Sheet workpiece transferring device with anti-skidding structure

A sheet-shaped workpiece, anti-slip technology, applied in the direction of object supply, sending objects, conveyor objects, etc., can solve the problem of affecting the state of the tape and transfer efficiency, the clamping mechanism is inconvenient to lift the tape and stick it to a new position, and it is difficult to maintain the tape State and other issues, to achieve the effect of convenient transfer operation, prevent slipping, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

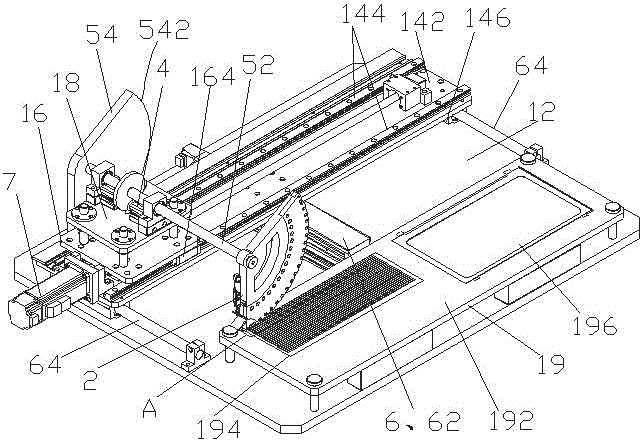

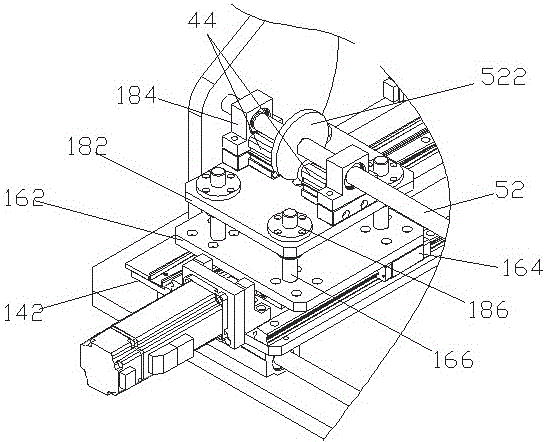

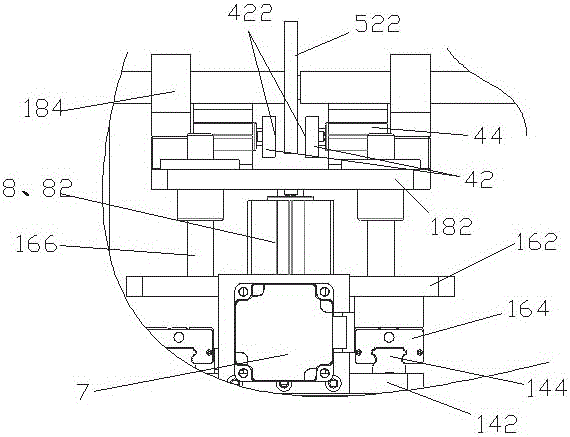

[0042] Such as Figure 1-8 As shown, a device for transferring sheet-shaped workpieces with an anti-skid structure is specifically suitable for a strip-shaped sheet-shaped workpiece, which includes a working head 2. The working head 2 has an arc-shaped working surface 242, and the arc-shaped working surface 242 When rotating around the axis, each position in the bending direction can successively capture the position tangent to itself on the workpiece and gradually release the corresponding position of the workpiece. The arc-shaped working surface 242 of the working head 2 is set facing a worktable 19, and The table top of the workbench 19 is perpendicular to the rotation plane of the arc-shaped work surface 242. The arc-shaped work surface 242 can rely on direct or indirect friction between the table surface to realize lateral rolling on the table surface. The axial side of the arc-shaped work surface 242 is also provided with a Anti-slip mechanism, the anti-slip mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com