Edge banding conveying device for door sheet edge banding procedure

A conveying device and edge banding technology, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc. It can solve the problems of being attached to the door frame, large vibration, and greatly affecting the effect of edge banding. Achieve the effect of smooth transportation and ensure the quality of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

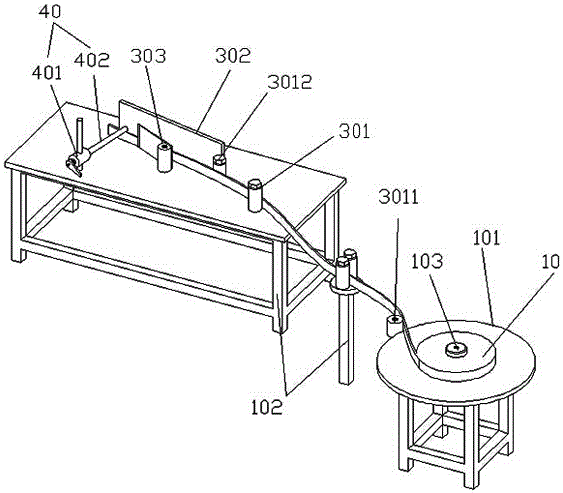

[0014] as attached figure 1 The shown edge banding conveying device for door panel edge sealing includes a conveying tray 101 and a conveying frame 102 arranged between the conveying tray 101 and the edge sealing device. The rotating shaft 103, the edge strip disc 10 is fixed on the rotating shaft 103. The conveying frame 102 is provided with guiding components, including several vertical guide rollers 301 arranged in a staggered manner on the conveying frame 102 and a guide plate 302 arranged on the conveying frame 102 and used for attaching the edge banding to the surface of the guide plate 302 The pressing member 303, the number of vertical guide rollers 301 is indefinite according to the length of the conveying line, usually one is set every 10 centimeters or so, but at least includes the first guide roller 3011 and the second gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com