Resin pool and 3d printer for light curing 3d printer

A 3D printer and photocuring technology, applied in the direction of additive processing, etc., can solve the problems of 3D printer production efficiency, photocuring accuracy reduction, semi-permeable film wrinkle deformation, etc., to improve user satisfaction, printing efficiency and cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

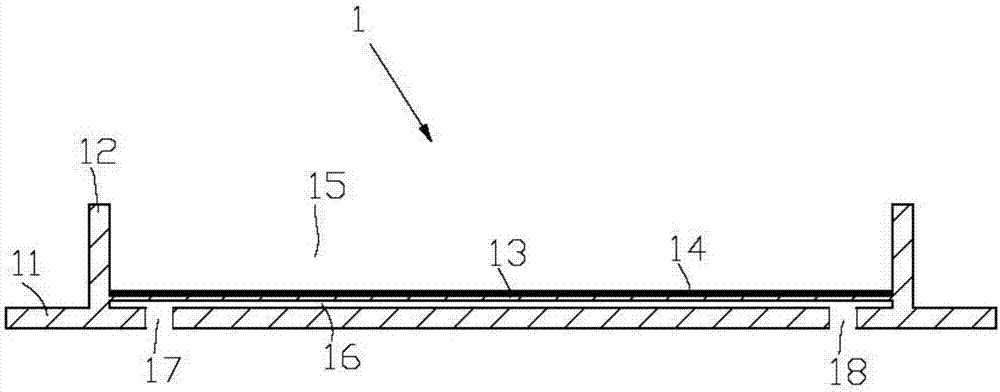

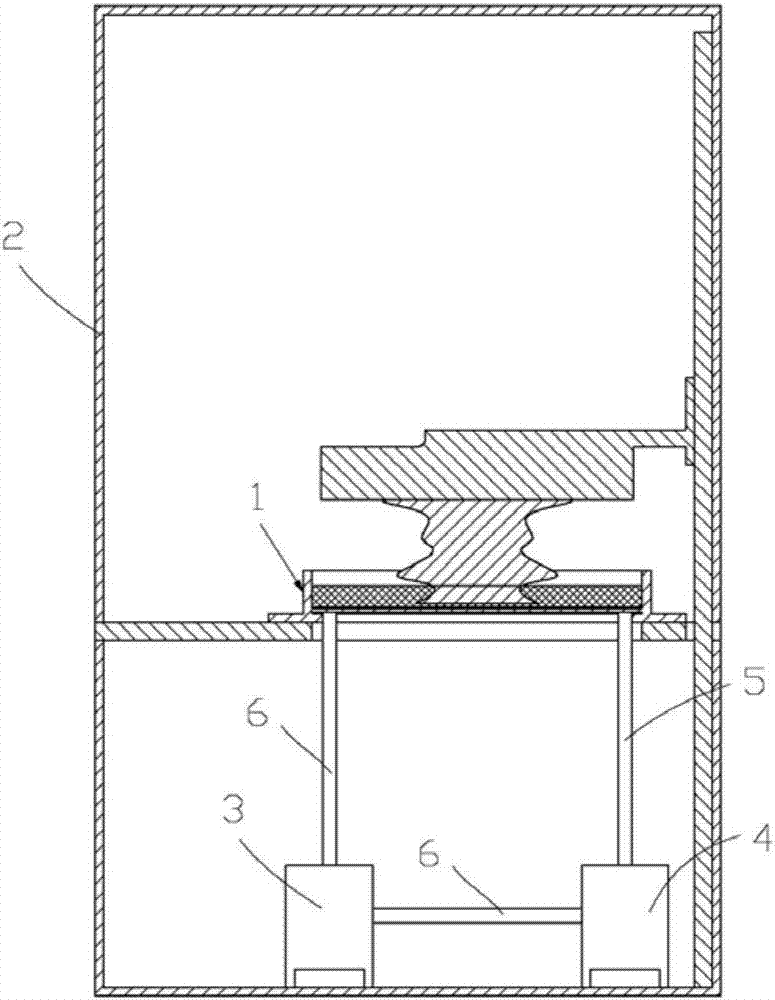

[0040] refer to figure 1, the present embodiment provides a resin pool 1 for photocuring 3D printers, which includes a bottom wall 11, which is arranged on the bottom wall 11 and forms a peripheral wall 12 of a first chamber 15 with the bottom wall 11, the bottom wall 11 And surrounding wall 12 can be split type design, also can integrally form. A first hole 17 and a second hole 18 are defined on the bottom wall 11 . The first hole 17 and the second hole 18 are located on the left and right sides of the bottom wall 11 . A support plate 13 is also provided in the first chamber 15 . The periphery of the support plate 13 is fixedly connected with the peripheral wall 11 , and a second chamber 16 is formed between the support plate 13 and the bottom wall 11 . The second chamber 16 is located inside said first chamber 15 . The support plate 13 is a separate component, and can also be integrally formed with the surrounding wall 11 . The support plate 13 is covered with a semi-pe...

Embodiment 2

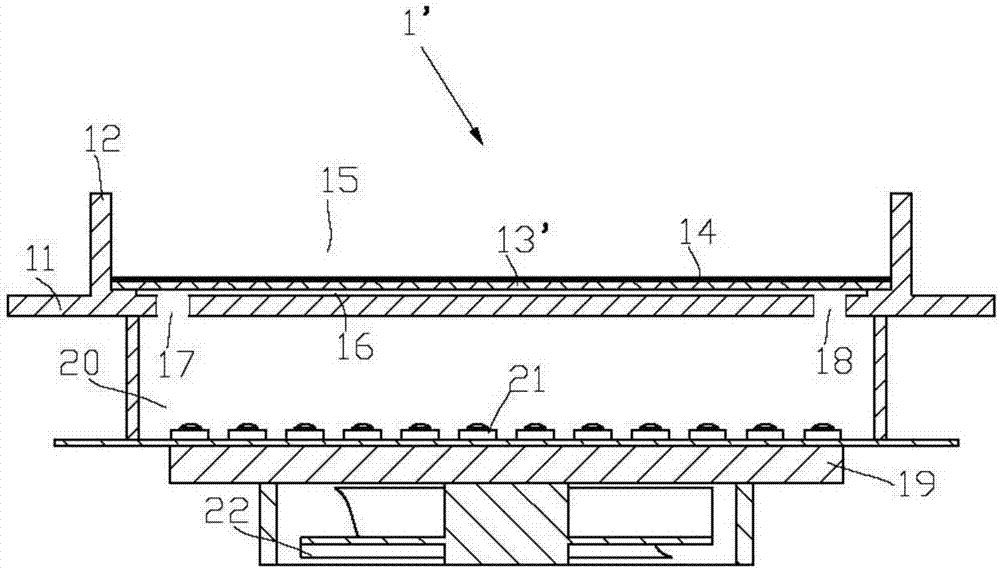

[0044] refer to image 3 , this embodiment provides another resin pool 1' for a light-curing 3D printer, which is similar in structure to the resin pool 1 in Embodiment 1, except that the support plate 13 is replaced by an LCD display unit 13'. Therefore, this resin pool is especially suitable for 3D printers based on LCD light curing 3D printer technology. In addition, a cooling plate 19 is also provided on the lower part of the bottom wall 11 . The heat dissipation plate 19 and the bottom wall 11 form a third chamber 20 . The light source 21 is arranged on the cooling plate 19 and is located in the third chamber 20, and the light beam emitted by it can directly shine on the LCD display unit 13' through the transparent bottom wall 11, and then the light is irradiated in the third chamber according to the image displayed by the LCD display unit. A liquid photosensitive resin in a chamber 15 is solidified into a corresponding shape. In order to better solve the heat dissipat...

Embodiment 3

[0048] refer to Figure 5 and Figure 6 , this embodiment provides another resin pool 1" for photocuring 3D printers, which basically adopts the structure of the resin pool provided in Embodiment 2, except that the cooling plate 19 has a fourth chamber 23, and has a third hole 24 and a fourth hole 25 communicating with the fourth chamber 23. It should be understood that the fourth chamber 23 can be the self-structure of the cooling plate 19, or it can be formed by setting other parts It is enclosed with the heat dissipation plate 19. The upper part of the heat dissipation plate 19 is equipped with a heat dissipation fan.

[0049] During use, the water inlet pipe 6 of the liquid container 4 can be connected with the second hole 18 first, the outlet pipe 5 of the liquid container 4 can be connected with the fourth hole 25, and then the first hole 17 and the third hole 24 can be communicated with the connecting pipe 7 . A pump 3 and a radiator 8 are sequentially arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com