garlic upright planter

A seeder and garlic technology, applied in the field of agricultural machinery, can solve the problems of unstable control of the direction of the scales and buds, the success rate of erection cannot meet the agronomic requirements, and the problems such as the failure to solve the erection of garlic in the soil, so as to achieve directional planting, uniform sowing and missed sowing. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order for those skilled in the art to better understand the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the following is only exemplary and does not limit the protection scope of the present invention.

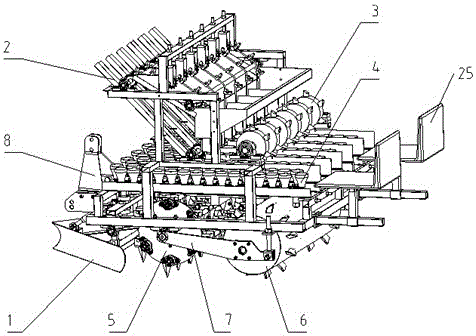

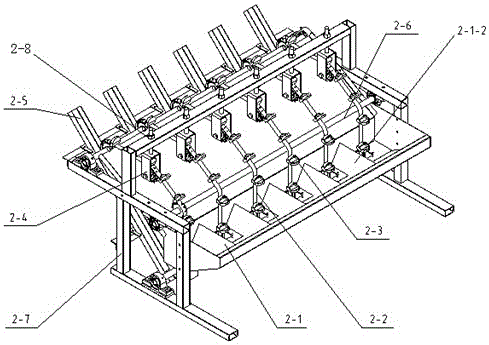

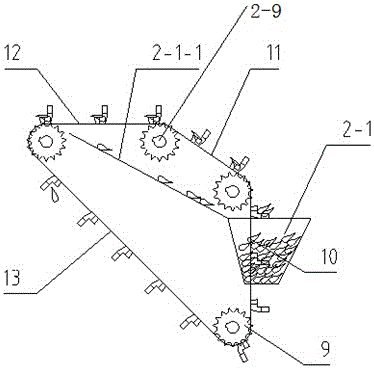

[0048] as attached figure 1 and Figure 19 Described, a kind of upright planting planter for garlic, comprises: frame 8, seed picking device 2, upright planting device 5, leveling device 1, scale bud direction control device 4, quantitative water injection device 3, transmission device and ground wheel device6. The frame 8 is the carrier of the whole planter, all devices are installed on the frame 8, and the artificial auxiliary seat 25 is installed at the rear of the frame 8; The upright planting device 5 is located below the frame 8 and is located at the front of the entire planter; the leveling device 1 is located under the front of the frame 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com