Multi-hole, multi-plane and same-direction finish machining fixture for large castings

A large-scale casting, multi-plane technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that affect the local dimensional accuracy of large castings, poor positioning accuracy, long processing period, etc., to improve repeatability The effects of positioning accuracy, reducing labor intensity, improving finish and processing dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

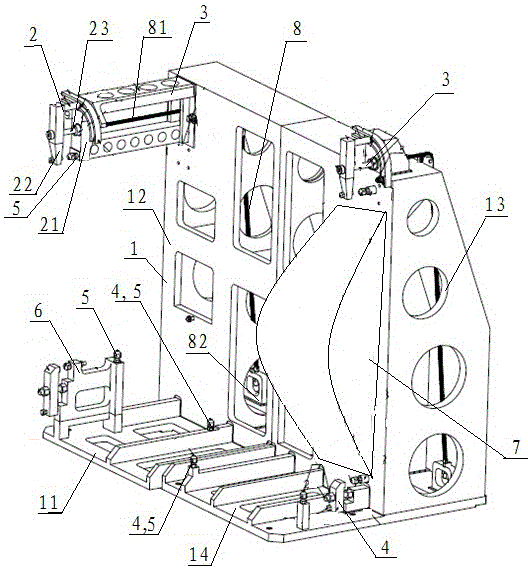

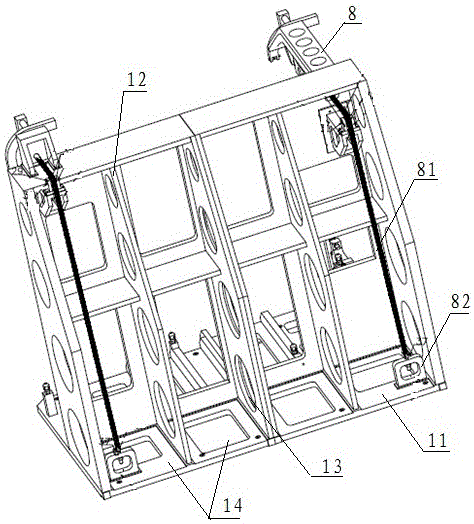

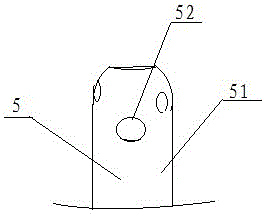

[0018] Such as figure 1 As shown, the jig for large-scale casting porous multi-plane finishing in the same direction includes several L-shaped supports 1 connected in parallel, the horizontal parts of each L-shaped support 1 are connected to each other, and are provided with upward horizontal support protrusions 11, The vertical part of each L-shaped support 1 protrudes backward to form a vertical reinforcing rib 12; on the horizontal protrusion 11 of the L-shaped support 1 and at the position of the vertical reinforcing rib 12 near its top position, there are not several Lower and upper support bases 3, 4, each lower support base 3 is connected to the part 7 to be processed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com