Vibration screen optimization design method using Gaussian harmony searching

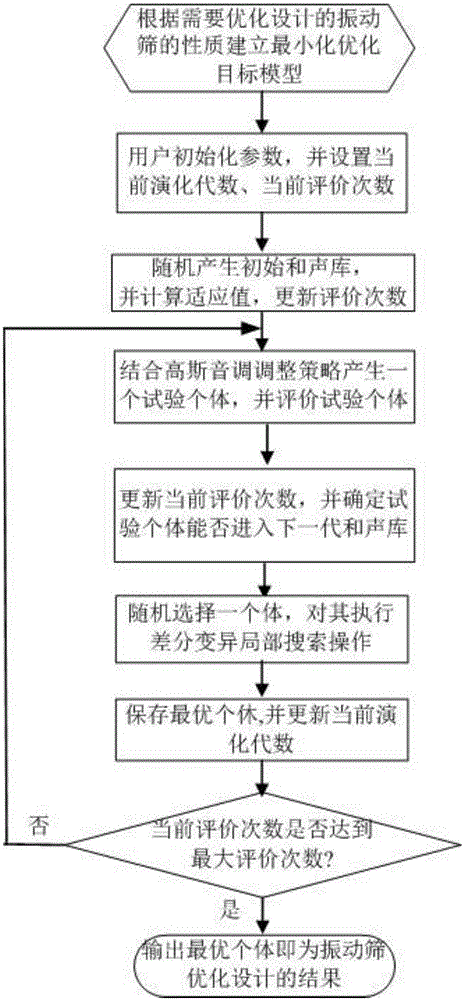

An optimized design, vibrating screen technology, applied in special data processing applications, calculations, instruments, etc., can solve problems such as slow convergence speed, falling into local optimum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

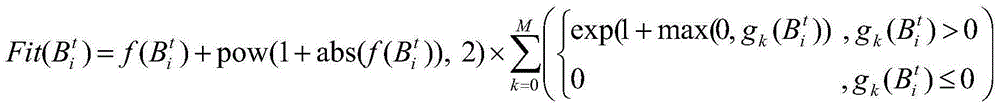

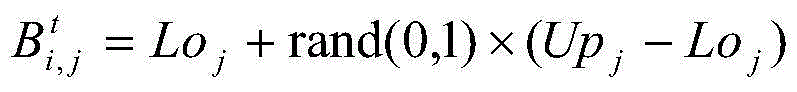

[0056] This embodiment is based on literature (Wang Miao, Duan Zhishan. Optimal Design of Circular Vibrating Screen Based on Particle Swarm Optimization Algorithm [J]. Coal Mining Machinery, 2011, 32 (12), 16-18.) Optimal Design of Circular Vibrating Screen Problem is an example, and the specific implementation steps of the present invention are as follows:

[0057] Step 1. According to the physical and mechanical characteristics of the circular vibrating screen to be optimized, the following form of mathematical model is established to minimize the optimization objective:

[0058] Minimize the optimal design objective function of the circular vibrating screen:

[0059] f ( X ) = 22529.369 x 1 x 2 c o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com