Folding propeller with limiting structures

A technology of limiting structure and blade, applied in the field of aviation devices, can solve the problems of easy horizontal movement of the blade, difficult to deploy and start the blade, affecting storage and transportation, etc., so as to improve the flight safety factor, reduce the risk of take-off failure, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

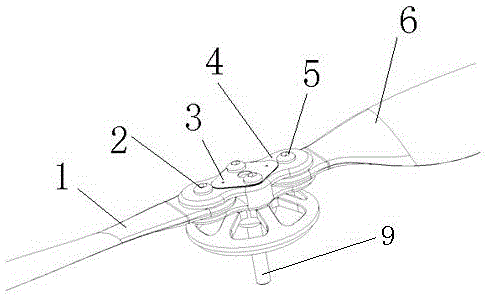

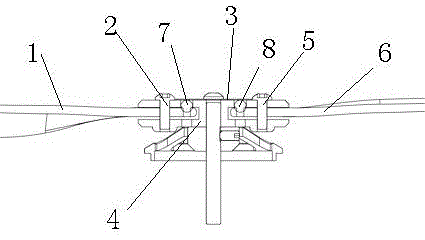

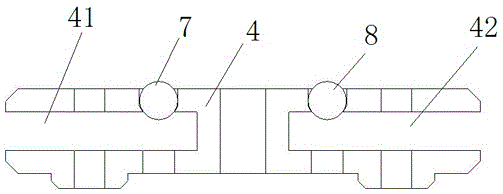

[0015] The present invention will be further described in detail in conjunction with the accompanying drawings. Each mark in the accompanying drawings is: Each mark in the accompanying drawings is: 1: left blade; 2: left vertical shaft; 3: elastic steel sheet; 4: oar clip; 41: Left U-shaped opening; 42: Right U-shaped opening; 43: Left long gap; 44: Right long gap; 5: Right vertical shaft; 6: Right propeller; 61: Positioning slot one; 62: Positioning slot two; 63: Positioning groove three; 601: positioning pit one; 602: positioning pit two; 603: positioning pit three; 7: left positioning bead; 8: right positioning bead; 9: power shaft; 10: left positioning slider; 101 : Left positioning slider handle;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com