Method for reducing pull-out vibrations of a friction clutch in a power train of a motor vehicle

A technology of power transmission system and friction clutch, applied in friction clutch, mechanical drive clutch, arrangement of multiple different prime movers of general power plant, etc., can solve problems such as difficult performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

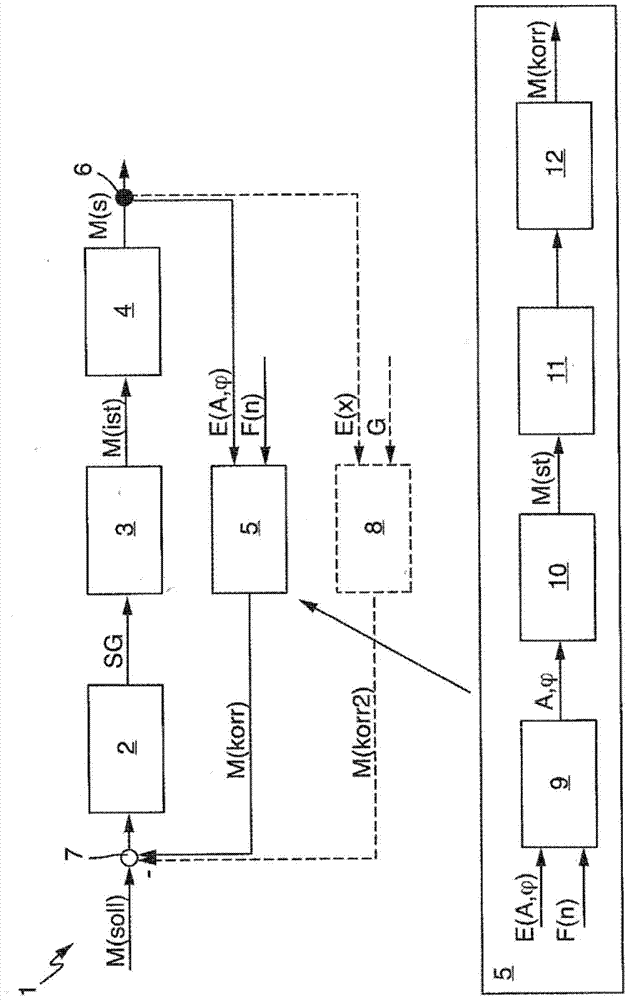

[0025] The invention is explained in more detail on the basis of the single drawing. The accompanying drawings illustrate the blocks of the proposed method figure 1 . box figure 1 The upper part of shows the control of a friction clutch which is automatically controlled by means of a clutch actuator known per se. The control unit outputs the desired clutch torque M(soll) for this purpose. In block 2 , a control variable SG, for example an electric actuator voltage, etc., is determined from the desired clutch value M(soll) on the basis of the clutch characteristic curve. The actual clutch torque M(ist) is regulated by means of the actuator system shown in box 3 , for example in the manner of a pilot control followed by tracking regulation. Box 4 shows the dynamic interaction in the friction clutch and the surrounding drive train, which interaction causes a geometric pull-out vibration. The result is a subsequent vibration-containing clutch torque M(s), for example at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com