Bucket structure and bucket elevator

A technology of bucket elevator and hopper, which is applied in the field of material lifting equipment, can solve the problem of low discharge rate and achieve the effect of high discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

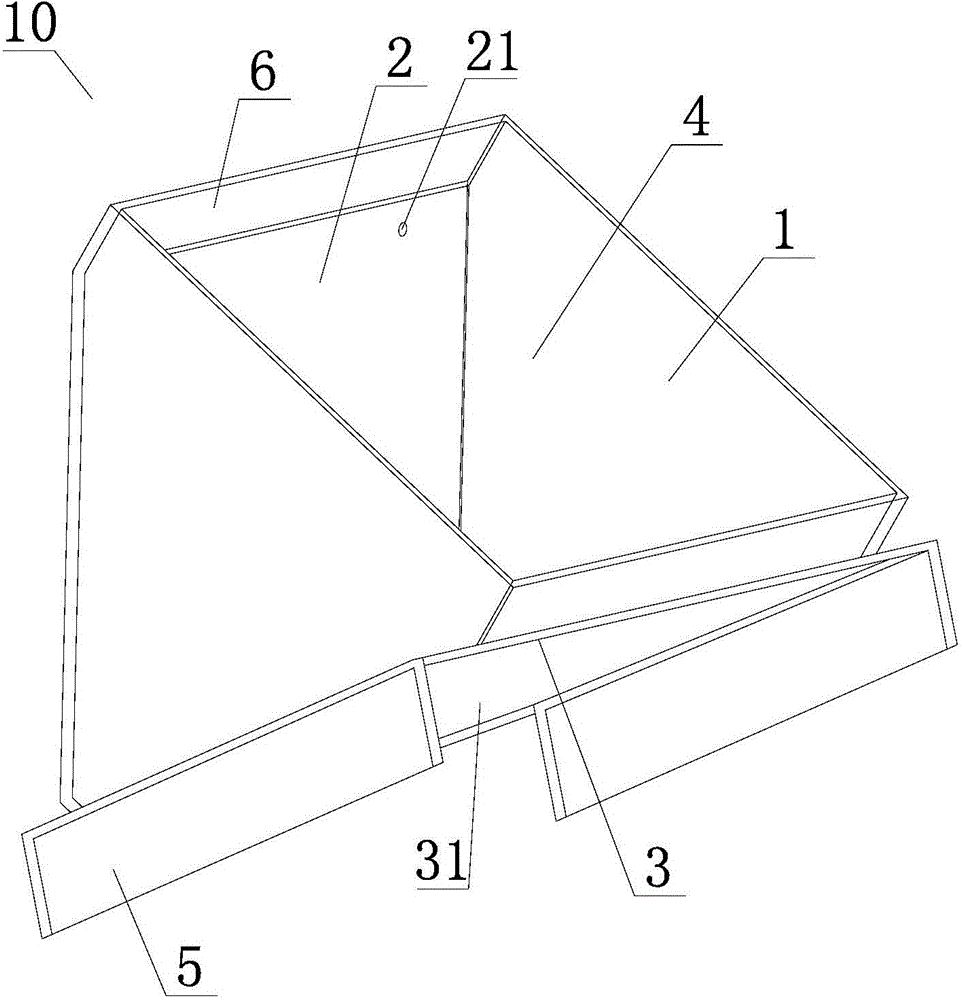

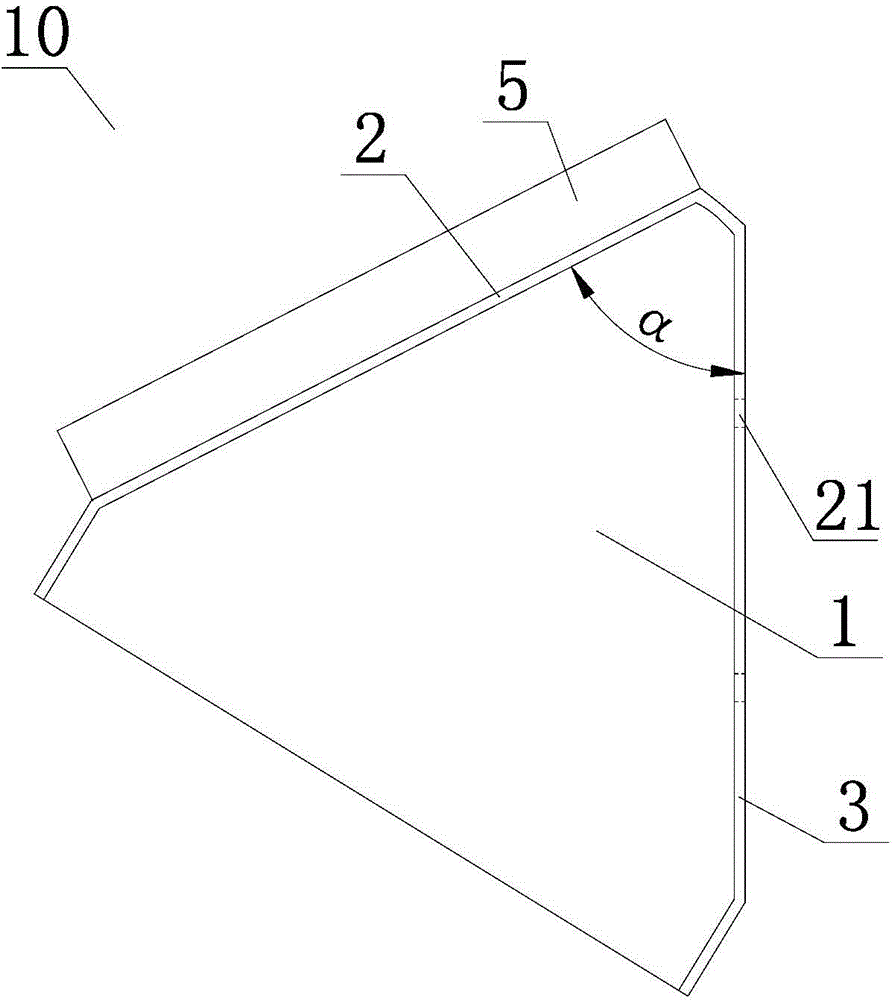

[0043] Further, in order to realize the function of the above-mentioned guiding structure, such as figure 1 and figure 2 As shown, the present invention also provides the following embodiment: the guide structure includes a baffle plate 5, the number of the baffle plate 5 is two, and the two baffle plates 5 are arranged oppositely, and the first groove is formed on the guide plane 31 (in the figure not marked). Wherein, the baffles 5 are two independent parts, and the two baffles 5 protrude from the upper surface of the guiding plane 31 , and the two baffles 5 and the guiding plane 31 jointly enclose the above-mentioned first groove. The first groove is a guide groove, and the first groove can be a guide for materials falling on it, and guide the materials to a set area.

[0044] Certainly, the guiding structure is not limited to the configuration of this embodiment, and in another embodiment, the guiding structure includes a second groove disposed on the guiding plane 31 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com