wheel suspension for vehicles

A technology of wheel suspension and wheel frame, which is applied in the field of wheel suspension for vehicles, and can solve the problems of increasing the weight of wheel suspension and occupying construction space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

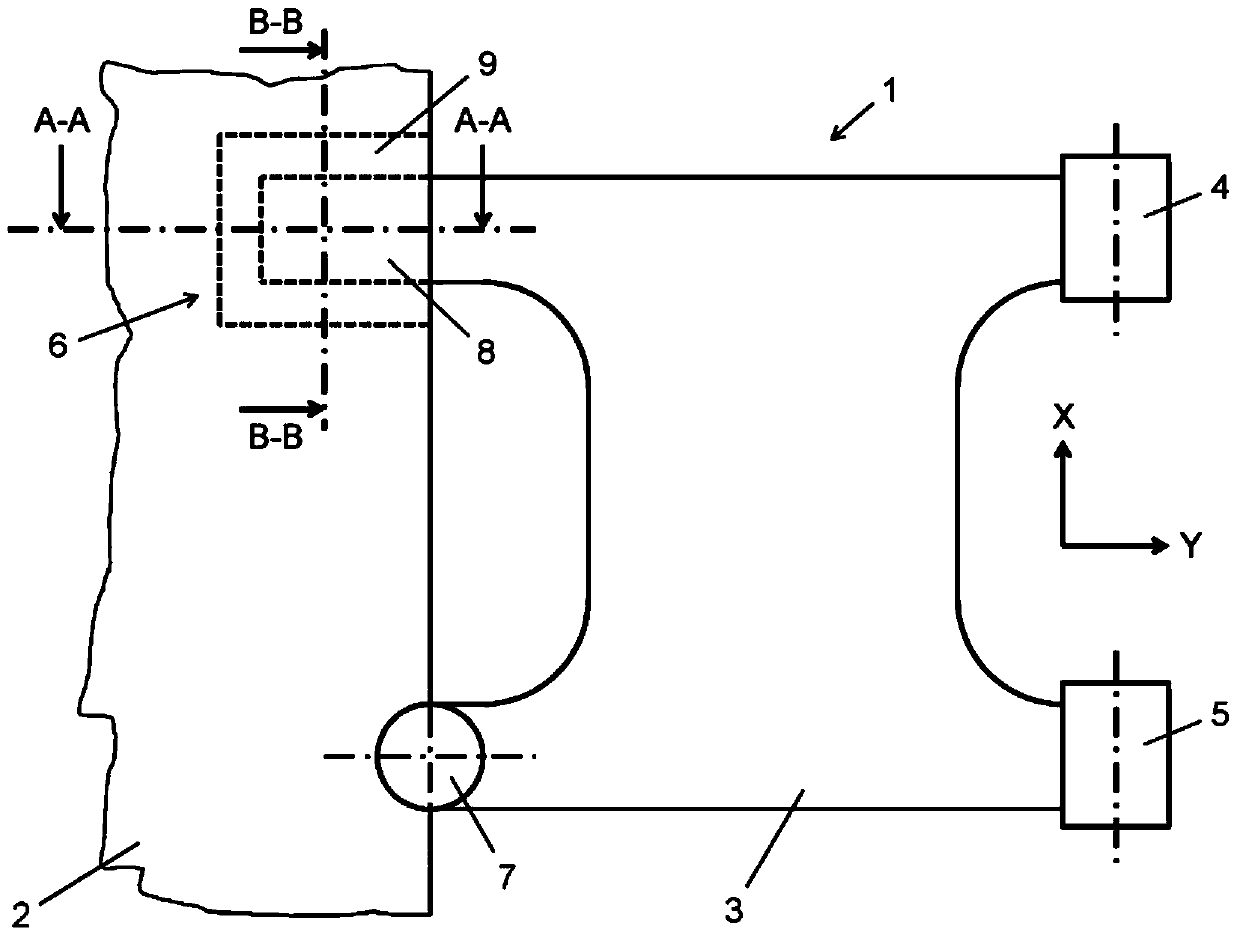

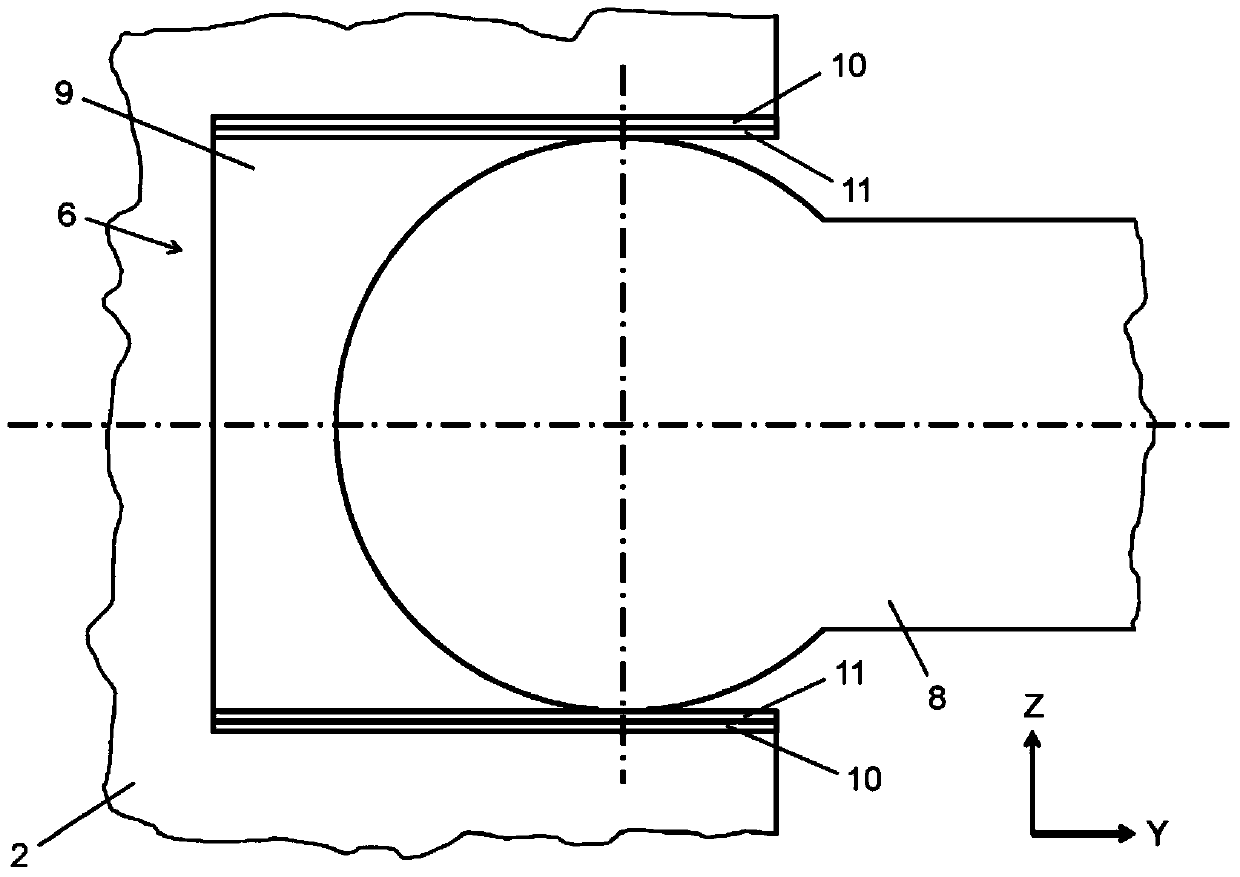

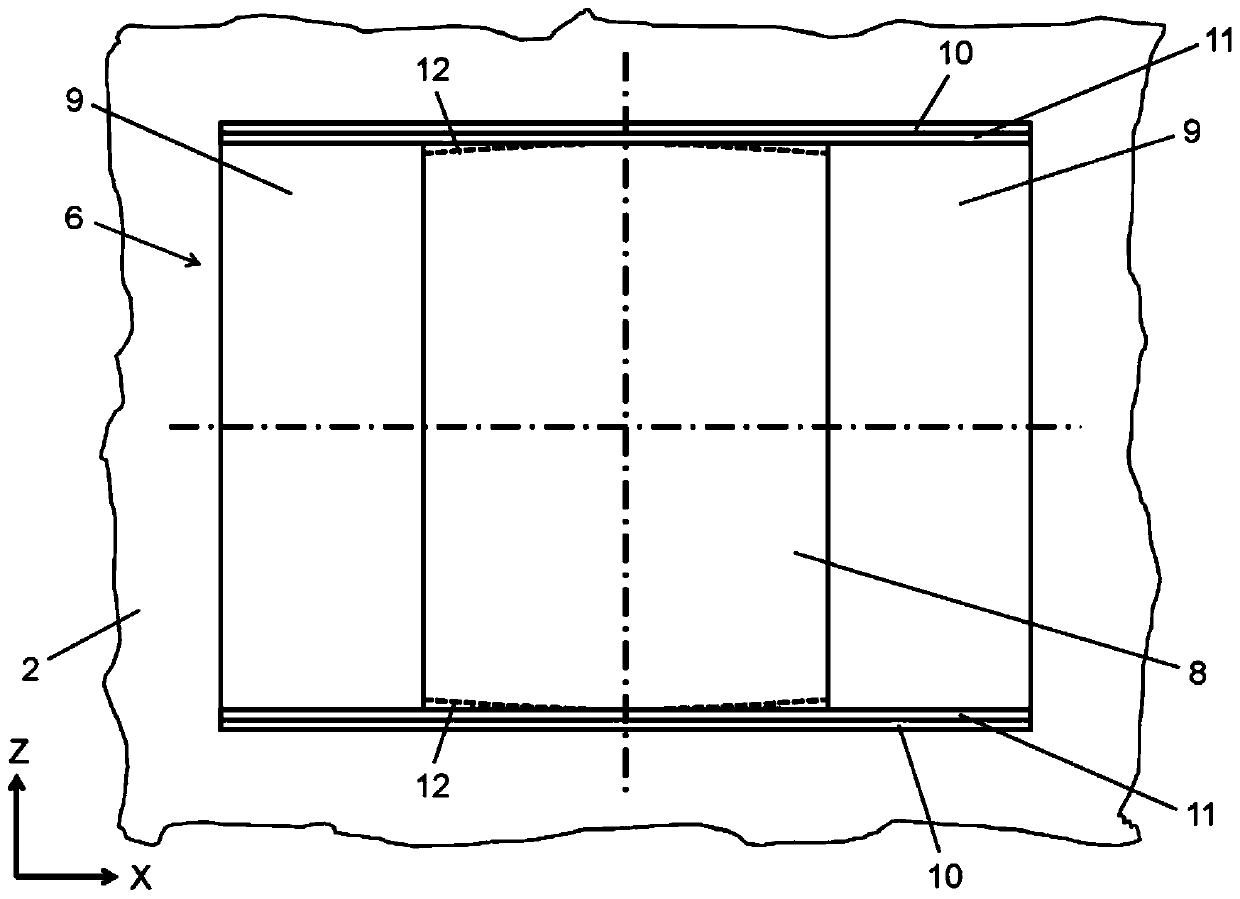

[0022] figure 1 A plan view of a wheel suspension 1 according to the invention for a vehicle, in particular for a motor vehicle, is shown. exist figure 1 The spatial directions X and Y shown in represent a direction parallel to the longitudinal axis of the vehicle (direction X) and a direction parallel to the transverse axis of the vehicle (direction Y).

[0023] as from figure 1 As can be seen, the wheel suspension 1 comprises a wheel carrier 2 which rotatably supports a wheel (not shown). The wheel carrier 2 is pivotally mounted on a torsionally rigid transverse control arm 3 which is in turn pivotally mounted on the vehicle superstructure (not shown) or a subframe connected to the vehicle superstructure (also not shown) on. For this purpose, the transverse control arm 3 has two control arm bearings 4 (front control arm bearing on the superstructure side in the direction of vehicle travel) and 5 (rear control arm bearing on the superstructure side in the direction of veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com