High-altitude suspended formwork and its construction method

A cantilever and formwork technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc., can solve the problems such as the inability to guarantee the safety, the difficulty of erecting the external support formwork, and the high construction cost. , to avoid welding and dismantling work, save construction resources investment, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

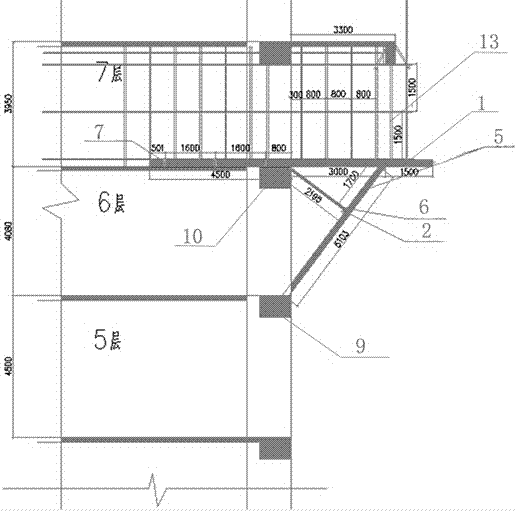

[0040]Embodiment 1: As a very important temporary project in the actual project, the formwork support project directly determines the safety of the project. As a special structural form, the cantilever structure has a disturbance proportional to the fourth power of the span. It can be seen that the influence of the span on the components is extremely significant. The technicians calculated and analyzed the mechanical performance of the formwork support system with a high-altitude cantilever span of 3.7m. The force model of the cantilever and the force of the steel pipe frame of the cantilevered platform are calculated, and the deformation monitoring of the frame is recorded. The following high-altitude cantilever formwork construction method is adopted.

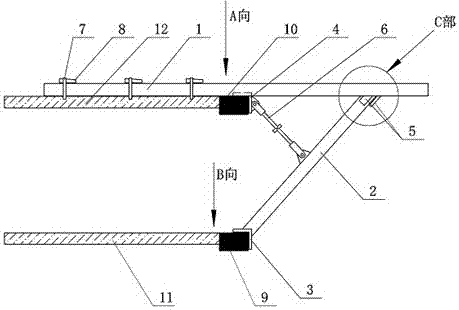

[0041] For the construction method of high-altitude cantilevered formwork, please refer to figure 1 , figure 2 and image 3 , pre-embedded angle steel parts are pre-embedded in the beam on the fifth floor, and the bottom ...

Embodiment 2

[0099] Example 2: see Figure 2-Figure 8 , the high-altitude suspended formwork can be composed of multiple layers, and each layer is gradually extended, and its construction method is basically the same as that of embodiment 1. The structural relationship is as follows: a diagonally braced I-steel support 5 is welded below the end of the cantilevered I-steel 1 or near the end, and the diagonally braced I-steel support 5 includes an inclined base 52 and two side splints 51 It is matched and docked with the end of the diagonal brace I-beam 2; the bottom angle steel 3 is welded and fixed at the bottom of the diagonal brace I-beam 2, and the bottom angle steel 3 is matched and fixed with the edge of the n-story beam; according to the structural requirements, it is pre-prepared when pouring concrete on the n+1 floor Buried φ22 steel bar U-row clasps with a spacing of 1500. After the concrete pouring has a certain strength, start to arrange 18# cantilevered I-beam 1 with a spacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com