An oil-free scroll air compressor

An air compressor and scroll technology, which is applied in the field of oil-free scroll air compressors, can solve the problems of low oil content compressed air, high cost, complex design of oil-injected air scroll compressor systems, and environmental damage to lubricating oil, etc., to achieve Reduce production cost, convenient and fast installation, and stable rotation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

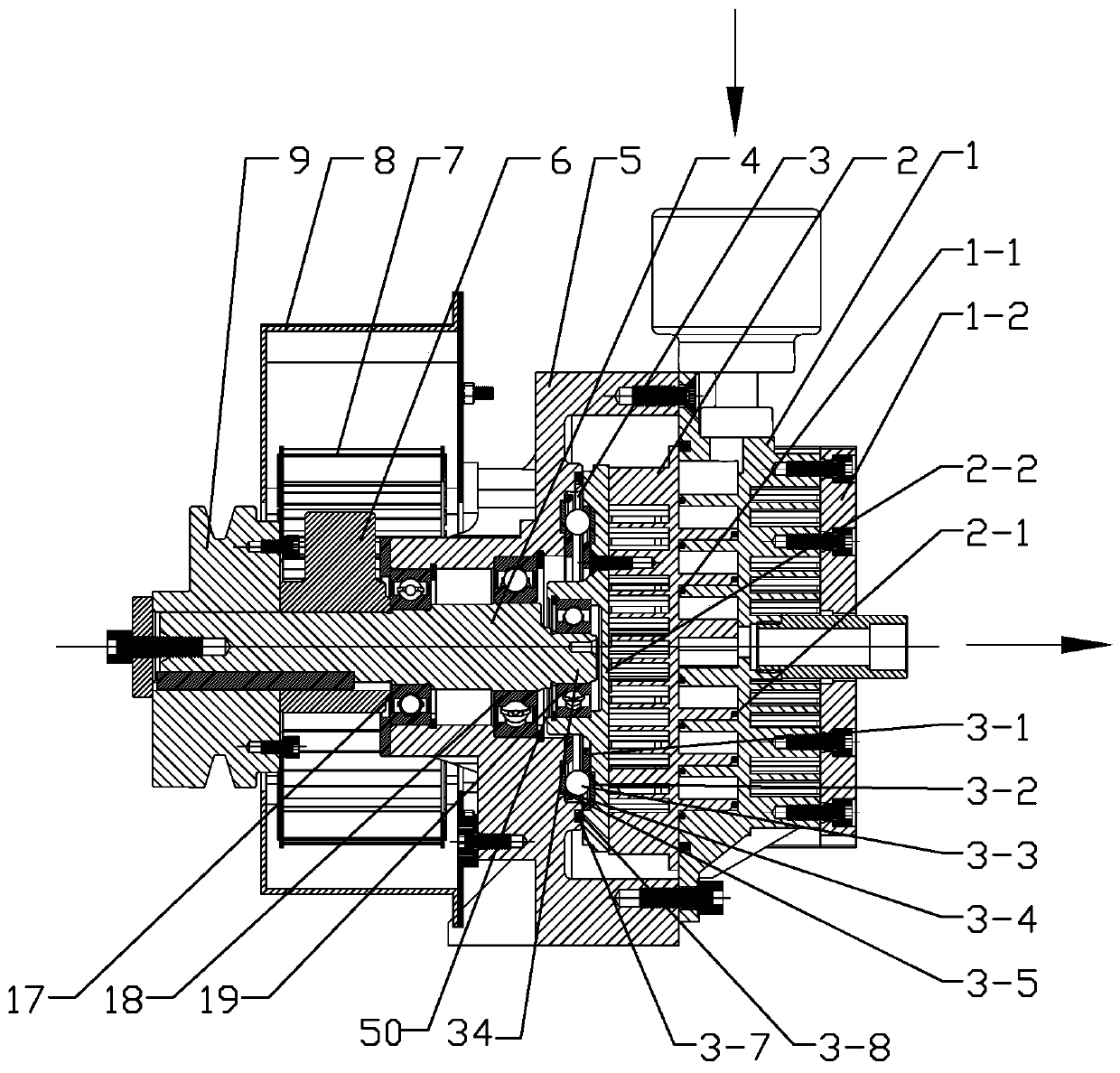

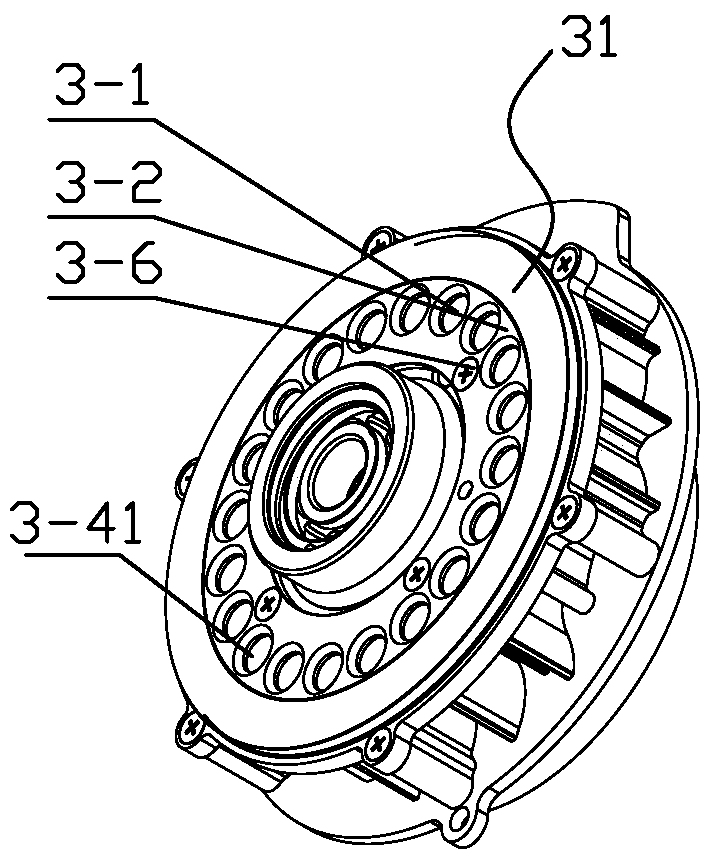

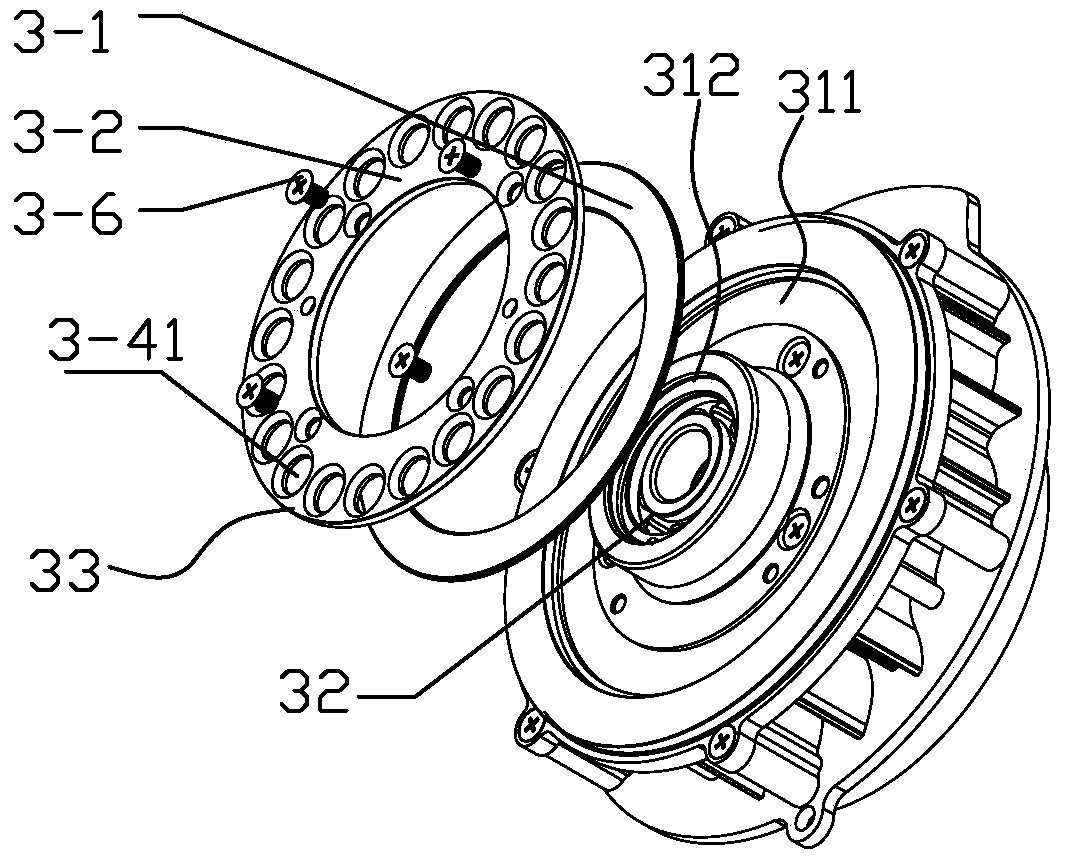

[0025] refer to Figure 1 to Figure 5 The shown oil-free scroll air compressor includes a fixed scroll 1, a moving scroll 2, a crankshaft 4, a frame 5, a main balance weight 6, a pulley 9, an air suction port and an exhaust port. The above-mentioned moving scroll 2 and fixed scroll 1 mesh to form a compression chamber of air; There is a ball disc structure 3, the ball disc structure 3 includes a fixed seat 31 installed on the frame 5, the fixed seat 31 is provided with a radial bearing 32 and a thrust bearing 33, the fixed seat 31 is provided with a mounting hole 312, the radial bearing 32 is fixed in the installation hole 312, and is installed on the eccentric shaft 34 at one end of the crankshaft 4; the thrust bearing 33 is fixed on the side of the fixed seat 31, and is close to the side of the frame 5; The radial bearing 32 and the thrust bearing 33 are concentric shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com