Vehicle spoke roundness trimming device

A technology for automobile wheels and wheel spokes is applied in the field of rounding devices for automobile wheel spokes, which can solve problems such as increasing production costs and prolonging product manufacturing time, and achieves the effects of improving quality, reducing production costs and reducing out-of-roundness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

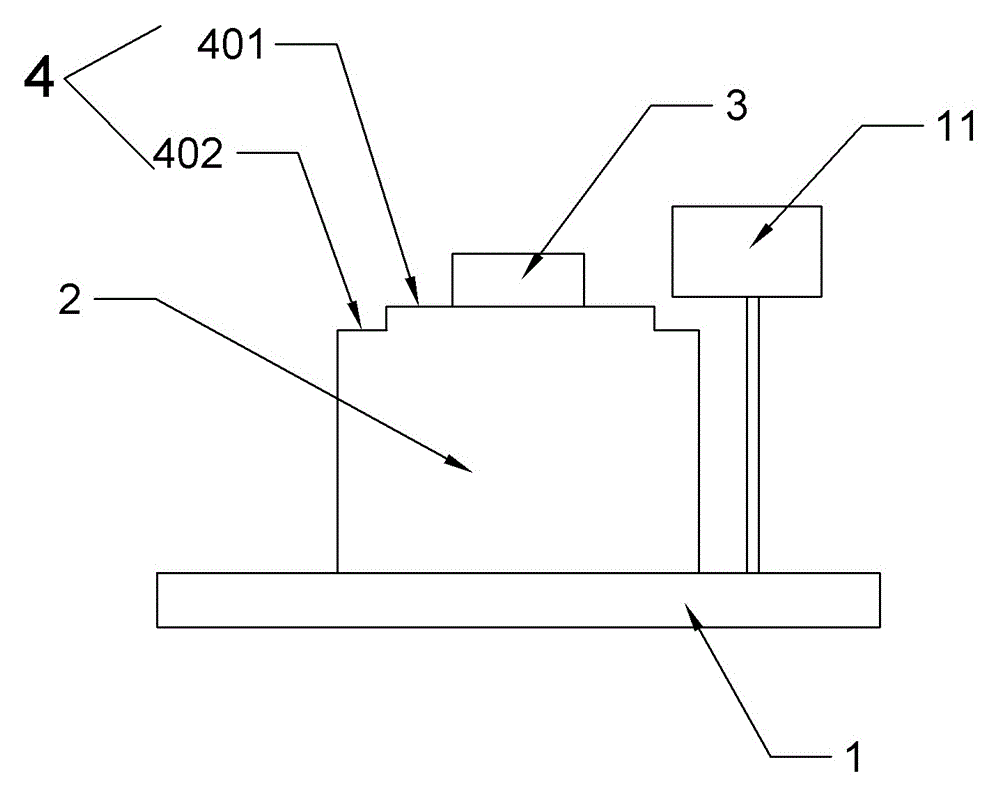

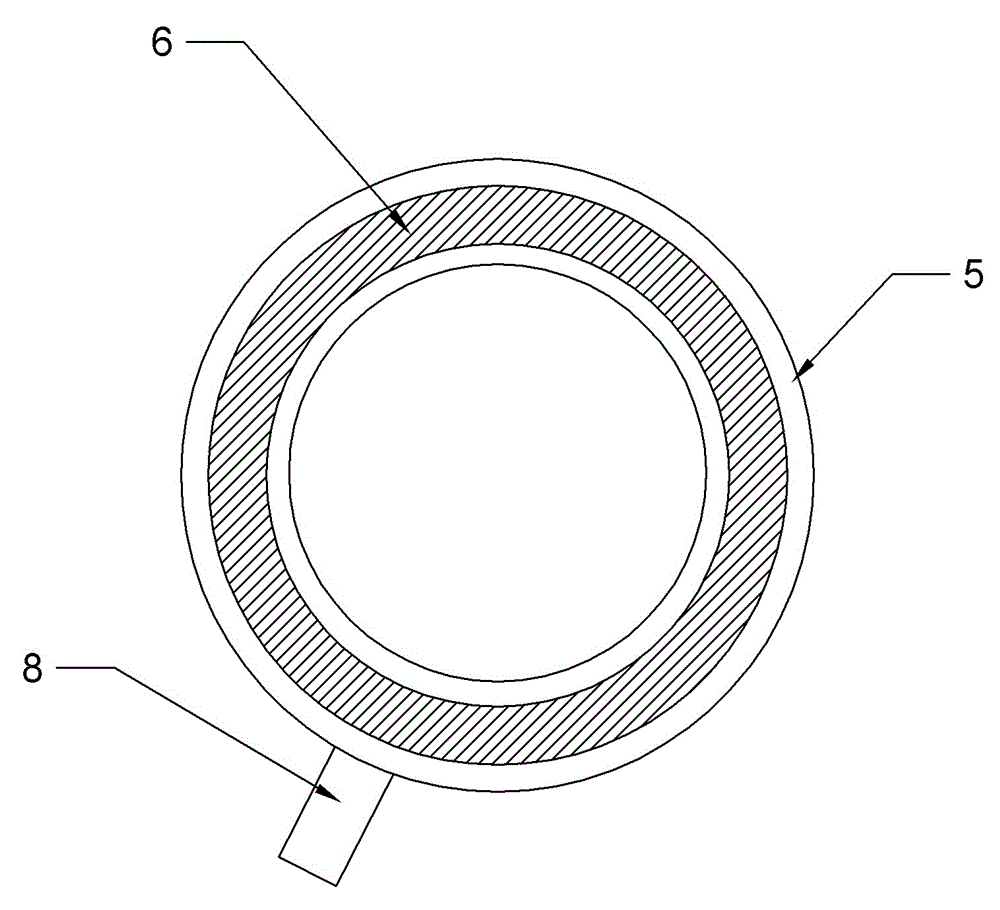

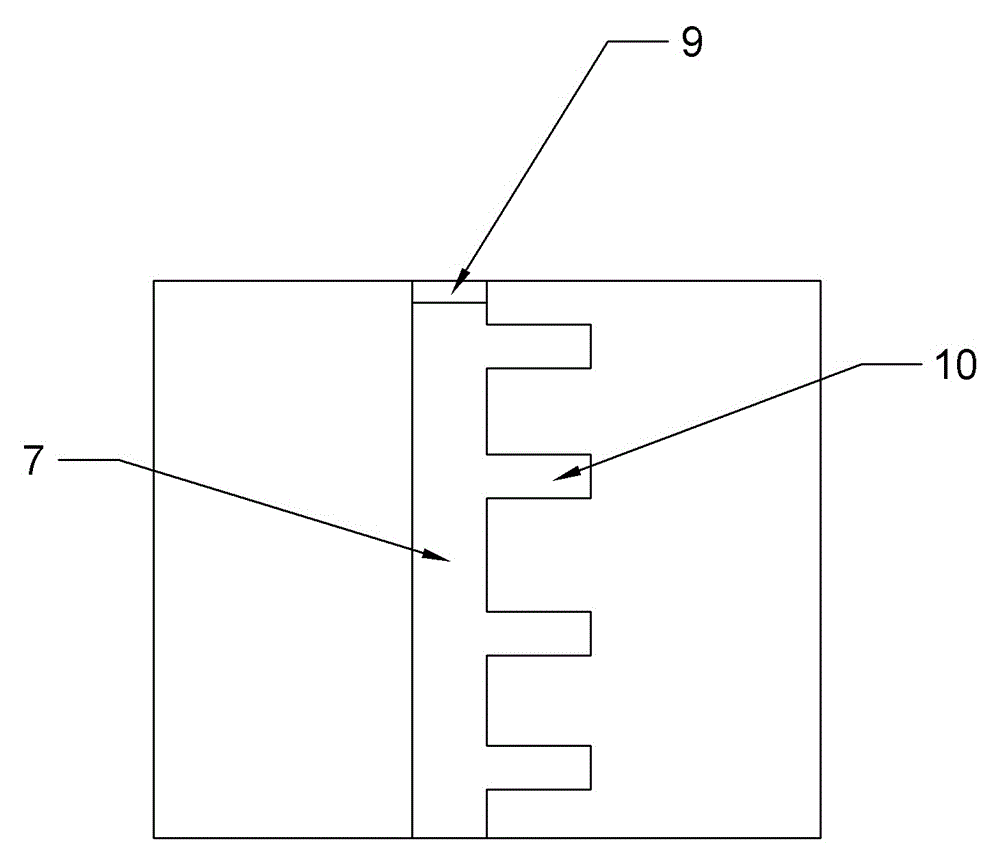

[0019] like figure 1 , figure 2 and image 3 As shown, the full-circle device of the automobile wheel spoke includes a base 1, a mounting base 2 and a mandrel 3, the base 1 is parallel to the horizontal plane of the ground, and the base 1 is provided with bolt holes, and the screws pass through the bolt holes to connect the base 1 is fixed on a horizontal tabletop. The mounting seat 2 is cylindrical, and the mounting seat 2 and the base 1 are integrally formed to ensure a horizontal reference, so that the spokes are on a horizontal plane. The top of the mounting seat 2 is the mounting surface 4, the mounting surface 4 is matched with the arc surface of the spoke, including a fixed surface 401 raised in the middle and a horizontal surface 402 corresponding to the edge of the spoke, and the spoke undercut is installed on the mounting surface 4, achieve axial positioning. A mandrel 3 is provided at the center of the mounting surface 4, and the mandrel 3 is a cylindrical prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com