A square column wall-attached air supply with a circular equal-section flow equalization device

A technology with equal cross-section and wall surface, which is applied in the field of uniform cross-section air supply devices, can solve the problems of not being suitable for large-space buildings and application restrictions, and achieve the effects of improving the uniformity of the air outlet, improving the effectiveness, and lengthening the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

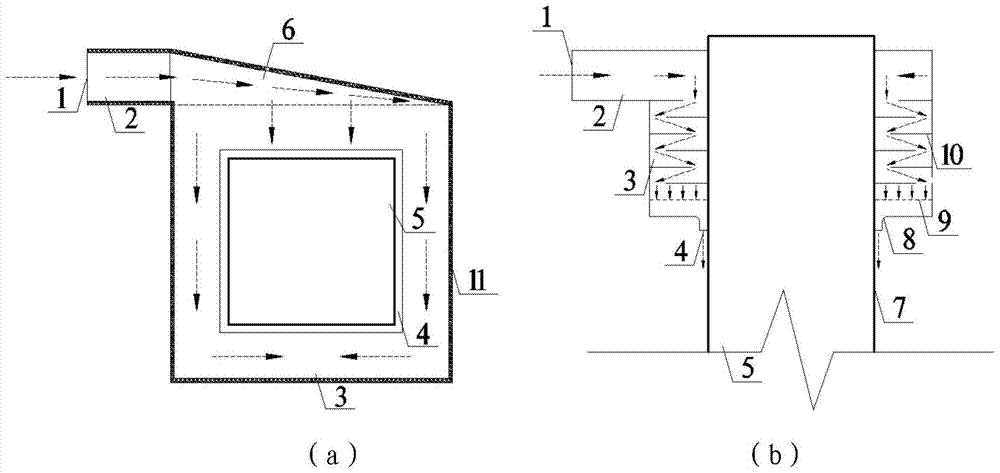

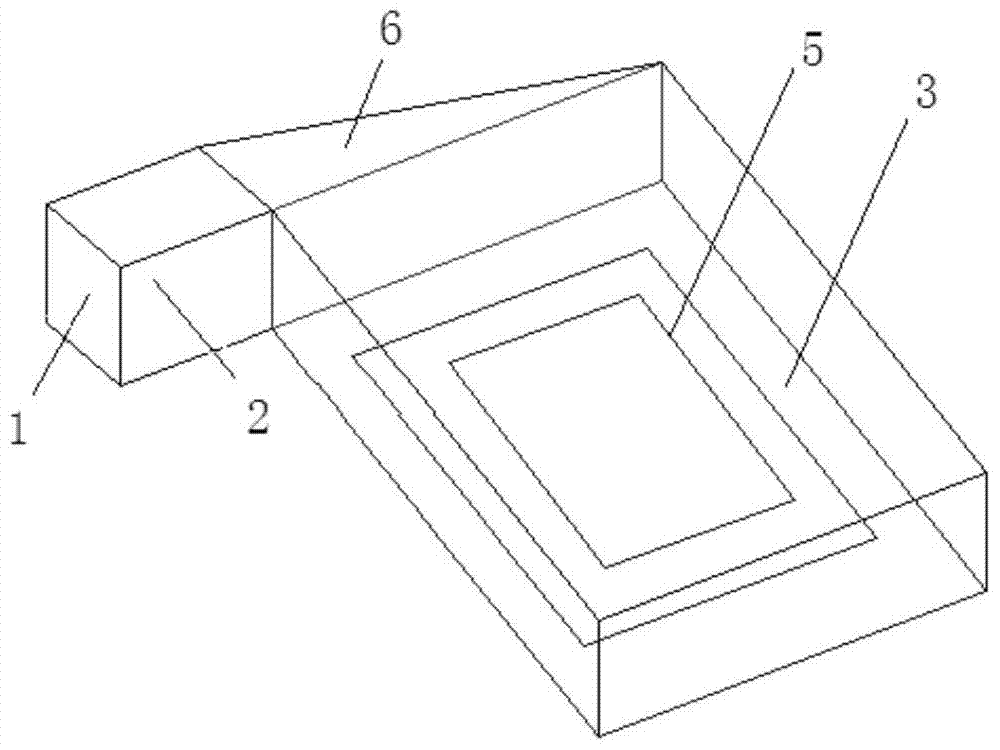

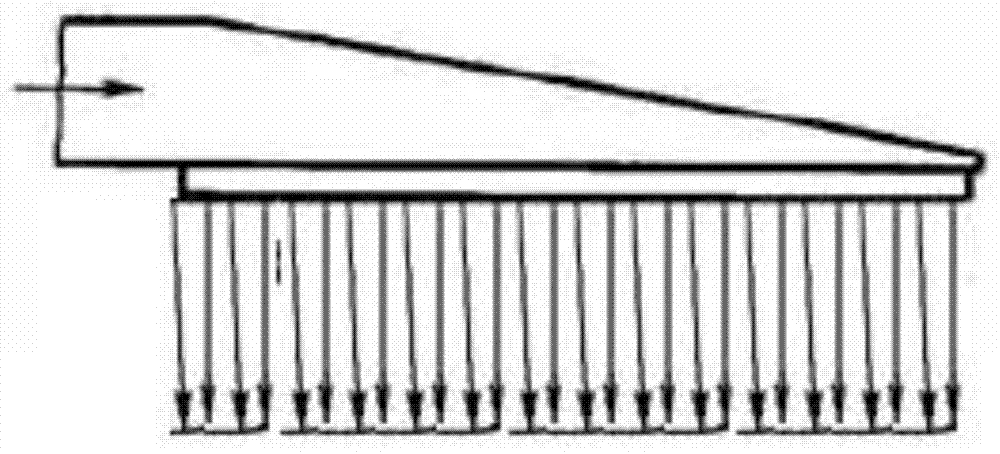

Embodiment 1

[0050] According to the actual use situation, the experimental model of the return-shaped equal-section flow equalization device is established, and the square column with a side length of 1000mm is used as the application object. The diameter of the shell 3 is 1700mm, and the total height is 1080mm (the height of the uppermost return-shaped air duct is 300mm, 6 The height of the 5 flow areas separated by the back-shaped partition 10 is 100 mm, the height of the flow-sharing area between the back-shaped orifice 9 and the adjacent round-shaped partition 10 is 100 mm, the height of the air outlet area is 100 mm, and the height of the diversion section is 100 mm. 80mm, 1080mm in total); the vertical length of the wedge-shaped air inlet 6 is 1000mm, the height is 300mm, the width of the inlet of the air inlet 6 is 300mm, and the width of the end is 0mm; The bottom surface of the return-shaped air duct of the device is installed horizontally, and the width of the other five return-s...

Embodiment 2

[0058] Others are the same as in Embodiment 1, and the number of return-shaped partitions is 4 (corresponding to the total height of the housing of the current equalizing device of 880 mm). When the design air supply speeds are 1.0, 1.5 and 2.0m / s respectively, when the flow equalization device of the present invention is adopted, the maximum difference between the speed of the 20 measuring points and the design value is 17.0%, 16.0% and 16.5%, and the average deviation is 11.4% respectively , 9.9% and 11.7%; when the traditional hollow shell static pressure box device is used, the maximum difference between the speed of the 20 measuring points and the design value is 73.0%, 89.3% and 75.0%, and the average deviation is 25.6%, 26.1% and 26.5% %. Compared with the latter, the wind output accuracy of the former is increased by 124.6%, 163.6% and 126.5% respectively.

[0059] In terms of the air outlet uniformity of the return-shaped slit air outlet, the unevenness of the return...

Embodiment 3

[0060] Others are the same as in Embodiment 1, and the number of return-shaped partitions is 2 (corresponding to the total height of the housing of the flow equalizer 680mm). When the design air supply speed is 1.0, 1.5 and 2.0m / s respectively, when using the current equalizing device of the present invention, the maximum difference between the speed of 20 measuring points and the design value is 29.0%, 32.7% and 37.5%, respectively, and the average deviation is 14.7% respectively , 16.8% and 16.8%; when the traditional hollow shell static pressure box device is used, the maximum difference between the speed of the 20 measuring points and the design value is 90.0%, 104.0% and 103.5%, and the average deviation is 27.5%, 27.6% and 27.1% %. Compared with the latter, the air output accuracy of the former is increased by 87.1%, 64.3% and 61.3% respectively.

[0061] In terms of air outlet uniformity of the return-shaped slit air outlet, using the return-shaped equal-section flow e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com