Reloading method of molding plastic extruding machine hopper

A technology for extruders and hoppers, which is applied in the field of refueling the hoppers of molding extruders. It can solve the problems of material residues, high labor intensity of workers, and difficulty in changing materials, and achieve the effect of avoiding material scattering and less additional operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

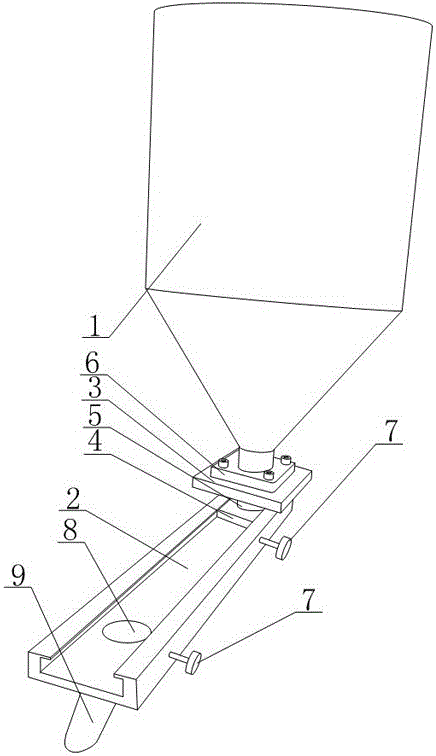

[0020] like figure 1 As shown in the figure, the present invention is a method for refilling a hopper of a molding extruder, comprising a hopper body 1, and the hopper body 1 includes a cylindrical storage cylinder, and a funnel-shaped discharging structure is connected to the bottom of the storage cylinder; it also includes The chute 2, which is fixedly installed on the extruder, is in the shape of a cuboid as a whole, with an opening on the surface and a cavity inside. The bottom of the chute 2 is provided with a feed port that communicates with the extruder, a lower slider 4 is installed in the chute 2, and two locking bolts 7 are arranged on the side of the chute 2, and the two locking bolts 7 are respectively connected to the feeder. The port corresponds to the discharge hole 8. The upper slider 3 is installed above the lower slider 4. The upper slider 3 is located on the chute 2. The upper slider 3 and the lower slider 4 are communicated through the pipe 5, and the chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com