Efficient rice and wheat threshing machine

A thresher, rice and wheat technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as potential safety hazards, environmental pollution, waste of resources, etc., achieve a simple structure, be conducive to recycling, and avoid environmental pollution. and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

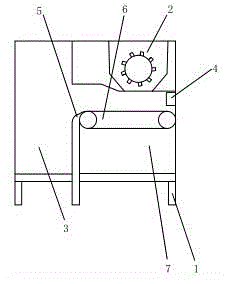

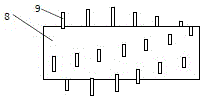

[0013] figure 1 , figure 2 The high-efficiency rice and wheat thresher provided by the present invention is shown, including a frame 1, a threshing bin 2 and a straw bin 3 arranged on the frame 1 and front and back; A straw conveying area is formed between the conveyer belt 6 and the exit of the threshing bin 2, and the straw conveying area is connected with the straw bin 3; the straw conveying belt 6 is a mesh-shaped conveying belt, and a rice collecting bin 7 is arranged below the straw conveying belt 6; The threshing bin 2 is provided with a threshing cylinder 8, and the threshing cylinder 8 is provided with threshing teeth 9, and the threshing teeth 9 are arranged in multiple rows on the surface of the threshing cylinder 8 in a helical manner along the axial direction of the threshing cylinder 8, and the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com