Cast copper rotor for variable frequency motor

A frequency conversion motor and copper casting technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of rotor loss and increased motor loss, and achieve the effects of low rotor resistance, reduced rotor loss, and improved motor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

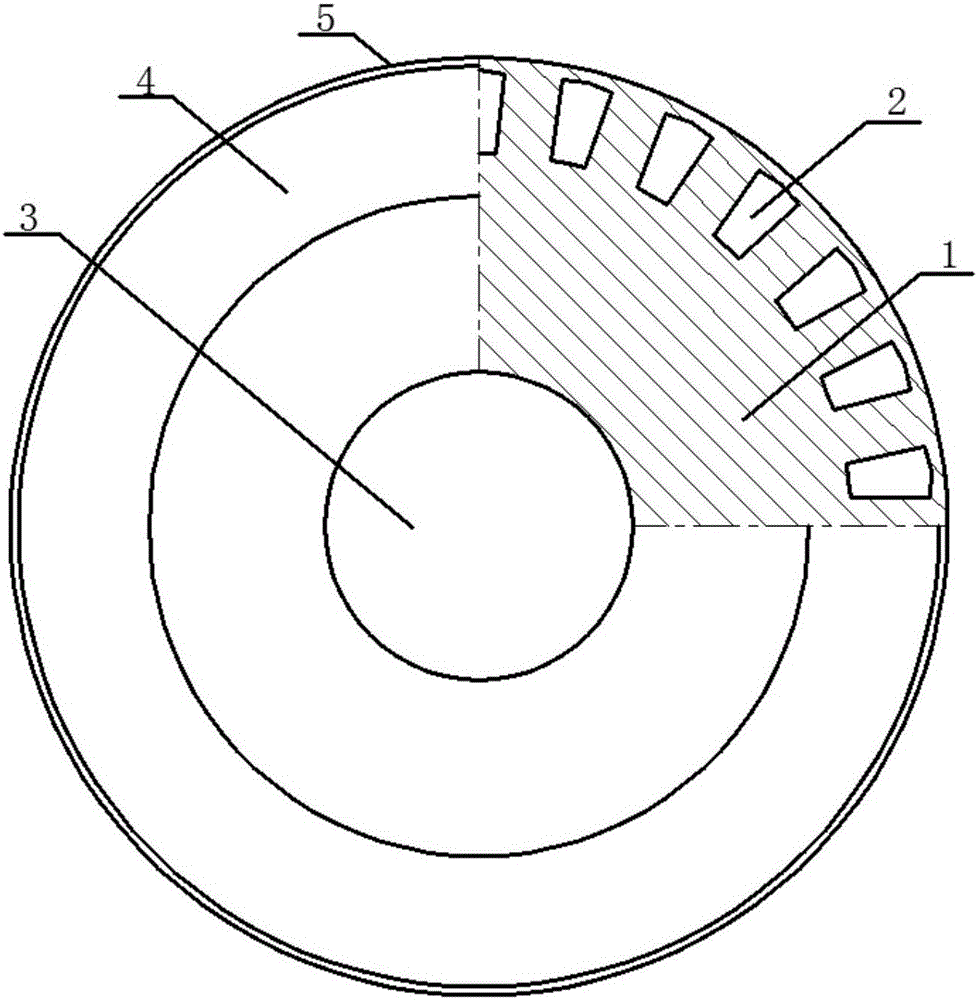

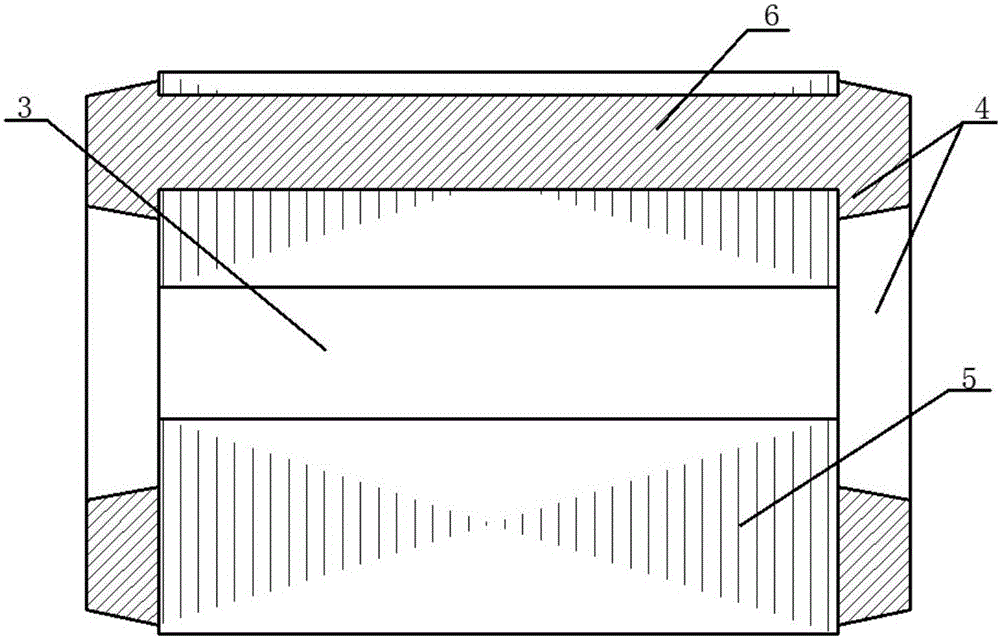

[0017] like figure 1 or figure 2 As shown, the rotor core 5 is formed by laminating a plurality of rotor laminations 1 of the same size and shape. The central circular hole structure of the rotor sheet 1 is laminated to form a shaft hole 3 for installing the motor shaft. A certain number of closed guide bar holes 2 are evenly distributed on the circumference of the rotor sheet 1. The guide bar holes 2 are in an inverted trapezoidal structure with a wide top and a narrow bottom. After lamination, a guide bar groove for pouring cast copper guide bars 6 is formed. The number of guide bar holes 2 is determined according to the performance requirements of the frequency conversion motor using the present invention, and the present embodiment is 26.

[0018] The cast copper guide bar 6 and the cast copper end ring 4 are die-cast to form an integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com