Power conversion device and its motor drive device, blower, compressor, air conditioner, refrigerator, refrigerator

A power conversion device and motor technology, which is applied in the direction of motor control, AC motor control, output power conversion device, etc., can solve problems such as the complexity of control software, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

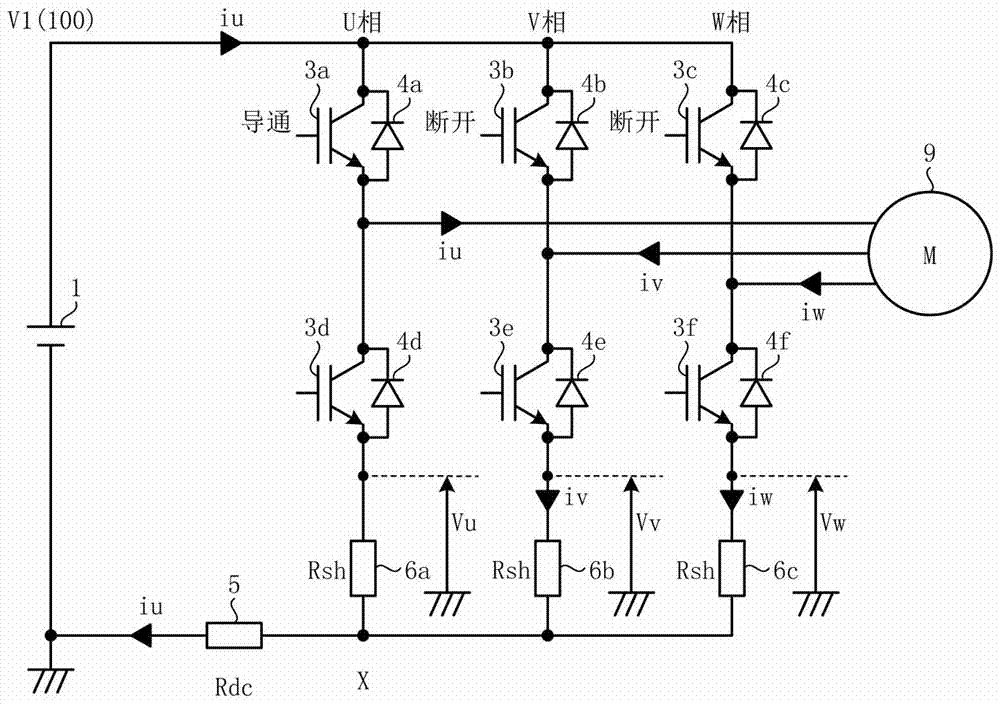

[0054] figure 1 It is a figure which shows one structural example of the power conversion apparatus concerning embodiment. exist figure 1 In the example shown, the power conversion device 100 according to the embodiment is configured to convert the DC power supplied from the DC power supply 1 into figure 1 In the example shown is a 3-phase alternating current supplied by an electric motor 9 .

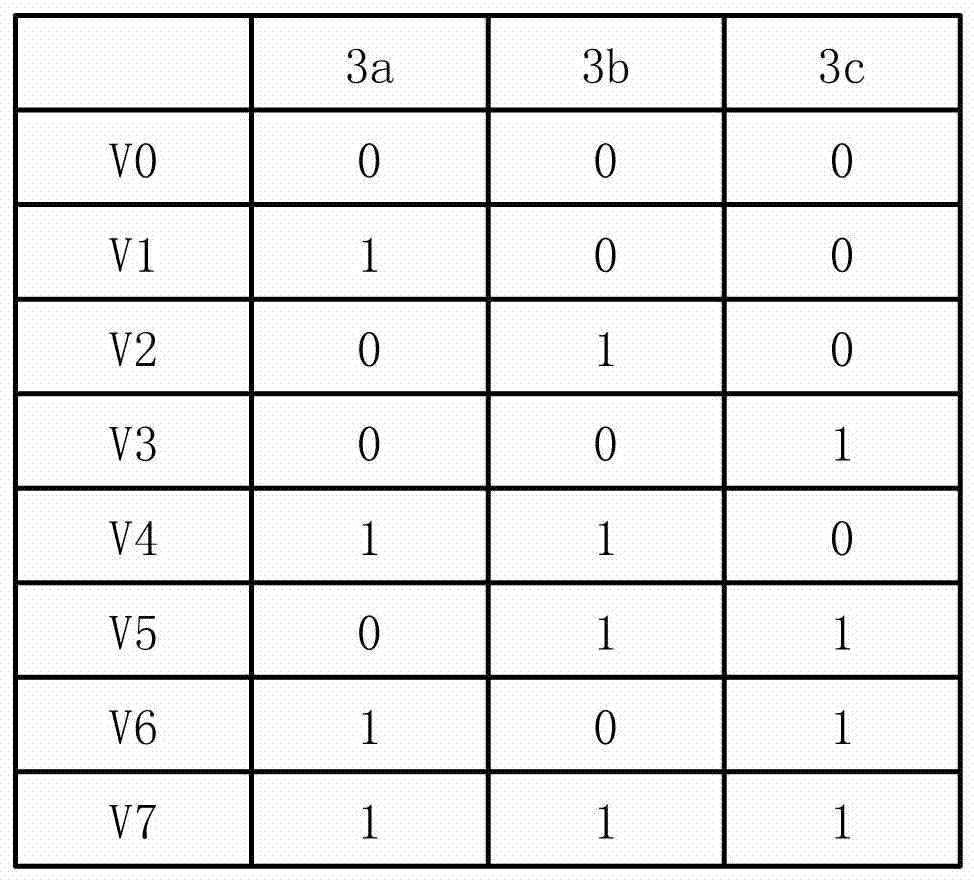

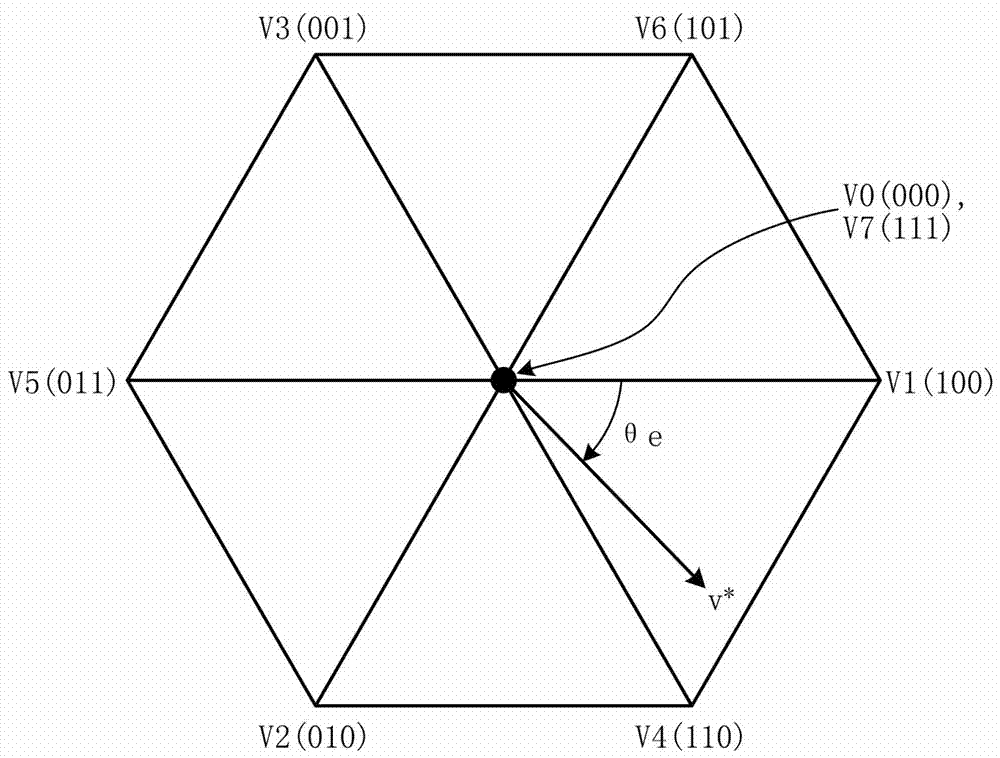

[0055] Such as figure 1 As shown, the power conversion device 100 has the following main components for supplying 3-phase AC power to the load device 9: an inverter 2, which is composed of 3 bridge arms, and the 3 bridge arms include: an upper bridge arm switching element 3a to 3c (here, 3a: U phase, 3b: V phase, 3c: W phase) and lower arm switching elements 3d to 3f (here, 3d: U phase, 3e: V phase, 3f: W phase); and control part 7, which generates six drive signals corresponding to the upper arm switching elements 3a to 3c of each phase and the lower arm switching elements 3d to 3f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com