Multi-sized dental implant body general spiral pushing structure

A dental implant, multi-size technology, applied in the fields of dental implant, dentistry, dental repair, etc., can solve the problems that affect the convenience and appropriateness of dental implant implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

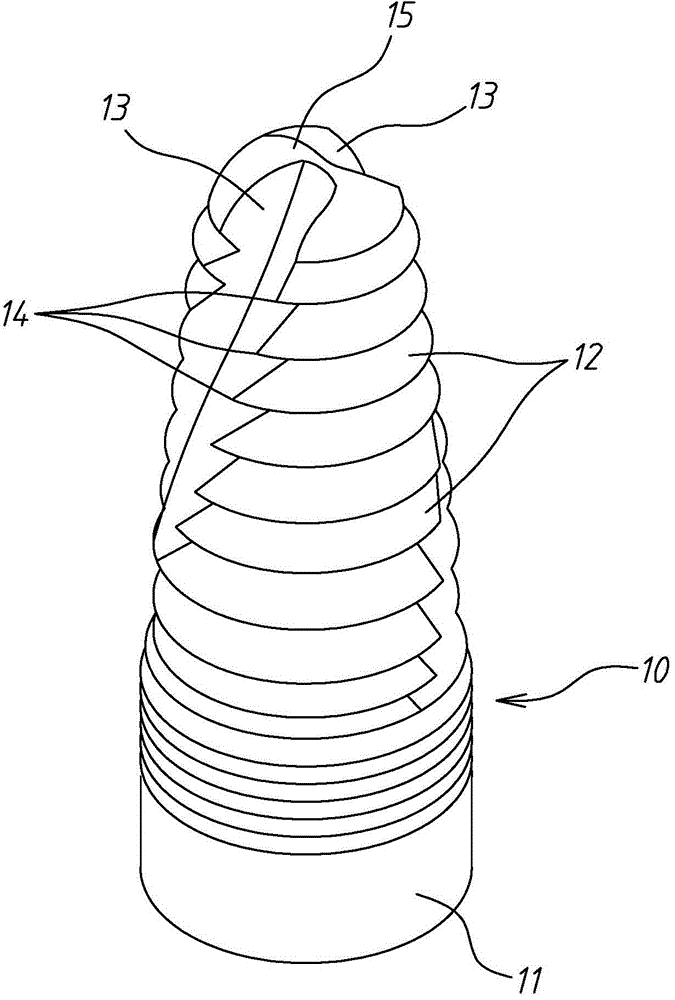

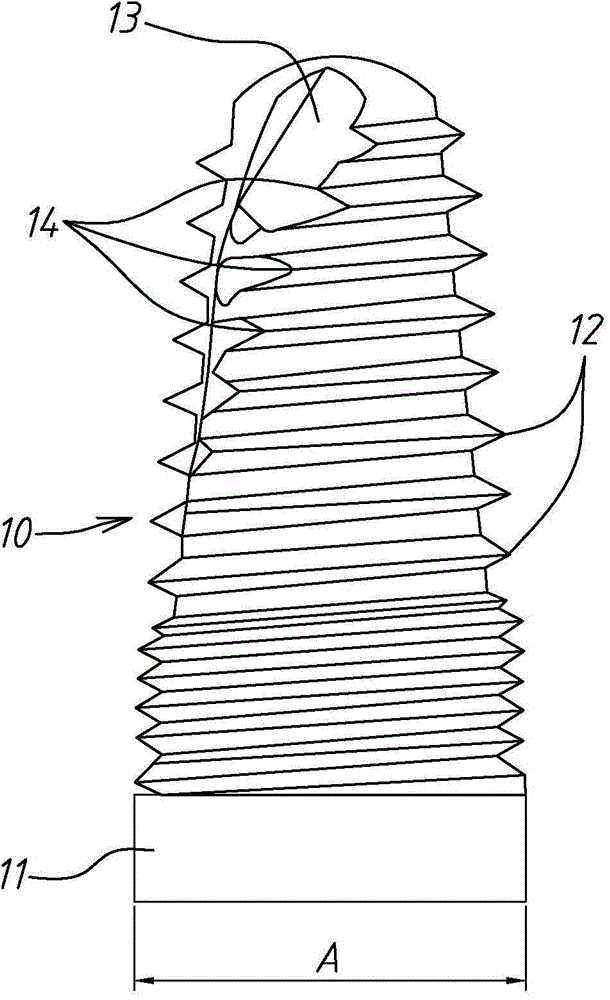

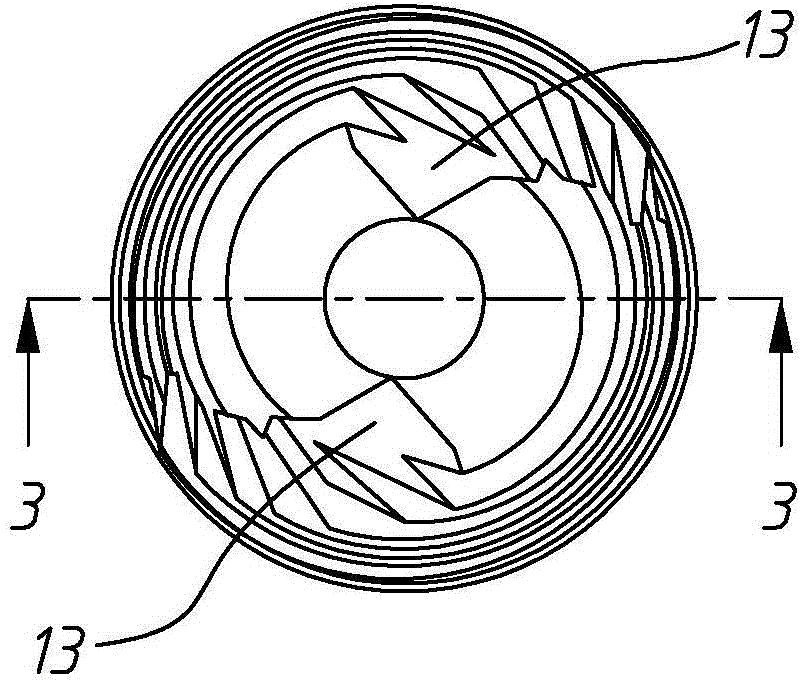

[0026] Such as Figure 1 to Figure 4 As shown, this embodiment is a smaller size (such as 3.75mm) dental implant body 10, the material of this type of dental implant body can be zirconium dioxide, and the dental implant body 10 is provided with a base portion 11 with a specific size and diameter A, The diameter A matches the width of the cementum of different sizes, and the size is about 3mm to 7mm. In the following examples Figure 1 to Figure 4 The diameter A is 3.75mm, Figure 5 to Figure 6 The diameter B is 4.5mm, Figure 7 to Figure 8 The diameter C is 5.25mm, but this is only for convenience of illustration, not limitation.

[0027] please refer again Figure 1 to Figure 4 , the structure of the dental implant 10 includes the required threaded portion 12 formed from the bottom to the top by the base part 11 in a manner of gradually reducing the diameter, and a plurality of sets matching the diameter A are set to penetrate from the bottom to the top The equally spaced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com