A lime digestion dosing and feeding device

A lime digestion, dosing and feeding device technology, applied in the field of water treatment, can solve the problems of large lime dust, uneven feeding, no continuity, etc., and achieve the effects of saving labor, smooth flow, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed structure of the present invention will be further described below in conjunction with the drawings and specific embodiments.

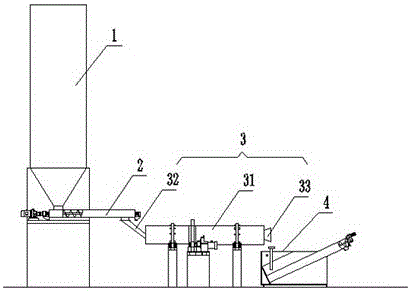

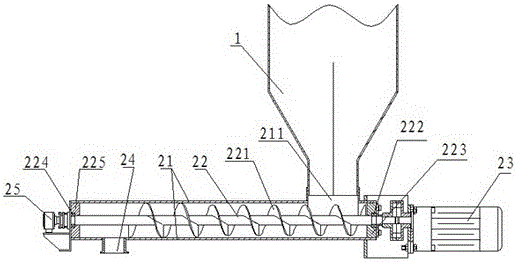

[0017] Such as figure 1 As shown, a lime digestion dosing and feeding device includes: a lime feeding device 2, a lime digestion unit 3, a lime milk separation unit 4 and a lime dosing unit; wherein the lime digestion unit 3 includes a cylinder 31, a cylinder 31 There is a material inlet 32 and a material outlet 33 on the top, and the inside of the cylinder 31 is divided into successively from the material inlet 32 to the material outlet 33: a buffer zone, a homogeneous area, a milk slag separation area, and a slag removal area; The quicklime is digested into a lime-milk-sand-water mixture after passing through the lime digestion unit 3, and the lime-milk-sand-water mixture flows out from the discharge port 33; the lime-milk separation unit 4 separates the lime-milk-sand-water mixture flowing in from the discharge port 33 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com