Installation Auxiliary Tooling and Assembly Method for Fitting Bolts of Ship Shafting Flange

A technology of bolts and flanges, which is applied in the field of installation related to large-scale shafting, can solve the problems of ship construction period delay, close-fitting bolts cannot use tight-fitting bolt holes, and large axial deflection of holes, etc., so as to reduce the time spent on installation, The effect of improving shipbuilding production efficiency and reducing operation risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, but the protection scope of the present invention cannot be limited by this.

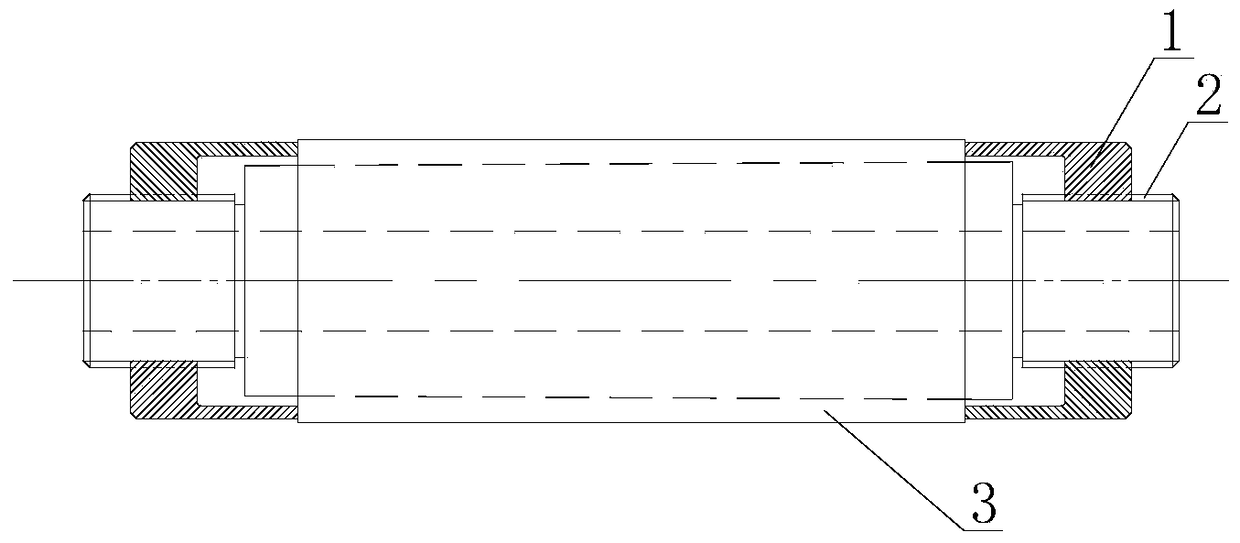

[0038] see first figure 1 , figure 1 It is a structural schematic diagram of the installation auxiliary tooling of the ship shafting flange tight fitting bolts of the present invention. It can be seen from the figure that the installation auxiliary tooling for the tight fit bolts of the ship shafting flange includes three parts: nut 1, barrel core 2 and jacket 3, in which the thread of nut 1 matches the threads at both ends of barrel core 2.

[0039] The nut 1 is in an irregular form, and the core 2 can be separated from the outer casing 3 by screwing in the nut, and its thread is a fine thread with a pitch of 2 mm.

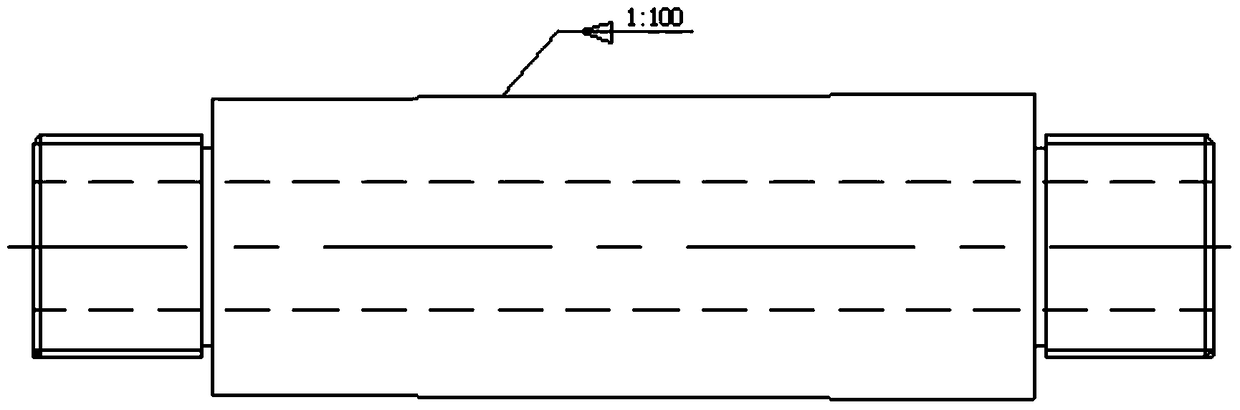

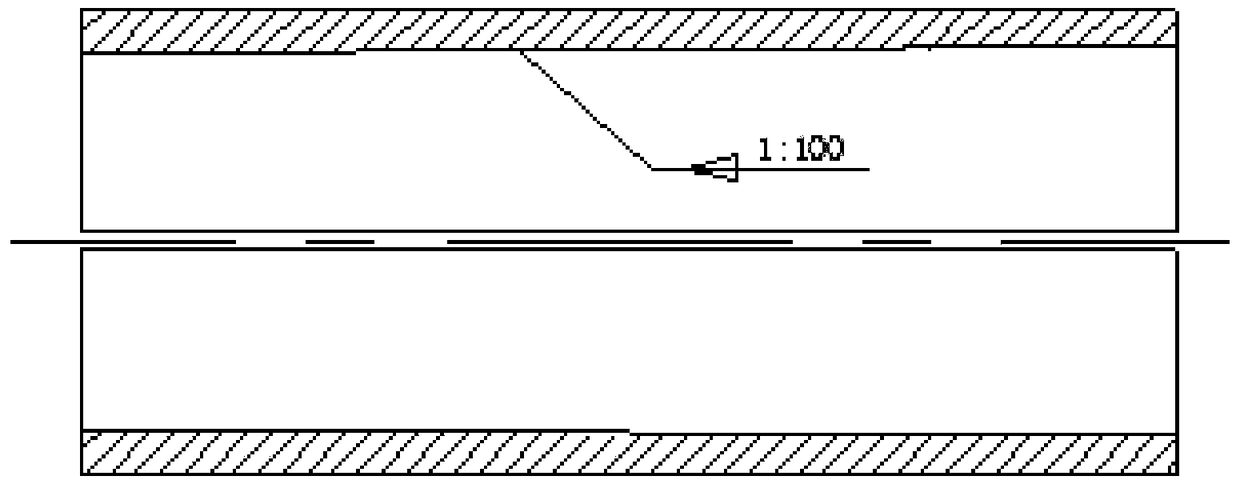

[0040] The core 2, such as figure 2 , the two ends are fine threads with a pitch of 2 mm, the middle is a cone with a taper of 1:100, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com