Vibrating screen wind deflector structure for harvester

A technology of vibrating screen and wind deflector, applied in harvester, application, cutter and other directions, can solve the problems of guiding and air guiding effect is not very good, and achieve the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

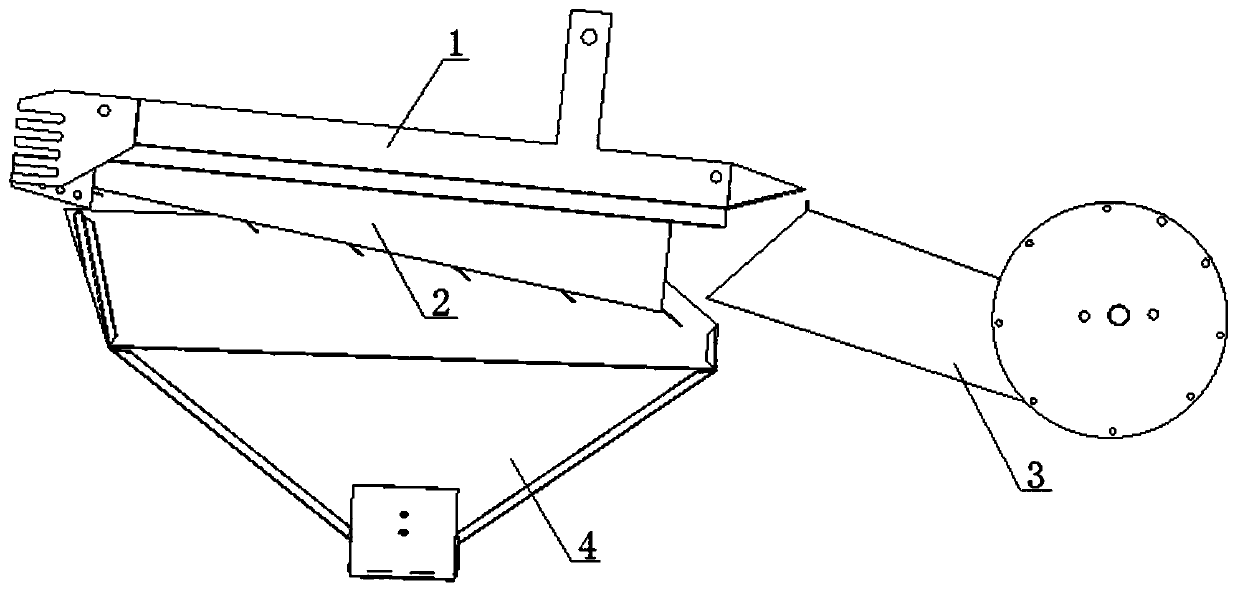

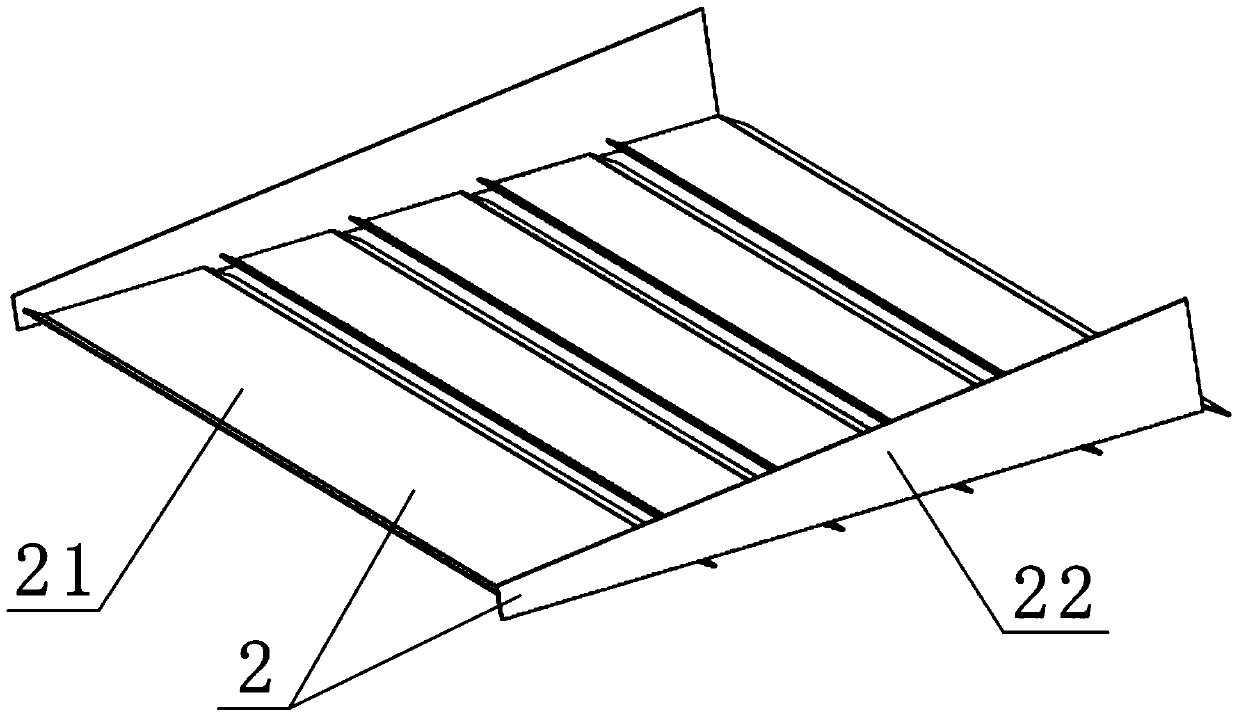

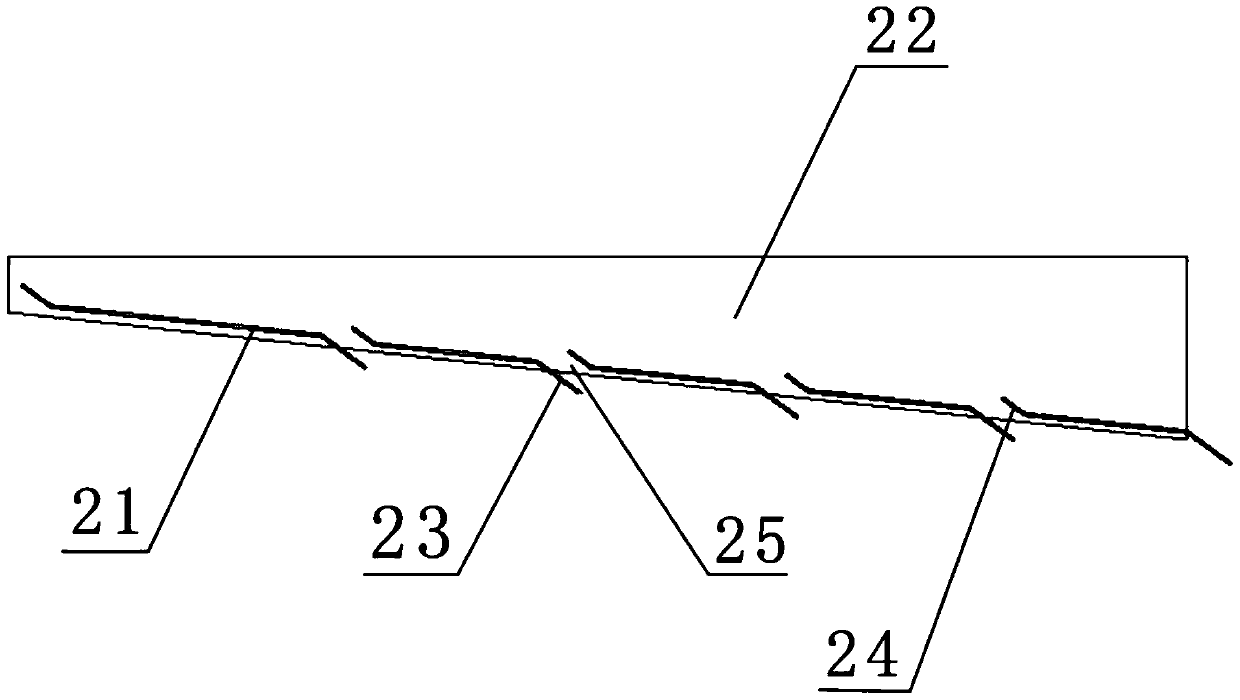

[0021] Such as Figure 1 ~ Figure 3 As shown, a vibrating screen wind deflector structure used on a harvester includes a vibrating screen 1, a wind deflector 2, a fan 3 and a grain collection bin 4, the vibrating screen 1 is installed on the cleaning device of the harvester, and the vibrating screen 1 The bottom is matched with the wind deflector 2, and the bottom of the wind deflector 2 is matched with the installation of the grain collection bin 4; the vibrating screen 1 is evenly provided with several sieve holes, and the wind deflector 2 is fixedly connected to the wind deflector bottom 21 by the wind deflector bottom plate 21. The wedge-shaped wind-guiding side plate 22 is composed of wedge-shaped wind-guiding side plate 22 in a wedge-shaped shape, the wind-guiding bottom plate 21 and the two wedge-shaped wind-guiding side plates 22 together form a wind-guiding wedge-shaped cavity, and all the screen holes of the vibrating screen 1 are aligned with the wind-guiding wedge-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com