Slip casting mechanism

A technology of grouting molding and molding cavity, which is used in ceramic molding machines, die-casting molds, manufacturing tools, etc., can solve the problems of large gaps, leakage, and poor ceramic molding effect at the junction of punches and punches. leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

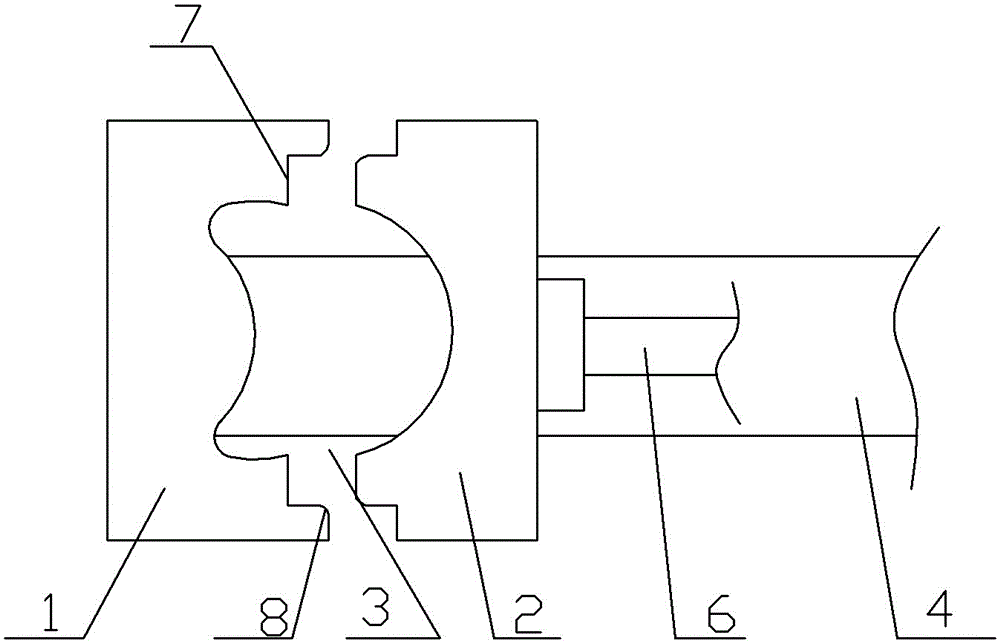

[0013] The present invention is described in further detail below by specific embodiments:

[0014] The reference signs in the accompanying drawings of the description include: punch 1, die 2, mud forming cavity 3, guide groove 4, roller 5, cylinder output shaft 6, right-angle fold line structure 7, guide angle 8.

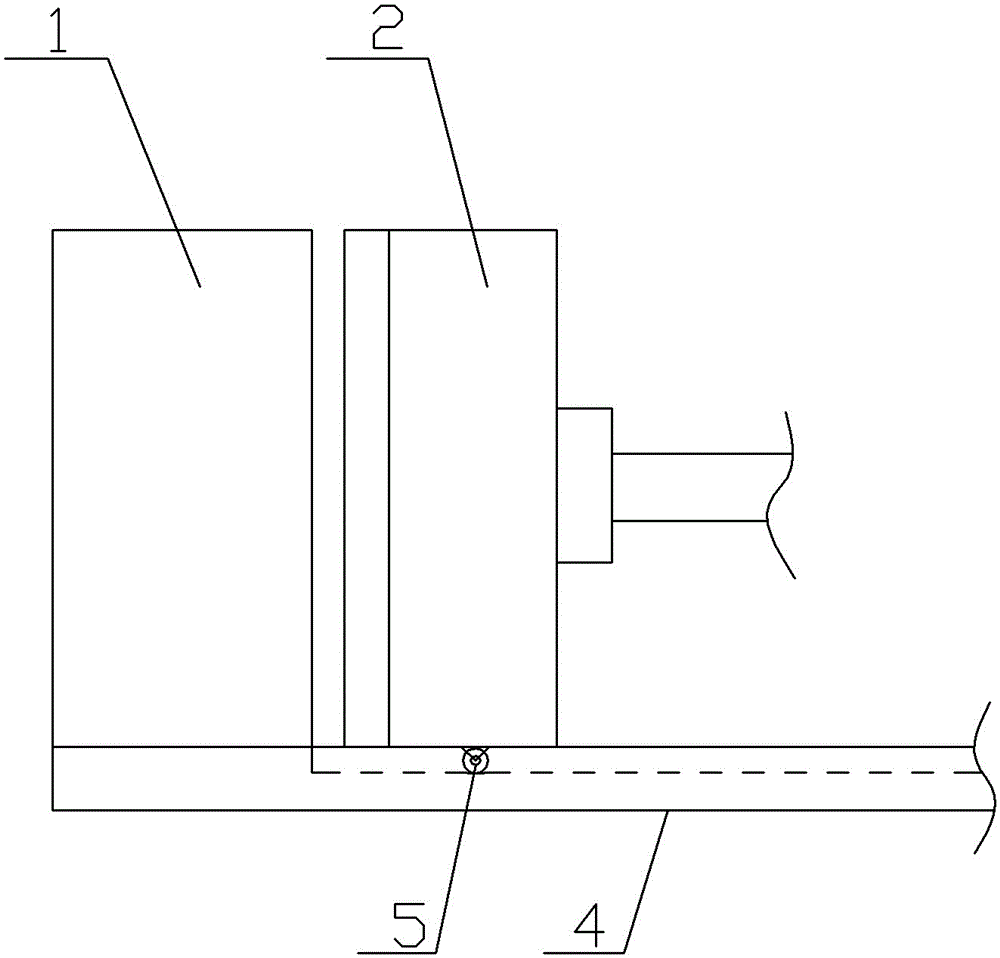

[0015] The embodiment grouting molding mechanism is basically as attached figure 1 shown:

[0016] The grouting molding mechanism includes a punch 1 and a die 2.

[0017] The middle part of the male mold 1 is a protrusion, and the middle part of the concave mold 2 is a groove. After the convex surface is matched with the concave mold 2, a mud molding cavity 3 with the same shape and size as the target ceramic product is formed between the protrusion and the groove. A pipeline is opened on the punch 1, and the pipeline communicates with the mud forming cavity 3, and the pipeline is externally connected with a mud pump.

[0018] like figure 1 As shown, the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com