Gate valve

A gate valve and valve plate technology, applied in the field of valves, can solve the problems of valve plate and/or sealing slope inclination change, sealing instability, valve plate wear, etc., and achieve the effect of a simple and reliable fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

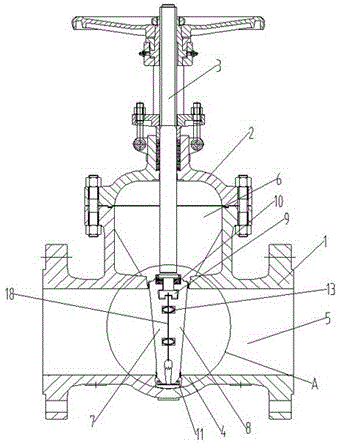

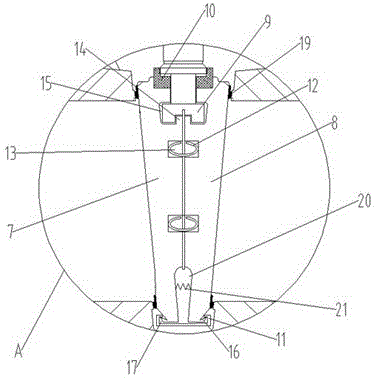

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] like figure 1 As described above, a gate valve includes a valve body 1, a valve cover 2, a valve seat 4 and a valve plate assembly. The valve cover 2 is installed on the top of the valve body 1 by bolts. There is a flow channel 5 for fluid circulation, the valve seat 4 is set in the flow channel 5, and the valve seat 4 is provided with a valve plate groove matching with the valve plate assembly, the valve plate assembly is arranged in the valve plate groove, the valve stem 3 From the valve cover 2 into the upper chamber 6, the valve stem 3 and the valve cover 2 are sealed by a sealing structure, and the lower end of the valve stem 3 is connected to the upper part of the valve stem 3 assembly, wherein the valve plate assembly includes a left valve plate 7, a right valve plate 8, The valve plate sleeve 9, the fixed ring 10, the clip sleeve 11 and the elastic metal rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com