Knife for removing lateral bones of hairtail

A technology for removing knives and hairtails, applied in the field of kitchen utensils, can solve the troublesome and inconvenient problems of removing side thorns, achieve the effect of convenient life, fast and convenient operation, and solve troubles and inconveniences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

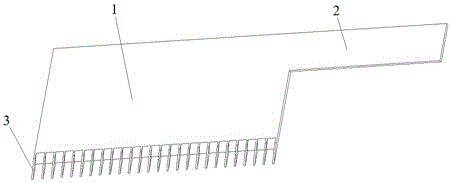

[0016] like figure 1 shown. A hairtail side spine removal knife, comprising a knife body 1, a knife handle 2, and comb teeth 3, a plurality of comb teeth 3 are arranged at the lower end of the knife body 1, the comb teeth 3 are evenly arranged in a straight line, and the comb teeth 3 are pointed on the head Cylindrical, the diameter of the cylindrical comb teeth 3 is 1.5mm, the height of the comb teeth is 3mm, and the gap between the teeth of the comb teeth is 3mm; the lower end of the knife body between the 3 roots of each comb tooth is in the shape of a blade.

[0017] When removing the hairtail side spines, the tip of the comb teeth 3 aligns with the hairtail side spine gaps and penetrates the fish meat between the hairtail side spines. When piercing, the pointed cylindrical comb teeth 3 on the head will not break the hairtail spines. The thorns are just in the gaps of the 3 comb teeth. Carefully cut the fish skin and fish meat above the side thorns from top to bottom. The...

Embodiment 2

[0019] A hairtail side spine removal knife, its structure is basically the same as that of Embodiment 1, the difference is that the comb teeth 3 are flat with a pointed head, the thickness of the flat comb teeth 3 is 0.7mm, the width is 1.2mm, and the height of the comb teeth is 4mm, comb gap is 4mm.

[0020] When removing the hairtail side thorns, the tip of the comb teeth 3 is aligned with the hairtail side thorn gaps and penetrates the fish meat between the hairtail side thorns. The thorns are just in the gaps of the comb teeth 3, carefully cut the fish skin and fish flesh above the side thorns from top to bottom, the comb teeth 3 with a height of 4mm just make it cut above the side thorns without touching the side thorns, The side thorns will not be cut off; then turn the hairtail over and cut the skin and fish meat on the other side, and finally use the knife along the outside to make the side thorns detach, so as to achieve the purpose of removing the hairtail side thorn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com