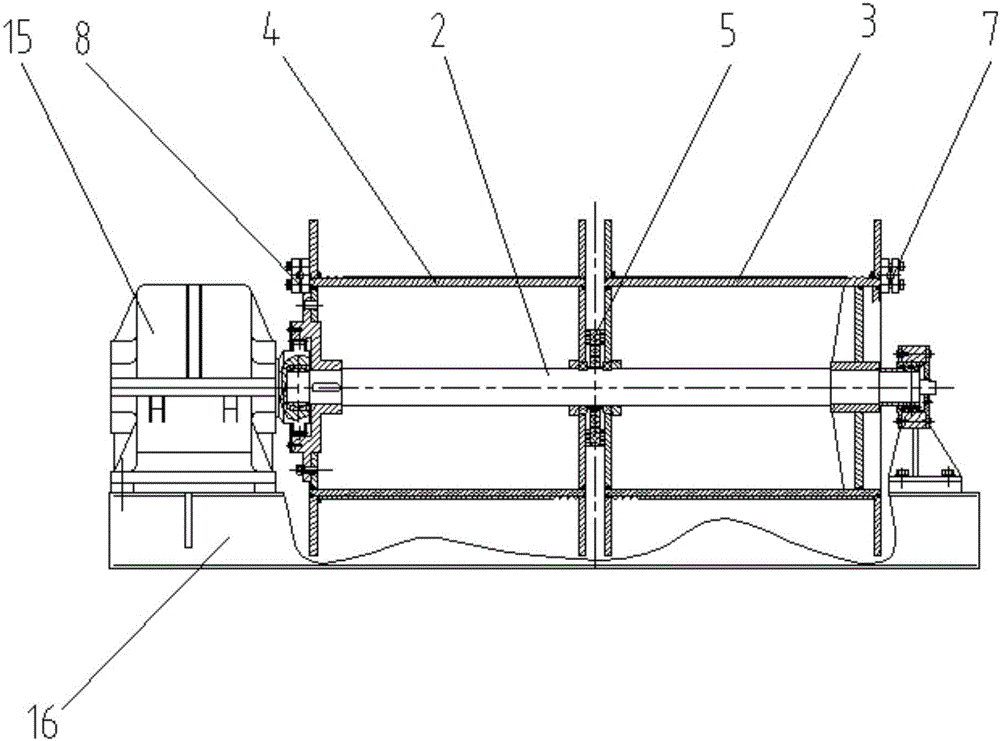

Reel device and hoisting mechanism of crane

A technology of hoisting mechanism and crane, which is applied in hoisting device, clockwork mechanism, etc., and can solve problems affecting the performance of tower cranes, disordered wire rope arrangement, impact of related parts of hoisting mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

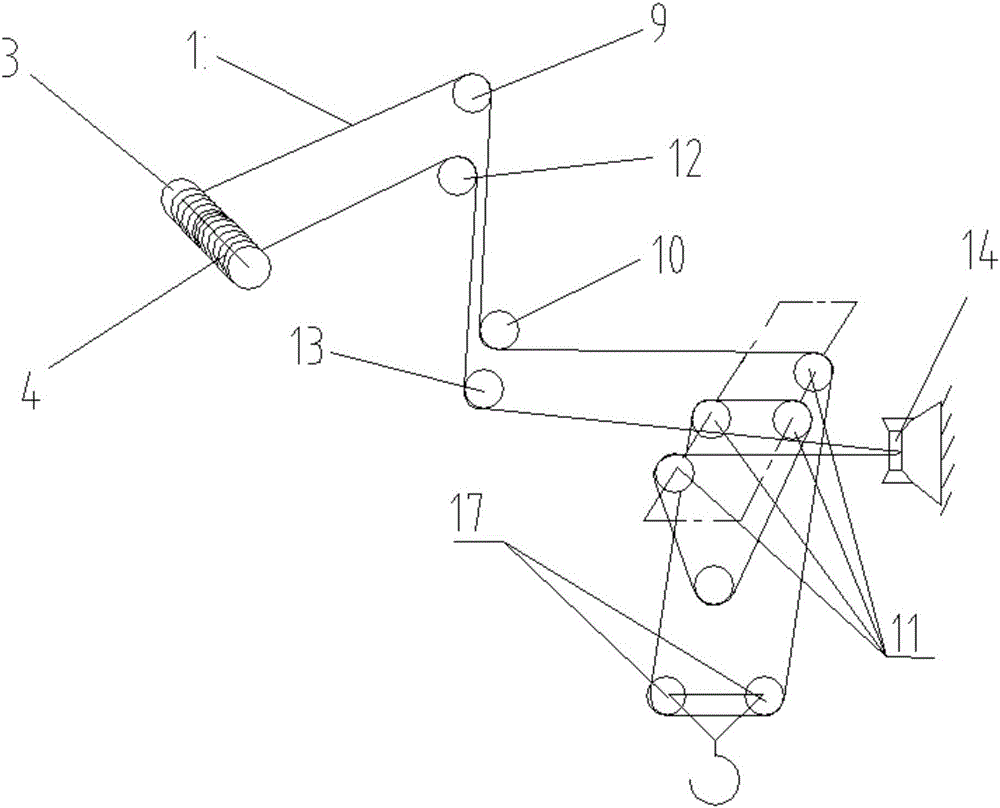

Method used

Image

Examples

Embodiment approach

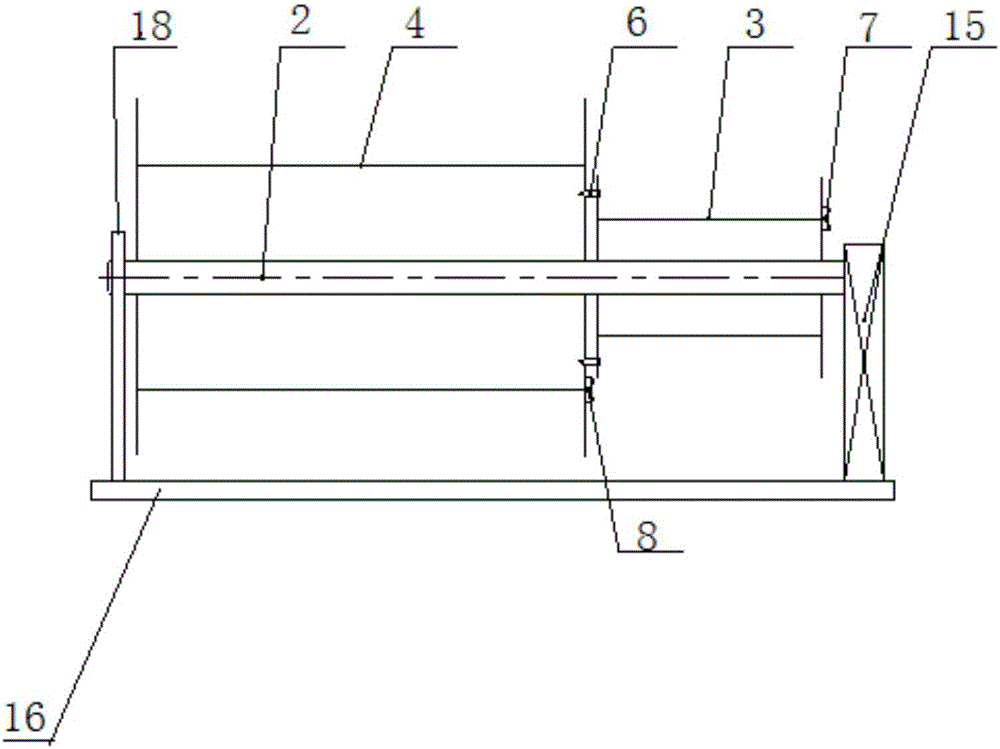

[0039] see image 3 , according to the second embodiment of the present invention, the first reel body 3 can be power-connected with the drive shaft 2, the second reel body 4 is sleeved on the drive shaft 2, and the first reel body 3 and the second reel body Mounting holes for insertion of the insert 6 are respectively formed on the body 4, so that the first roll body 3 and the second roll body 4 can be connected when the insert piece 6 is inserted into the respective mounting holes of the first roll body 3 and the second roll body 4. The second reel body 4 is power connected. The insert 6 can be, for example, a pin shaft. In addition, the mounting holes can be formed at the ends of the first roll body 3 and the second roll body 4 facing each other, and along the first roll body 3 and the second roll body. A plurality of installation holes are distributed in the circumferential direction of 4, so that a plurality of inserts 6 can be adaptively used to improve the connection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com