Fixing part for refrigerator fin evaporator and refrigerator provided with fixing part

A technology of finned evaporators and fixing parts, which is applied in the field of refrigerator structure design, can solve problems such as difficult operation, low disassembly efficiency, and unsuitable realization, and achieves the effects of simple disassembly operation, time-saving operation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

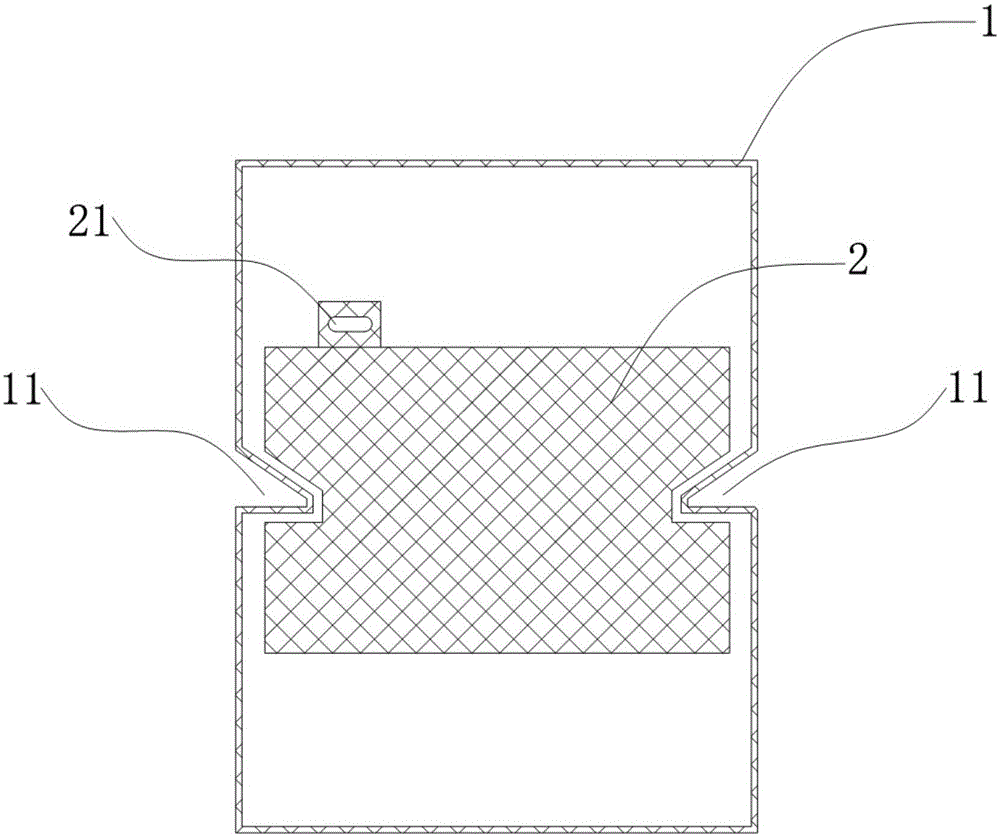

[0036] Such as figure 1 As shown, in the first prior art, the finned evaporator 2 is integrally fixed on the tank 1 by two bosses 11 and one screw. First push the finned evaporator 2 into the boss 11 of the tank 1 so as to limit the upper and lower positions; then use a screw to fix the front and rear positions at the screw fixing hole 21. Its disadvantages: screw fixing installation and disassembly efficiency is low, due to the large volume and thickness of the fins, the hand cannot go deep, and employees need a long gun head with screws to fix it, making the operation difficult.

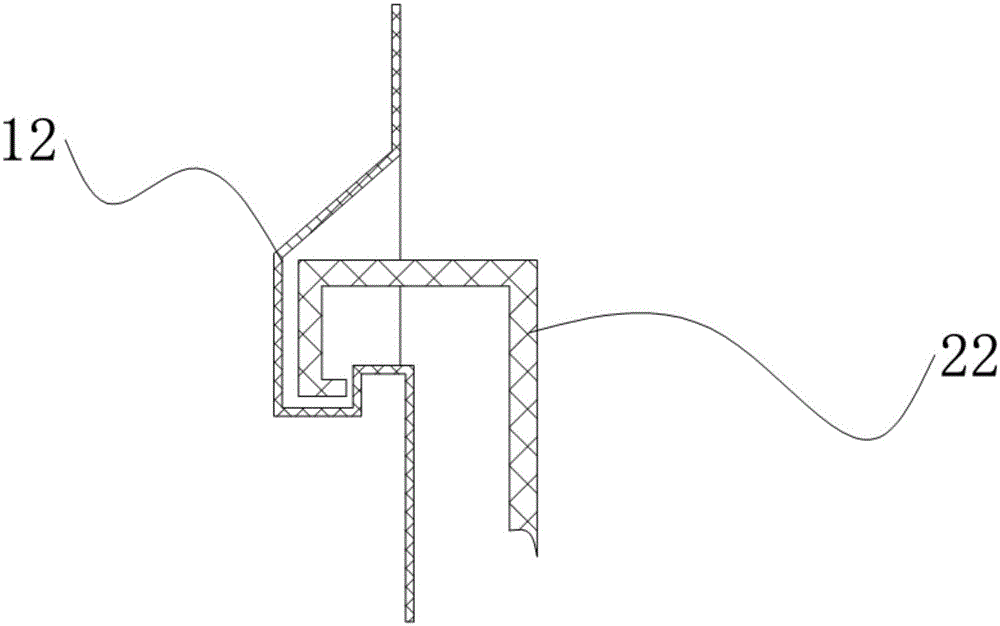

[0037] Such as figure 2 As shown, the second prior art is based on the first prior art, changing the screw fixing to the hook 22 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com