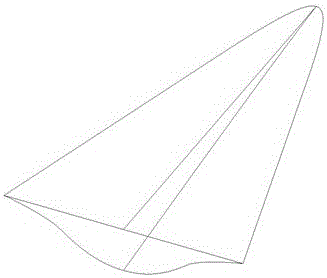

A Close Cone Waverider with Curved Head with Controllable Sweep Angle

A technology of sweep angle and waverider, which is applied in the direction of aircraft control, affecting the air flow flowing through the surface of the aircraft, aircraft parts, etc., can solve the problems of reduced aerodynamic performance, poor low-speed performance, and difficult design of the upper surface, etc., to achieve improved Aerodynamic performance, design favorable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention installs the following steps to implement:

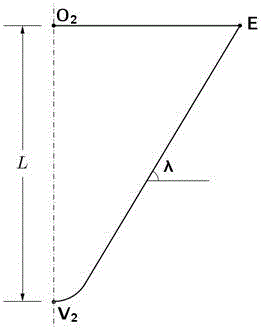

[0046] 1. According to the design requirements, the cruising Mach number, flight altitude, fuselage length and deviation from the center of the circle are given;

[0047] 2. To determine the sweep angle, first determine the upper limit of the sweep angle of the waverider by the cruise Mach number, and then select a reasonable sweep angle according to the design requirements;

[0048] 3. To determine the shock angle, first determine the variation range of the shock angle by the cruise Mach number and the upper limit of the sweep angle, and then select a reasonable shock angle according to the design requirements;

[0049] 4. Given the curved surface of the flow capture pipe, the curved surface is determined by the projection curve of the flow capture pipe on the plane where the bottom of the waverider is located. In order to ensure a straight leading edge, the curve adopts a straight line segment with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com