An orchard weeder

A technology for weeding machines and orchards, applied in the fields of soil preparation machinery, agricultural machinery and implements, applications, etc., can solve the problems of unsuitable weeding operations, unpopularity, and impracticality, and achieves professional agricultural machinery technical knowledge requirements are low, and the lifting mechanism Simple and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

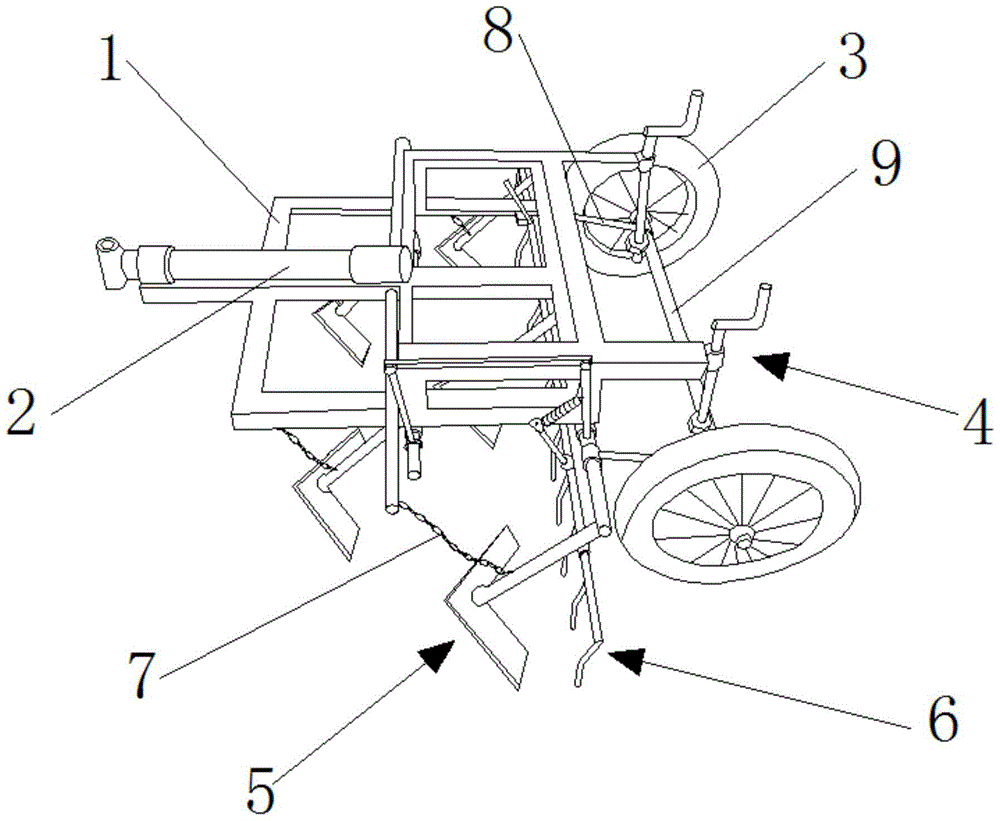

[0036] Such as figure 1 As shown, the present invention comprises a vehicle frame 1 and a drawbar 2 fixedly installed on the vehicle frame 1, and the bottom of the vehicle frame 1 is rotatably equipped with a weeding device 5, and the weeding device 5 is used for the weeding machine to During the front driving process, the weeding device is broken and weeded, and the rear part of the weeding device 5 is rotated with a rake device 6, and the rake device 6 is used to collect the weeds buried in the soil after the weeding device 5 weeds. The weeding device 5 is rotatably connected to one end of the first connecting rod 8, and the other end of the first connecting rod 8 is rotatably connected to a wheel shaft 9 positioned at the rear of the vehicle frame 1, and both ends of the wheel shaft 9 are rotatably mounted. Deep wheel 3, a lifting mechanism 4 for adjusting the height of the vehicle frame 1 is installed between the vehicle frame 1 and the wheel shaft 9.

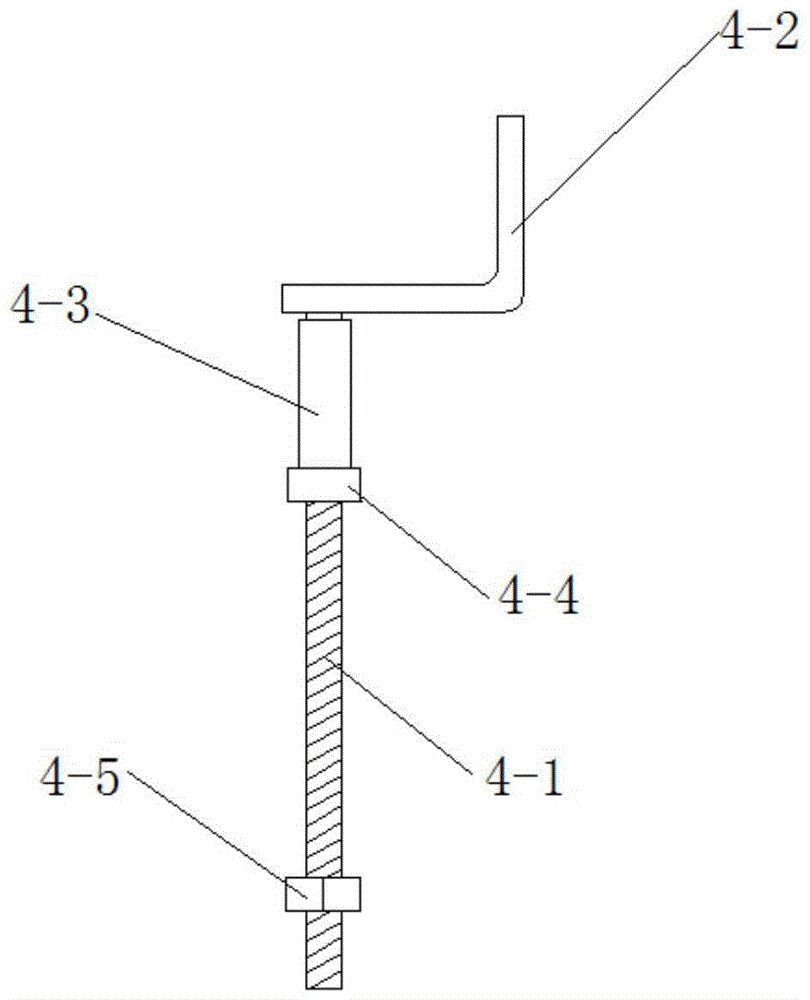

[0037] Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com