A fully automated garbage incineration device

A fully automated technology for garbage incineration, applied in garbage receptacles, incinerators, combustion methods, etc., can solve the problems of easy falling out of garbage, affecting the surrounding environment, and serious odor emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

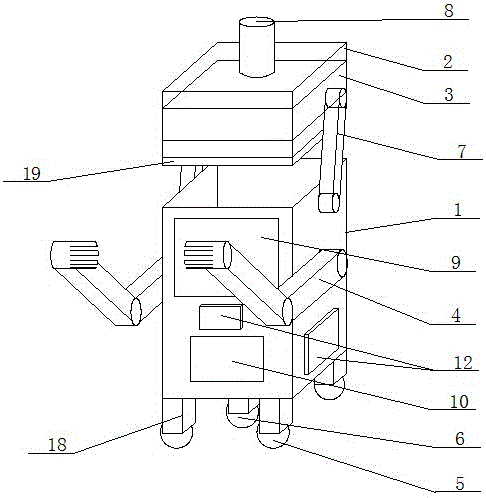

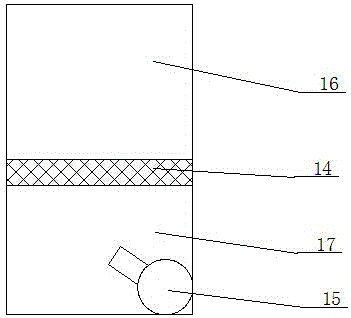

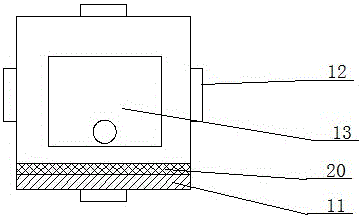

[0017] Below in conjunction with accompanying drawing, the present invention will be further described.

[0018] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a body 1, a top cover 2, a flue gas purification system 3, a manipulator 4, a roller 5, a universal wheel 6, a rotating lifting arm 7, an air outlet channel 8, and a dustbin Identification system 9, control panel 10, main circuit board 11, displacement sensor 12, bottom door 13, combustion plate 14, burner 15, garbage bin 16, incineration ash into bin 17; the upper part of the body 1 is passed through the rotating lifting arm 7 is connected with the top cover 2, the inside of the top cover 2 is equipped with a flue gas purification system 3, and the top cover 2 is provided with an air outlet channel 8, the two sides of the body 1 are screwed with a manipulator 4, and the bottom of the body 1 is provided with several Roller 5, and the bottom of body 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com