A movable civil explosives warehouse and its construction method

A technology for warehouses and items, applied in industrial buildings and other directions, can solve the problems of safety monitoring, intrusion and anti-theft restrictions, easy to attract external attention, uneven light distribution, etc., to shorten the construction period, easy to transport, and light in weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

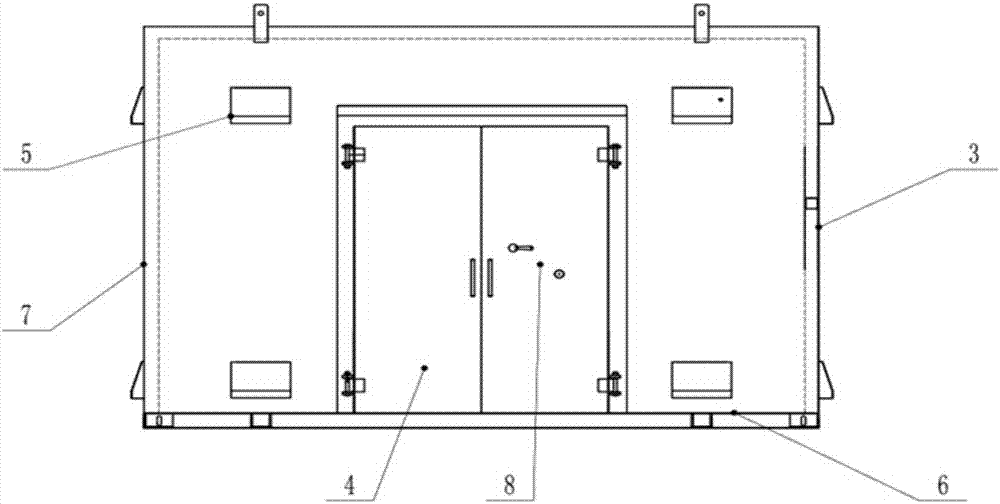

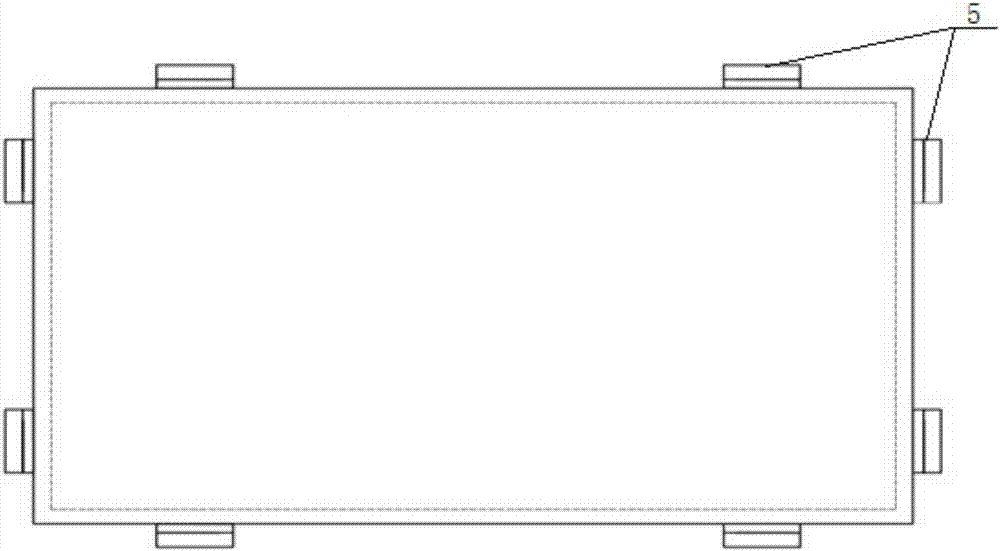

[0041] Such as Figure 1 to Figure 4 As shown, this embodiment provides a mobile storehouse for civil explosives, the storeroom size length × width × height is 4.0m × 2.5m × 2.8m, the shape of the storehouse can be made into various shapes, but it needs to be closed, this implementation The warehouse provided in the example is a six-sided warehouse, which includes a frame 1 integrally formed by welding square steel, and the frame 1 adopts a cross welding method; an antistatic layer 6, inner skin, skeleton and For the outer skin, the inner skin, the skeleton and the outer skin are arranged sequentially from the inside to the outside on the side wall 7 and the top of the warehouse; a warehouse door 4 is opened on the side wall of the warehouse,

[0042] Wherein, the antistatic layer 6 is an antistatic flame retardant PVC rubber sheet, and the antistatic flame retardant PVC rubber sheet is bonded to the upper surface of the inner skin by glue.

[0043] The inner and outer skins ...

Embodiment 2

[0051] This embodiment provides a mobile storehouse for civil explosives, the structure of which is as described in Embodiment 1, the difference is that the antistatic layer 6 is a colored antistatic rubber, which is bonded to the upper surface of the inner skin by glue. The inner and outer skins at the bottom of the warehouse are made of steel plates with a thickness of 6mm.

[0052] The inner skin of the warehouse side wall 7 and the top is a steel plate with a thickness of 6 mm, and the outer skin is an aluminum plate with a thickness of 6 mm.

[0053] Fill rock wool, a grade A refractory material, between the layers of heat-insulating rock wool cloth at the bottom of the warehouse.

[0054] Perlite concrete is filled between the inner skin and the outer skin of the side wall 7 and the top of the warehouse.

[0055] In addition, in order to increase the rigidity of the frame and improve its impact resistance, a square steel reinforcing bar is added to the frame. impact. ...

Embodiment 3

[0057] This embodiment provides a mobile storeroom for civil explosives, the structure of which is as described in Embodiment 1, the difference being that the storeroom also includes an optical fiber lighting system, which includes a light source connected according to the prior art, a reflector, Color filter and optical fiber, the light source, reflector and color filter are all arranged outside the warehouse, and the optical fiber is introduced into the warehouse for lighting. For example, in this embodiment, the optical fiber can be used to transmit the lights of the remote monitoring room and the office to the warehouse, and the installation position of the optical fiber lighting is arranged on the top of the warehouse.

[0058] Fix the luminescent light source outside the mobile warehouse, and use optical fiber to transmit the light from the light source to the mobile warehouse. The light source can be natural light or artificial light. In this embodiment, the traditional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com