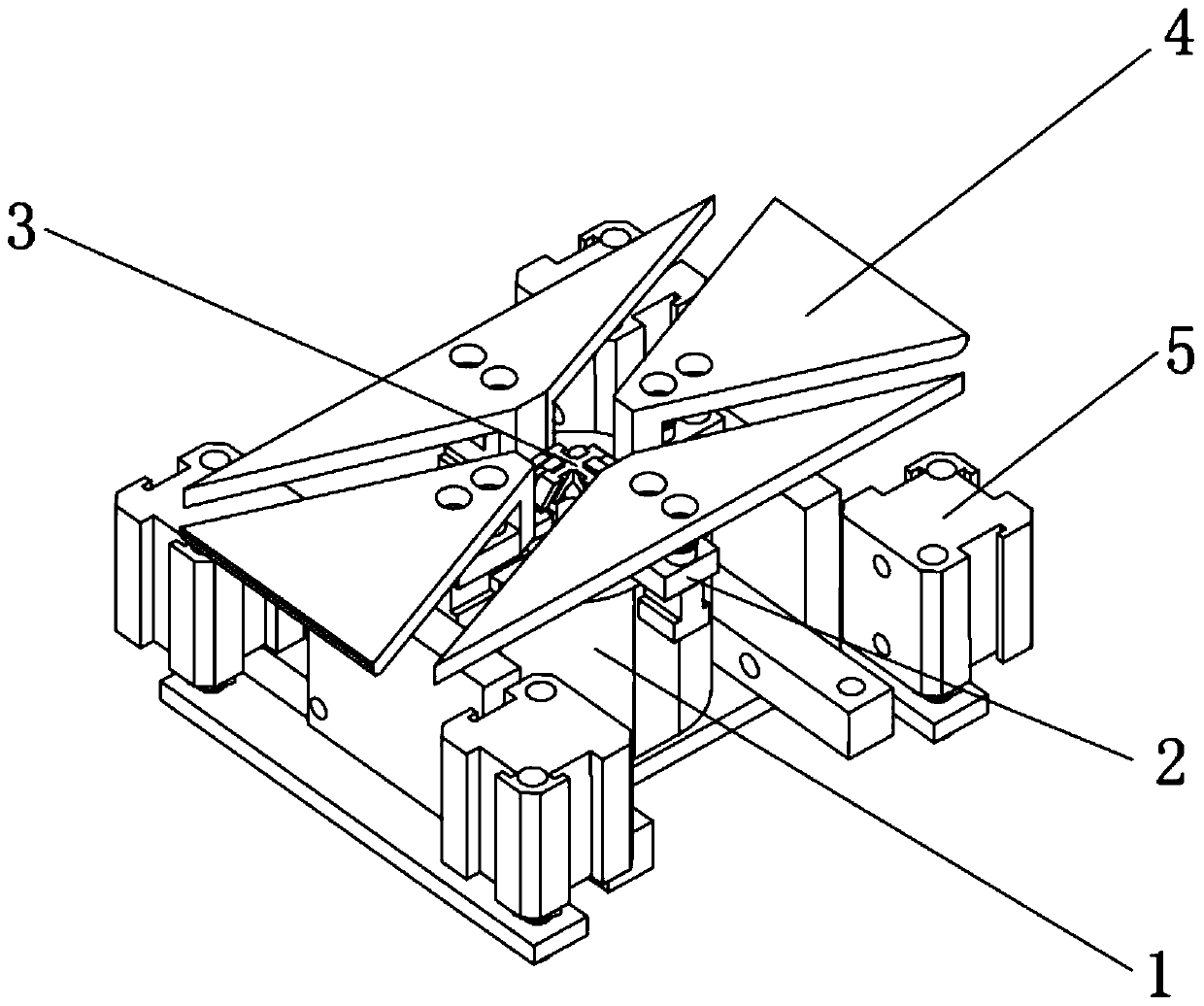

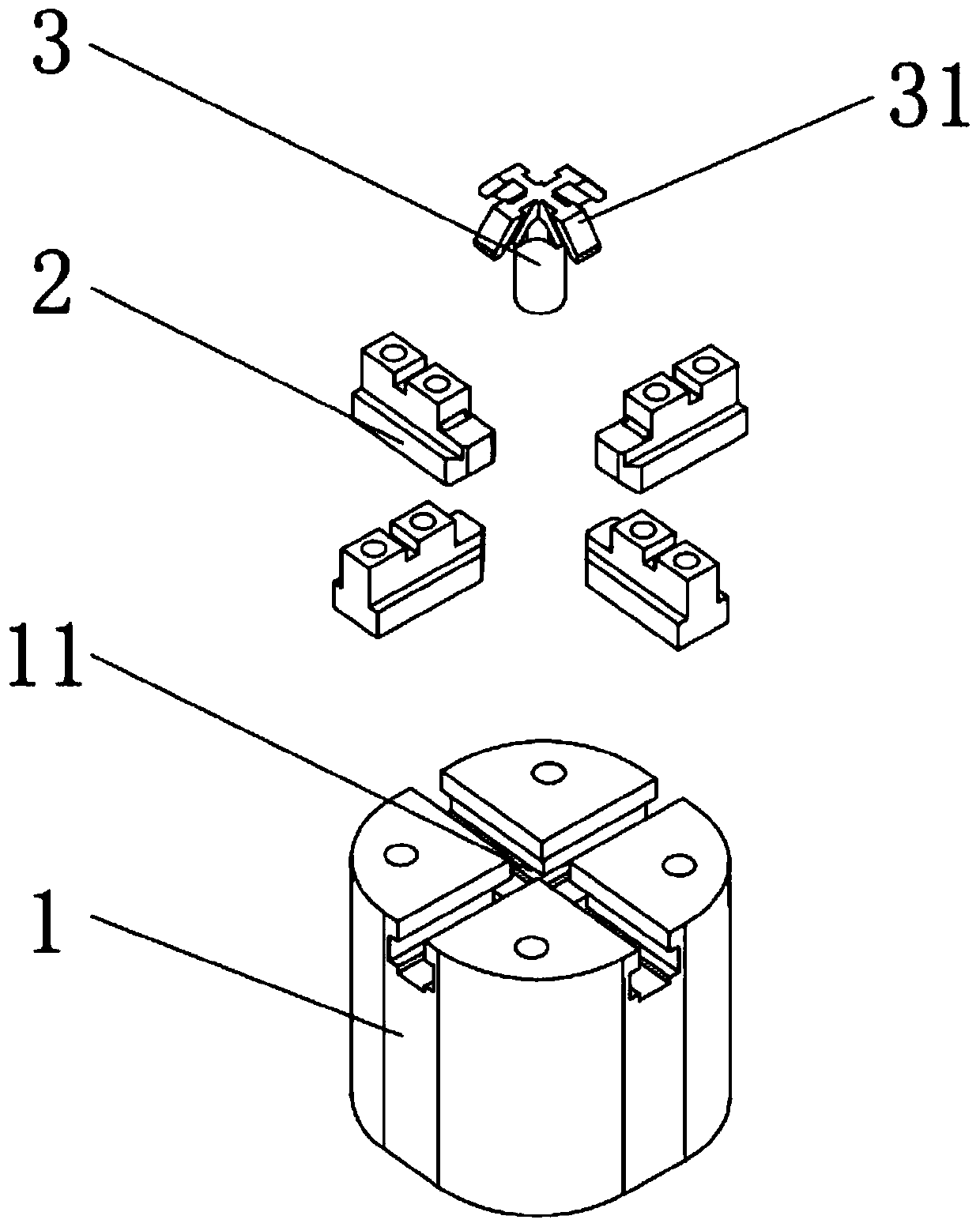

[0016] See Figure 1-2 As shown, the present invention discloses a hemming device of a cot machine for hemming the cot skylight part. The hemming device is installed on the lower side of the cot machine at the position of the cot skylight. The hemming device includes Seat 1, guide rail 2, lifting guide column 3 and pressure plate 4, mounting seat 1 top is provided with cross-shaped guide groove 11, is provided with guide rail groove outside guide groove 11 bottom, and guide rail groove is 4, in each The guide rail 2 is installed in a guide rail groove, and the guide rail 2 can slide in the guide groove. The upper end of the guide rail 2 is equipped with a pressure plate 4, and the front end of the guide rail 2 is provided with an inclined guide rail groove 21. The center of the mounting base 1 is provided with a through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com